The Commonwealth of Nations Group 23 Khashchevatskyi Mychailo Language Instructor: Shevchuk T. V.

19 09.30 Shevchuk RUS 0

description

Transcript of 19 09.30 Shevchuk RUS 0

-

ABB Group February 19, 2014 | Slide 1

Propulsion solution to enable Arctic LNG transportation in Russia

Russia Arctic Offshore, February 2014, Moscow, Russia

-

ABB Group February 19, 2014 | Slide 2

ABB

1970-1980 , /

1980- 1993 , , .

1994- 2000 ,

2000 ABB 6,6 Samsung BP.

Nov 2006 - (DFDE) Gaz De France STX France (Chantiers de LAtlantique).

2013 / 111 , 70 ABB.

-

ABB Group February 19, 2014 | Slide 3

ABB history as supplier to LNG vessels

1970-1980 Supplier of total LV Electrical package to LNG vessels being built in Norway/Poland and Germany for Leif Hegh and Gotaas Larsen

1980- 1993 Nearly all vessels built in Japan with Japanese equipment

1994- 2000 Marketing of high voltage system as a way of reducing building cost and increase safety of the electrical installation

2000- Winning the first order in the world for 6.6kV Power System at Samsung for BP

Nov 2006 First order for Dual Fuel Diesel Electric Propulsion system for Gaz De France at STX France (Chantiers de LAtlantique)

March 2013 Delivery / on order MV electrical systems to 111 LNG Carriers, Of this 70 LNGC is equipped with ABB Electrical Propulsion and Power System.

-

ABB Group February 19, 2014 | Slide 4

( )

ABB

2006 .,

29 DFDE

ABB 14 .

, 2013-2015

4

41 ,

ABB.

ABB

-

ABB Group February 19, 2014 | Slide 5

Customer benefits Steady running in Gas Mode (Power Mode)

High system efficiency

High reliability & availability

One equipment manufacturer, all ABB

Global service support

Since first ship delivery in 2006, 29 DFDE LNGs

with ABB have been delivered to 14 ship owners.

In addition there are 4 more new owners that will

get their ships within the next years out of the 41

LNGCs on order with ABB.

ABB s solution Power Generation & Distribution

Electric propulsion system

Electric propulsion motors

Variable speed propulsion drives

Propulsion supply transformers

Main Swtichboards

Propulsion control system

Experienced project team

The natural choice

-

ABB Group February 19, 2014 | Slide 6

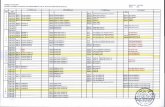

ABB ( ) 41

BP SHI

British Gas SHI

A.P.Mller SHI

Exmar Belgium SHI

Knutsen OAS Izar, Spain

Teekay Izar, Spain

Elcano Izar, Spain

Shell DSME

North West Shelf DSME

Bergesen DSME

Teekay DSME

Statoil - Leif Hoegh/MOL MHI, Japan

China LNG Shell Hudong, China

-

ABB Group February 19, 2014 | Slide 7

ABB Marine Reference List (Steam propulsion) 41 Medium Voltage Power Systems - In operation

BP SHI

British Gas SHI

A.P.Mller SHI

Exmar Belgium SHI

Knutsen OAS Izar, Spain

Teekay Izar, Spain

Elcano Izar, Spain

Shell DSME

North West Shelf DSME

Bergesen DSME

Teekay DSME

Statoil - Leif Hoegh/MOL MHI, Japan

China LNG Shell Hudong, China

-

ABB Group February 19, 2014 | Slide 8

ABB ( DFDE) 29

Teekay (Angola/MiNT) 4 , SHI ( 2011)

Brunei LNG 2 , DSME ( 2011)

STX Pan Ocean 1, Hanjin ( 2010)

Elcano 1 , STX ( 2010)

Gaslog - 2 , SHI ( 2010)

Leif Hoegh 2 . , SHI ( 2009/2010)

ILTC - 1 , SHI ( 2009)

BW Gas - 2 , DSME ( 2009)

MISC - 2 , MHI ( 2009)

K-Line - 3 SHI ( 2008/2009)

AP Mller - 6 , SHI ( 2008/2009/2010)

Gaselys NYK CAT ( 2007)

Provalys Gaz de France CAT ( 2006)

Pioneer Knutsen KOAS, 1.1003 Bijlisma ( 2003)

-

ABB Marine Reference List (DFDE propulsion) 29 Electric Propulsion Systems - In operation

Teekay (Angola/MiNT) 4 vessels, (Delivered 2011)

Brunei LNG 2 vessel, (Delivered 2011)

STX Pan Ocean 1 vessel, (Delivered 2010)

Elcano 1 vessel, (Delivered 2010)

Gaslog - 2 vessels, (Delivered 2010)

Leif Hoegh 2 SRV vessels, (Delivered 2009/2010)

ILTC - 1 vessels, (Delivered 2009)

BW Gas - 2 vessels, (Delivered 2009)

MISC - 2 vessels, (Delivered 2009)

K-Line - 3 Vessels (Delivered 2008/2009)

AP Mller - 6 vessels, (Delivered 2008/2009/2010)

Gaselys NYK (Delivered 2007)

Provalys Gaz de France (Delivered 2006)

Pioneer Knutsen KOAS, 1.100m3 (Delivered 2003)

ABB Group November 2012

-

ABB Group February 19, 2014 | Slide 10

ABB Marine ( DFDE) 41 ( ABB Marine)

Chevron 6 SHI ( 14/15)

Gaslog 10 SHI ( 13/14/15)

Golar LNG 9 SHI ( 13/14/15)

Golar FSRU 2 SHI ( 13)

Thenamaris 3 SHI ( 13/14)

Sovcomflot 4 STX ( 13/14)

BW Maritime 3 HHI ( 13/14)

Alpha Tankers 2 STX ( 14/15)

Brunei LNG 2 HHI ( 14/15)

-

ABB Marine Reference List (DFDE propulsion) 41 LNG Carriers (ABB Marine current order book)

Chevron 6 vessels (Delivery 14/15)

Gaslog 10 vessels (Delivery 13/14/15)

Golar LNG 9 vessels (Delivery 13/14/15)

Golar FSRU 2 vessels (Delivery 13)

Thenamaris 3 vessels (Delivery 13/14)

Sovcomflot 4 vessels (Delivery 13/14)

BW Maritime 3 vessels (Delivery 13/14)

Alpha Tankers 2 vessels (Delivery 14/15)

Brunei LNG 2 vessels (Delivery 14/15)

ABB Group November 2012

-

ABB Group February 19, 2014 | Slide 12

ABB MARINE Scope of supply and origin

-

ABB Group February 19, 2014 | Slide 13

ABB

ABB

(95-98% ABB)

,

-

ABB

/

/

-

ABB Group February 19, 2014 | Slide 14

ABB as a TOTAL System Supplier to the Marine Market

Our Customers

Oil

Company/

Charterer

Marine Consultants

& Designers

Ship Owner/

Operator

Ship Yard

OEMs

ABB Products LNG Power Systems (95-98% ABB products)

Full system design,

integration commissioning

and service by engineers

with long experience on the

ABB equipment.

-

ABB Group February 19, 2014 | Slide 15

ABB Marine

,

, ,

,

- Resibloc

- Azipod XO & VI

,

- () Azipod C

-

,

,

,

,

- ()

-

-

,

,

- ()

, - ()

-

ABB Group February 19, 2014 | Slide 16

ABB Marine Equipment Manufacturing locations

Tallinn, Estonia

Vittuone, Italy Dalmine, Italy

Shanghai, China

Transformers

- Resibloc

Motors & Generators

-Synchronous

Azipod XO & VI

Motors, Asynchronous

Drives

- LV

Generators

- Synchronous

Motors

Synchronous (induction)

Azipod C

Switchboards

- MV

Turgi, Switzerland

Brillon,Germany

Lugano, Switzerland

Helsinki,Finland

Motors

- Asynchronous (induction)

Drives

- MV

Transformers

Cast resin

Generators

- Synchronous

Skien, Norway

Switchboards

- LV

Vsters, Sweden

Motors

- Asynchronous (induction)

Osasco, Brazil Motors - Asynchronous (induction)

-

ABB Group February 19, 2014 | Slide 17

, Installed base with ABB systems

SCF (OSVs) x 3

Riber x 1

Norilsk Nickel x 6

Sovcomflot-Varandey x 3

SCF/SWIRE x 3

Gazflot x 2

Wagenborg x 2

MSCO x 2

Rosatomflot ice-breakers x 2 Under new-bulidiing stage:

RMP LK-25 W.Arctic Rescue vessels (2) W.Arctic and Sakhalin

- LBU Marine

locations

-

ABB Group February 19, 2014 | Slide 18

Electrical propulsion system configurations for LNG tankers

-

ABB Group February 19, 2014 | Slide 19

1

3

2

4

. .

FP

P

Bo

ile

r 6

5 t

on

/h

Bo

ile

r 6

5 t

on

/h

HP

Ste

am

T

urb

ine

LP

R

E

V

G

G

G

6,6 , 60 6,6 , 60

3500 3500

3500

M M

440 -

M

440

M

440

M M

M

M M M

LD

HD

440

M M M M M

LD

M HD

FP

P

Bo

ile

r 6

5 t

on

/h

Bo

ile

r 6

5 t

on

/h

HP

Ste

am

T

urb

ine

LP

R

E

V

G

G

G

6,6 , 60 6,6 , 60

3500 3500

3500

M M

440

-

M

440

M

440

M M

M

M M M

1-4

LD

HD

440

M M M M M

LD

M HD

5-8

G G

6,6 , 60 6,6 , 60

4500

M M M M

440

M M

440

M M

440

M M M M M M M M M M M M

1-4

LD .

HD .

440

M M M M M M M M M M

LD .

M M

HD .

G G

4500

G G

4500

G G

4500

~ ~

~ ~

~ ~

~ ~

2 - S

tro

ke E

ng

. w

/GI

2 - S

tro

ke E

ng

. w

/GI

M M M M

Re. Liq. . Re. Liq. .

~ ~

~ ~

M M

~ ~

~ ~

M M

Fuel Gas .

1-4

G

6,6 , 60 6,6 , 60

M M

440

M

440

M

440

M M M M M M

LD

.

HD

. 440

M M M M M

LD

.

M

HD

.

G G G

~ ~

~ ~

2 - S

tro

ke E

ng

ine

2 - S

tro

ke E

ng

ine

M M

Re. Liq . . Re. Liq ..

G G

6,6 , 60 6,6 , 60

M M M M M M

440

M M

440

M M M M M M M M M M M M

LD

.

HD

. 440

M M M M M M M M M M

LD

.

M M

HD

.

G G G G G G

~ ~

~ ~

~ ~

~ ~

2 - S

tro

ke E

ng

ine

2 - S

tro

ke E

ng

ine

M M M M

Re. Liq . Re. Liq . .

G

6,6 , 60 6,6 , 60

11000

M M

440

M

440

M

440

M M M M M M

LD

HD

440

M M M M M

LD

M

HD

G

11000

G

11000

G

5500

~ ~

~ ~

M M

G G

6,6 , 60 6,6 , 60

11000

M M M M M M

440

M M

440

M M M M M M M M M M M M

LD

HD

440

M M M M M M M M M M

LD

M M

HD

G G

11000

G G

11000

G G

5500

~ ~

~ ~

~ ~

~ ~

M M M M

1-4

-

-

-

-

-

-

-

-

-

5-8

-

-

-

5-8

5-8

-

ABB Group February 19, 2014 | Slide 20

FP

P

Bo

ile

r

65

to

n/h

Bo

ile

r

65

to

n/h

HP

Ste

am

Tu

rbin

e

LP

R E V

G

G

G

6,6 kV, 60Hz 6,6 kV, 60Hz

3500 kW 3500 kW

3500 kW

M M

440V Ballast

Pump

Bow

Thruster

M

440V

M

Ballast

Pump

Ballast

Pump

440V

M M

M

MMM

Cargo Pump 1-4 LD

Comp

HD

Comp440V

MMMM

Cargo Pump 5-8

M

LD

CompM

HD

Comp

FP

P

Bo

ile

r

65

to

n/h

Bo

ile

r

65

to

n/h

HP

Ste

am

Tu

rbin

e

LP

R E V

G

G

G

6,6 kV, 60Hz 6,6 kV, 60Hz

3500 kW 3500 kW

3500 kW

M M

440V Ballast

Pump

Bow

Thruster

M

440V

M

Ballast

Pump

Ballast

Pump

440V

M M

M

MMM

Cargo Pump 1-4 LD

Comp

HD

Comp440V

MMMM

Cargo Pump 5-8

M

LD

CompM

HD

Comp

G

6,6 kV, 60Hz 6,6 kV, 60Hz

M M

440V Ballast

Pump

Bow

Thruster

M

440V

M

Ballast

Pump

Ballast

Pump

440V

M M MMMM

Cargo Pump 1-4 LD

Comp.

HD

Comp.440V

MMMM

Cargo Pump 5-8

M

LD

Comp.

M

HD

Comp.

G G G

~~

~~

2-S

tro

ke

En

gin

e

2-S

tro

ke

En

gin

e

M M

Re. Liq. Comp. Re. Liq. Comp.

GG

6,6 kV, 60Hz 6,6 kV, 60Hz

MM MM

440V Ballast

Pump

Bow

Thruster

MM

440V

MM

Ballast

Pump

Ballast

Pump

440V

MM MM MMMMMMMM

Cargo Pump 1-4 LD

Comp.

HD

Comp.440V

MMMMMMMM

Cargo Pump 5-8

MM

LD

Comp.

MM

HD

Comp.

GG GG GG

~~

~~

~~

~~

2-S

tro

ke

En

gin

e

2-S

tro

ke

En

gin

e

MM MM

Re. Liq. Comp. Re. Liq. Comp.

G

6,6 kV, 60Hz 6,6 kV, 60Hz

11000 kW

M M

440V Ballast

Pump

Bow

Thruster

M

440V

M

Ballast

Pump

Ballast

Pump

440V

M M MMMM

Cargo Pump 1-4 LD

Comp

HD

Comp440V

MMMM

Cargo Pump 5-8

M

LD

Comp

M

HD

Comp

G

11000 kW

G

11000 kW

G

5500 kW

~~

~~

M M

GG

6,6 kV, 60Hz 6,6 kV, 60Hz

11000 kW

MM MM

440V Ballast

Pump

Bow

Thruster

MM

440V

MM

Ballast

Pump

Ballast

Pump

440V

MM MM MMMMMMMM

Cargo Pump 1-4 LD

Comp

HD

Comp440V

MMMMMMMM

Cargo Pump 5-8

MM

LD

Comp

MM

HD

Comp

GG

11000 kW

GG

11000 kW

GG

5500 kW

~~

~~

~~

~~

MM MM

1Steam

Turbine

Propulsion

3Two stroke

propulsion

with Gas

Injection

2 Two-stroke

propulsion

with

Reliquification

4Dual Fuel

Electric

Propulsion.

LNGC Propulsion Concepts with Shaftline

GG

6,6 kV, 60Hz 6,6 kV, 60Hz

4500 kW

MM MM

440V Ballast

Pump

Bow

Thruster

MM

440V

MM

Ballast

Pump

Ballast

Pump

440V

MM MM MMMMMMMM

Cargo Pump 1-4 LD

Comp.

HD

Comp.440V

MMMMMMMM

Cargo Pump 5-8

MM

LD

Comp.

MM

HD

Comp.

GG

4500 kW

GG

4500 kW

GG

4500 kW

~~

~~

~~

~~

2-S

tro

ke E

ng

. w

/GI

2-S

tro

ke E

ng

. w

/GI

MM MM

Re. Liq. Comp. Re. Liq. Comp.

~~

~~

MM

~~

~~

MM

Fuel Gas Comp.

-

ABB Group February 19, 2014 | Slide 21

(100%)

( 7500 )

-

ABB Group February 19, 2014 | Slide 22

Fuel consumption

relative to Steam

Turbine system

(100%)

Fuel Consumption (based on 7500h yearly operation)

Comparison study Fuel Consumption

0

10

20

30

40

50

60

70

80

90

100

Steam Two St. w/reliq Two St. w/GI DF EP Value

Value

HFO/MDO

)Aux/Pilot(

HFO

Gas

-

ABB Group February 19, 2014 | Slide 23

( 7500 )

-

ABB Group February 19, 2014 | Slide 24

Emissions (based on 7500h yearly operation)

Comparison study Emissions

0

10

20

30

40

50

60

70

80

90

100

Steam Two St. w/reliq Two St. w/GI DF EP Value

Value

CO2

NOX

SO2

-

ABB Group February 19, 2014 | Slide 25

/. .

(.)

LNGC

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

Electric Propulsion

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

Electric Propulsion

-

ABB Group February 19, 2014 | Slide 26

Propulsion Efficiency

Steam Turbine

Diesel/Dual Fuel

Mech. Propulsion

High Efficiency

Steam Turbine

Gas Turbines

(Comb. Cycle)

LNGC

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

Electric Propulsion

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35

Propulsion power [MW]

Eff

icie

nc

y [

%]

Electric Propulsion

Electric Propulsion

-

ABB Group February 19, 2014 | Slide 27

(5-6 )

=>

:

. 70-90%

-

ABB Group February 19, 2014 | Slide 28

Benefits of DF Electrical Propulsion for LNGC

High efficiency over whole speed range

Lower Fuel Consumption

Environmental friendly

Lowest Emissions

Less total installed power.

Use the same power plant for propulsion and cargo handling.

Flexibility in location of equipment

Space saving and optimizing of ship design.

Low pressure Gas Fuel Supply (5-6 bar)

Safety

Variable speed drives

Ensures that full torque is available for the whole speed range and full power for negative RPM => improving maneuverability and crash stop situations.

Redundancy in electrical equipment:

Maintain approx 70-90% of full speed with single failure.

Perform maintenance at normal operation.

Fuel Flexibility fitting with future energy situations

-

El. Propulsion systems configurations for LNGC

With one propeller/two motors and Gearbox :

. Redundancy in el. system

Medium speed motors reduce weight and cost

ACS 6000 Synchronous or asynchronous, with ACS 6000 drives

-

G

6,6 , 60 6,6 , 60

11000

M M

440

M

440

M

440

M M M M M M

1-4 LD

HD

440

M M M M

5-8

M

LD

M

HD

G

11000

G

11000

G

5500

~ ~

~ ~

M M

Single skeg

-

-

-

-

-

El. Propulsion systems configurations for LNGC

With 2 propellers/motors:

, Redundancy in el. system, and also in propulsion system

( / ) With reduction gear / without (medium / low speed)

( ) ACS 6000. Synchronous or asynchronous, with ACS 6000 drives

-

LNG Carriers

G

6,6 , 60 6,6 , 60

11000

M M

440

M

440

M

440

M M M M M M

1-4 LD

HD

440

M M M M

5-8

M

LD

M

HD

G

11000

G

11000

G

5500

~ ~

~ ~

M M

Double skeg

-

-

-

-

-

El. Propulsion systems configurations for LNGC

Azipod With several propeller with Azipod:

, High power and high redundancy in el. system and propulsion system

, / . Improved maneuverability at entering/exiting ports. Space saving.

, ( (DAS) Optimal efficiency both in open water and in ice (Double Action Ships)

-

NG Azipod propulsion

G

6,6 , 60 6,6 , 60

8400

450

M

450

M

450

M M M M M M

1-4 LD

HD

450

M M M M

5-8

M

LD

M

HD

G

11250

G

11250

G

11250

~ ~

~ ~

~ ~

G

8400

G

11250

M

6,6 , 60 6,6 , 60

Azipod

0-15000 Azipod

0-15000

Azipod

0-15000

M

-

-

-

-

-

ABB Group February 19, 2014 | Slide 35

AZIPOD AZIPOD Azipod propulsion for Arctic tankers

-

-

, , LU6 (SHI) 2 Azipod 10

, LU6 (

) 2 Azipod 8,5

Tempera Mastera 1 A Super DA, 1 Azpod 16

Uikku Lunni 1 A Super 1 Azipod 11,4

(Nordic Yards), 1 Azipod 13

-

Latest Experience in Icebreaking DE Tankers

Vasily Dinkov, Kapitan Grotskiy

& Timofei Guzhenko, LU6 (SHI)

2 x 10 MW Azipod propulsion

MT Mikhail Ulvanov &

MT Kiril Lavrov, LU6 (Admirality)

2 x 8,5 MW Azipod propulsion

MT Tempera & Mastera 1 A Super DA, 1 x 16 MW Azipod

MT Uikku & Lunni 1 A Super 1 x 11,4 MW Azipod propulsion

MT Enisei Norilsk Arctic Oil Tanker (Nordic Yards), 1 x 13 MW Azipod propulsion

-

ABB Group February 19, 2014 | Slide 38

LNGC concepts - Yamal

Azipod FP

5,6 13000

13 MW

8,0 18000 FPP 18 MW

Azipod

5,6 13 000

13MW

3 AZIPOD

2 AZIPOD 1

2 AZIPOD

-

19-Feb-14 Slide 39

Aker Arctic DAS

Yamal LNG 170 ... 170k Arctic LNG carriers for year round transportation

-

Double Acting Vessel Comparison in Operation Point of View

-

DAS Vessel Speed vs. Ice Thickness an example with DA vessel

-

Hydrodynamics with a conventional shaftline

ABB Group February 19, 2014 | Slide 42

Pushing propeller

- , . Uneven wakefield for the propeller due to disturbances from hull, strut etc.

Added resistance from appendages such as rudders, shaft brackets and stern thrusters , ,

-

Hydrodynamics with Azipod propulsion

ABB Group February 19, 2014 | Slide 43

Optimum wakefield due to Pulling propeller Lack of shaft line and shaft

brackets etc.

Location of the pod unit

, Due to power plant principle and lack of long shaftlines there is freedom to optimize the hull form

No separate stern thrusters and rudders

-

( ) Stern First Operation (Double Acting Ship)

ABB Group February 19, 2014 | Slide 44

Propeller suction effect removes ice blocks from the ridge keel and breaks the

ridge by removing the foundation of the ridge

Capable to operate without ramming

Propeller induced water flow lubricates the ice/snow and reduces friction to the

ship hull

- - Possible to optimize stern for icebreaking and bow for open water

In stern first operation bigger clearance between hull and propeller tip

Less need for assisting icebreakers

-

Azipod VI Azipod VI for ice-going vessels

New products

Azipod VI2300L New Azipod VI2300L

-

Azipod VI2300L

-

New Azipod VI2300L

Hydraulic power pack

Stainless steel propeller

Hydraulic steering motors

Electric motor

inside the pod

Cooling Unit

Slipring Unit

-

Azipod VI Azipod VI products

VI2300L

A

zip

od

(

)

Azip

od

uit

th

rust,

kN

Azipod () Azipod unit power, kW

* ABB

-

Azipod VI2300L New Azipod VI2300L project

Azipod Azipod "VI2300L"

Increased strut height Increased power

New electrical motor, with increased max. torque Increased propeller diameter More

robust design for high ice class

-

Scenario analysis, for extreem ice loads

-

Structural analysis for global and local ice loads

-

Case study Propeller design for Arctic LNG Carrier

-

Scope of the study

Azipod VI2300L A propeller for a Arctic LNGC Carrier has been designed Upgraded ABB Azipod VI2300L

-

Ship and propulsion concept

Ship data

170 m3 LNG Carrier

L=285m, B=50m, T=11.7m

Propulsion

3x15MW Azipod

Performance

21 21kn in ice free waters

2.0 , 2.4 Ice level thickness 2.0m in ahead condition, 2.4m astern

-

/ Challenge

( 21,5 ) Two propeller design points that are far away from each other (Bollard and 21.5kn)

, , .. Vessel picks up cargo from very demanding arctic areas where independent operation in ice is necessary -> high Ice class

, / Thus high thrust in icebreaking conditions needed and also high speed in transit in open water conditions

90% , 90% of operation in ice free waters means that fuel economy is very important

: Two design conditions were selected:

15 ( = 0 ) 15MW at bollard pull condition (Vs=0kn)

21.5 (15 ) Trial speed 21.5kn (15MW)

-

ABB Group February 19, 2014 | Slide 56

Dimensioning of structures Propeller

( ) Stainless steel (in high ice class pods)

Fixed pitch

ARC7 Dimensioning according to ice class ARC7

Detachable blades

180% Overtorque 180 %

-

Design process

Initial geometry was created from existing project

Design made for side Azipod

Procal Procal software was used to analyse:

/ Efficiency estimation

Loads

Cavitation

Model tests

Design verification

, Open water only, without ship hull

Propeller design is a generic design and will be updated according to each vessel design

The goal of this project was to design a propeller that can operate succesfully in ice free water with high speed and efficiently in heavy ice conditions

! Goal was reached!

-

Azipod VI2300L Technical advantages of upgraded Azipod VI2300L

Increased hydrodinamical efficiency

, big propeller, high torque

High torque and power in ice-going mode

max. overtorque is needed for safe and efficient operation in ice

Increased stability in course keeping

long pod and strut

Most of operational possibilities improved

More freedom in optimization of middle propeller

-

ABB obtains proven solutions for different Oil & Gas projects in Russia

Sakhalin: 6 ZIPOD Successful operation of 6 ice-breakers

equipped with Azipods

4 4 new ice-breakers for SEIC in tender process

New ice-breakers will be needed for fields Yuzhny Peltun and Kirinskoye

Caspian sea:

Successful operation of ice-breakers Arkticaborg class

New ice-going vessels are needed for Kashagan field

Russian Western Arctic: 15 ZIPOD Successful operation of 15

ice-going vessels equipped with Azipods

New ice-breakers needed for Kara and Pechora seas

Various ice-breaking vessels for Yamal project under bid Tankers and LNGC

-

ABB Group February 19, 2014 | Slide 60