13818976 New Electrocatalysts by Rial

Transcript of 13818976 New Electrocatalysts by Rial

-

8/7/2019 13818976 New Electrocatalysts by Rial

1/29

Annu. Rev. Mater. Res. 2003. 33:55779doi: 10.1146/annurev.matsci.33.022802.090953

Copyright c 2003 by Annual Reviews. All rights reserved

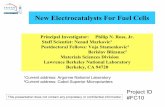

NEW ELECTROCATALYSTS BY COMBINATORIALMETHODS

Eugene S. Smotkin and Robert R. Daz-MoralesDepartment of Chemistry, University of Puerto Rico at Rio Piedras, San Juan,

Puerto Rico 00931; email: [email protected]; [email protected]

Key Words fuel cells, array screening, heuristic rules

s Abstract Combinatorial methods provide a means for accelerating the discoveryof fuel cell catalysts. The first example of parallel fuel cell catalysts screening was anindirect method that used fluorescent chemosensors to detect changes in pH in proxim-ity to electrocatalyst spots. Serial direct electrochemical methods have been developedthat use voltammetry, chronoamperometry, and scanning electrochemical microscopy.An array fuel cell screens catalysts simultaneously, using high-performance fuel cellcomponents. Heuristic models based on mechanistic and spectroscopic studies pro-vide guidance for library development, and detailed studies of discovered catalysts

can help to refine these models. The remaining challenges are the development ofhigh throughput synthetic methods that can enable the use of discovery level and fo-cus level screening. Until these synthetic methods are developed, a greater emphasisshould be placed on smaller libraries with design of experiment strategies leveragedwith informatics and data mining.

INTRODUCTION

Combinatorial Discovery of Heterogeneous CatalystsTraditional catalyst discovery methods are labor intensive and involve time-con-

suming trial and error procedures. Combinatorial synthetic methods are being de-

veloped to process large libraries that, if combined with high throughput screening

integrated with data mining and predictive modeling, are expected to accelerate

the catalyst discovery process. Over 50 years ago, Mittasch first applied combi-

natorial approaches to the discovery of heterogeneous catalysis, using arrays of

reactors to screen large libraries of catalysts for the synthesis of NH3 from H2 and

N2 (1). Twenty years later, Hanak applied combinatorial methods to optimize the

compositions of superconductors (2).

Two levels of resolution typify combinatorial catalysts screening subsystems

-

8/7/2019 13818976 New Electrocatalysts by Rial

2/29

558 SMOTKIN DIAZ-MORALES

parallel or serial. Ideally, the focus screen should provide more detailed response

functions such as kinetics, selectivity, and lifetime studies. The focus subsystem

is intended to generate strong leads for further development and provide guidance

for scale-up studies.Commonly used methods in heterogeneous catalyst screening are optical and

mass spectrometric (MS) because of their broad applicability and dynamics.

Holzwarth et al. have demonstrated IR thermography as a heterogeneous, catalyst-

screening tool by taking into account different emissivities of catalyst clusters (4).

IR thermography is a fast parallel method ideally suited for down-selection of cat-

alyst candidates at the discovery level for evaluation at the focus level. Scanning

MS has emerged as a versatile method of analysis. Two basic concepts for the ap-

plication of scanning MS include transient modes (5, 6) and continuously operated

reactor arrays (7). Resonant multiphoton ionization (REMPI) give more direct in-formation but in a serial fashion. Nayar et al. developed a very rapid serial MS tech-

nique, laser-activated membrane introduction mass spectrometry (LAMIMS) (3).

LAMIMS is a discovery subsystem compromise, e.g., a very rapid serial technique

capable of complete product analysis while screening under realistic conditions.

Reddington et al. pioneered combinatorial discovery level screening for elec-

trocatalysts. Their first application was direct methanol fuel cell electrocatalysis.

The optical screening method was based on the detection of the pH drop in prox-

imity to array spots catalyzing the methanol oxidation half reaction (8). Liu &

Smotkin developed an array fuel cell for parallel focus and/or discovery levelscreening (9). The array fuel cell has the advantage of parallel catalyst evaluation

under actual fuel cell conditions at controlled temperatures, catalyst loadings, and

fuel stoichiometric ratios. Serial electrochemical methods have been developed by

Sullivan et al. (10), Jiang & Chu (11), Warren et al. (12), and Pope & Buttry (13).

Shah & Hillier have developed scanning probe methods of analysis based on the

scanning electrochemical microscope (14).

The development of high throughput screening methods requires concomitant

development of high throughput catalyst preparative methods. Senkans statement,

. . . real heterogeneous catalysts are extended solids with multiple discontinuitiesin structure and composition allowing very limited systematic variation in these

properties with overall composition, (15) is appropriate for fuel cell electro-

catalysis, where catalyst preparative methods are kinetically controlled and yield

metastable, mixed-phase materials. Thus the parameter space extends beyond com-

positional (16) and includes preparative details such as temperature, addition rates

of reagents, headspace composition, choice of reducing and oxidizing agents and

even geometric aspects of reaction vessels. The variation of these noncomposi-

tional parameters can generate hundreds of different catalysts for a unique nominal

composition.

Th Si l C ll F l C ll

-

8/7/2019 13818976 New Electrocatalysts by Rial

3/29

COMBINATORIAL ELECTROCATALYSTS 559

generate electricity. It was another 120 years before the NASA space program

demonstrated the first practical application in space flight. Approximately 160

years after Groves observation, fuel cells have still not entered the consumer

market. The transition from the space program, where highly purified H2 andO2 areused, to terrestrial applications using commodity fuels and air, awaits the discovery

of better catalysts that can accommodate the impurities included in H2 derived

from hydrocarbon-based fuels (reformate). The most studied catalyst poison is

CO, a contaminant in reformate fuel and an intermediate in direct methanol fuel

cells (DMFCs). Other concerns are sulfur-containing and nitrogenous (particularly

from autothermal reforming) catalyst poisons. Aricoetal.haveprovidedathorough

review of fuel cell catalysis (17).

Gottesfeld & Zawodzinski provide an excellent review of polymer electrolyte

membrane (PEM) fuel cell systems and catalysis (18). Figure 1 schematizes a fuelcell based on NafionTM 117 (eq wt. 1100, thickness .007 inch). The catalytic layer

and the gas diffusion layers (GDLs) are 10 and 150 m thick, respectively. The

heart of the fuel cellthe PEM sandwiched between the electrocatalytic layers

is the membrane electrode assembly (MEA). Another practice is to catalyze the

GDLs, which are then pressed against PEM (i.e., GDL-integrated MEA) dur-

ing fuel cell assembly. The single cell is completed by current-collecting plates

with machined flow fields for delivery of fuel and oxidants. Reformate fuel cell

catalysts are typically supported on carbon (1 m), whereas DMFC catalysts

-

8/7/2019 13818976 New Electrocatalysts by Rial

4/29

560 SMOTKIN DIAZ-MORALES

are unsupported. In most cases, the catalysts, incorporated into alcoholic inks that

include solubilized polymer electrolyte, are decal-transferred to the polymer (19)

or applied to the GDLs. The finalized catalyst environment has no mobile anions.

Issues such as contact of catalyst nanoparticles with the polymer electrolyte andcontrolled hydrophobicity (to avoid cathode flooding) are inextricably linked to

the catalyst preparation method. The complex environment of fuel cell catalysts

as well as the electrode chemistries must be considered when designing screening

methods.

Reformate Fuel Cells

Significant losses arise in reformate fuel cells because of poisoning by carbon

monoxide. The effects of CO on fuel cell performance were first described by

Gottesfeld & Pafford, who described the effects of CO levels ranging between

5 and 100 ppm (20). The reforming of liquid fuels yields hydrogen with high

levels of CO. Methanol reformate is typically 25% CO2 and 1% CO. Although CO

can be removed by the combination of a water-gas-shift reactor and a preferential

oxidation unit to below a ppm, CO can be generated at the electrode surface

by insitu reduction of CO2 (the reverse water-gas-shift reaction). Combinatorial

methods are also being applied to water-gas-shift catalysts (3). PtRu is somewhat

resistant to CO poisoning but cannot tolerate transient spikes (as high as 0.1% CO)

common to fuel processors. A recent evaluation of CO poisoning on Pt suggests

that at ideal operating conditions (

-

8/7/2019 13818976 New Electrocatalysts by Rial

5/29

COMBINATORIAL ELECTROCATALYSTS 561

and electrochemical studies are being used to develop a comprehensive model that

considers d-band vacancies, geometric factors, and the chemisorption of oxygen

species (25). XAS showed that alloying in carbon-supported Pt/Cr, Pt/Co, and

Pt/Ni contracts the Pt-Pt bond distances. This would enhance a dual site mecha-nism (Equation 3). In addition, the alloying inhibits chemisorption of oxygenated

species, which are responsible for formation of the passivating layer. Toda et al.

studied sputter-deposited Pt-based alloys, including Ni, Co, and Fe, for the ORR

(25a). X-ray photoelectron spectroscopy (XPS) of the sputter-deposited alloys af-

ter electrochemical evaluation showed, without exception, no detectable alloying

components. However, supported alloy catalysts have shown high stabilities and

can retain non-noble alloying elements during 60009000 h of operation in PEM

fuel cells (24). Thus the relevance of sputter-deposited alloys that are not realisti-

cally supported is questionable. Several empirical studies have shown that first-rowtransition metals, including Cr, Co, Ni, and Fe (22, 25, 26), have promoting ef-

fects, although the optimum composition of these alloys remains unknown. In the

ideal, promoting elements are sought that maintain the proper structure and parti-

cle size while inhibiting the adsorption of passivating oxygen-containing species.

Marcovic & Ross (22) describe the anion dependence (ClO4 versus HSO

4 ) of

the performance rankings of Pt3Co, Pt3Ni, and Pt, confirming the importance of

anion adsorption on the ORR rate. They found that the ORR activation energies

for the alloys are similar to that of Pt, which suggests a common serial 4-electron

ORR mechanism. Marcovic & Ross suggest that among Pt ensemble, structural,and electronic effects, the latter is the dominating factor in Pt-OHads energetics.

The careful consideration of these models when designing combinatorial li-

braries, coupled to high throughput fundamental science enabled by in situ high

throughput screening devices, could go a long way toward advancing our under-

standing of ORR kinetics.

Direct Methanol Fuel Cells

DMFCs are based on CH3OH oxidation at anode. Although on a per mass basis

PtRu is more active when supported on carbon, the sluggish kinetics of methanol

oxidation demands high MEA catalyst loadings (4 mg cm2) that can be ac-

commodated only by unsupported catalysts (27). MEA fabrication methods must

be developed to enable the use of the more active supported catalysts. The gas

diffusion layers at the anode side, which were designed for gas fed fuel cells, must

be replaced with current-collecting diffusion layers that are optimized for liquid

feed fuel cells and supported catalyst anode layers.

Unlike H2 fuel cells, where polarization losses are primarily at the cathode,the losses at the DMFC anode and cathode are comparable. The consensus is that

methanol oxidation proceeds by a bifunctional mechanism (28 29) that involves

-

8/7/2019 13818976 New Electrocatalysts by Rial

6/29

562 SMOTKIN DIAZ-MORALES

CH bond activation

Pt-(CH3OH)ads Pt-(CH3O)ads + H++ e. 6a.

Pt-(CH3O)ads

Pt-(CH2O)ads+

H

++

e

. 6b.Pt-(CH2O)ads Pt-(CHO)ads + H

++ e. 6c.

Pt-(CHO)ads Pt-(CO)ads + H++ e. 6d.

Water adsorption

M+ H2O M-(H2O)ads. 7.

CO oxidation

Pt-(CO)ads +M-(H2O)ads Pt+M+ CO2 + 2H++ 2e. 8.

OverallCH3OH+ H2O CO2 + 6H

++ 6e. 9.

CO free pathways have been proposed but the relevance to steady-state fuel

cell performance is unclear (30, 31). Methanol oxidation kinetics is sluggish be-

cause PtRu does not adequately activate H2O (Equation 7). Crossover methanol

from the anode to the cathode hampers O2 reduction by wasting Pt sites at the

cathode for the direct reaction of methanol with O2 (severely reducing fuel ef-

ficiency), generating a mixed potential that reduces cell voltage, and producing

additional H2O that causes flooding and increases the required O2 stoichiometricratio.

Anode catalysts capable of H2O activation at more negative potentials and

cathode catalysts insensitive to methanol (permitting return of methanol to the

anode) are needed. Cathode catalysts operating at more positive potentials would

permit polarization of the anode to more positive potentials without compromising

operating cell voltages. At more positive anode potentials CH activation (Equation

6) becomes a more kinetically important consideration (32).

Methanol-insensitive cathode catalysts would improve the DMFC fuel effi-

ciency by permitting return of crossover methanol to the anode stream. This wouldexclude Pt, which effectively adsorbs methanol (Equations 6ad). Alonso-Vante

& Tributsch (33) and Alonso-Vante et al. (34) discovered methanol-tolerant non-

noble metal catalysts 15 years ago. These catalysts were originally reported

as Chevrel phases composed of Ru and Se doped with Mo and other elements.

Although chalcogenide-based catalysts have been demonstrated to be methanol

insensitive, their performance is an order of magnitude less than that of Pt. The

development of methanol-insensitive cathode catalysts would be ideally suited for

combinatorial studies.

Heuristic Models for Catalyst Library Development

-

8/7/2019 13818976 New Electrocatalysts by Rial

7/29

COMBINATORIAL ELECTROCATALYSTS 563

that do not make sense chemically. The development of platinum alloy methanol

oxidation catalysts is a good example of this approach. CO, a surface-bound in-

termediate in methanol oxidation, rapidly poisons pure Pt. Adatoms and alloying

elements such as Ru and Sn cause Pt to oxidize methanol at much lower overpo-tentials (3546), and several models have been proposed to explain this effect. The

bifunctional mechanism proposes that water (required in Equation 8) can be bound

more efficiently by oxophilic metals that alloy with or physically contact nanoscale

grains of Pt (4749). A second model involves a ligand effect, in which the d-band

occupancy of Pt is changed by alloying elements, lowering the activation barrier

for CO oxidation (29, 5052). A third model, more recently proposed, claims that

elements such as Ru and Os do not alloy with Pt but provide a mixed-conductor

hydrous oxide phase that improves contact between the Pt surface and the PEM

(53).The above models provide a starting point for library development. Ley et al.

(54) and Liu et al. (55) reported a strategy for ternary catalyst library development

based on the bifunctional mechanism. They hypothesized that Equation 8 demands

similarity between the promoter MO and the PtC bond energy of590 kJ

mol1. A plot of MO binary bond energies in proximity to the PtC bond energy

(Figure 2) suggests a component library that includes Mo, Ru, Os, Sn, and Re.

Figure 2 Ley diagram for bifunctional mechanism requiring concerted breaking of

PtC and MO bonds, where M is Pt or an alloying component. Components along

-

8/7/2019 13818976 New Electrocatalysts by Rial

8/29

564 SMOTKIN DIAZ-MORALES

Figure 3 Consideration of phase equilibria in library design. Two binary phase dia-

grams are combined to generate approximate ternary diagrams. The Ley model selects

nominal compositions near the single-phase region. Actual catalysts are mixed phase

systems. [Reprinted with permission from (55). Copyright 1996 The Electrochemical

Society, Inc.]

Ley et al. further assumed that the alloy phase was the key catalytic phase and thus

avoided compositions that significantly departed from the single-phase regimes.

They constructed approximate ternary phase diagrams from binary diagrams to

generate ternary libraries (Figure 3) and tested this idea by examining ternary

Pt-Ru-Os compositions that lay within the face-centered cubic (fcc) single-phase

region of the ternary alloy phase diagram. They correlated the effectiveness of

alloying elements with metaloxygen bond strengths and rationalized why Ru is a

more effective alloying element than Os. Ley et al. were first to show that ternary

combinations give higher activities than simple binaries in the single-phase region.

Liu et al. corroborated this with rotating disc electrode studies of Nafion-coated,

arc-melted Pt, Pt Ru, and PtRuOs electrodes (56).

COMBINATORIALMETHODS FOR ELECTROCATALYSIS

Single-Cell Versus High-Throughput ScreeningThe traditional method for optimizing fuel cell catalysts is to prepare bulk catalysts

-

8/7/2019 13818976 New Electrocatalysts by Rial

9/29

COMBINATORIAL ELECTROCATALYSTS 565

analysis can be applied to MEA-bound catalysts before and after fuel cell testing.

The success of single-cell testing requires invariant counter electrode performance.

It is convenient to operate the counter electrode as a hydrogen reference electrode in

the galvanostatic mode. In either case, reproducible water management is requiredif single-cell tests are to be comparable. The preparation of catalyst ink for MEA

preparation takes two days. Three days of electrochemical conditioning followed

by least two days of steady-state data acquisition are required to ensure steady-

state performance on uncharted catalyst libraries. The testing of ten catalysts on a

single-cell test stand, in triplicate, would take over half a year. The development

of reliable combinatorial screening methods is an alternative.

Optical Screening Methods

Reddington et al. were the first to demonstrate parallel fuel cell catalyst screen-ing (8). Their optical method is based on the fact that electrochemical half re-

actions consume or generate ions to maintain charge neutrality. Methanol oxida-

tion anode Equations 6 and 8 generate protons, and the ORR consumes protons

(Equations 2 and 4). If a chemosensor (57, 58) (an indicator molecule for the

ion of interest) is present, then its change in absorbance or emission pinpoints

the location, usually a set of individual spots in a catalyst array, where the half

reaction is occurring. Fluorescence is preferred over absorbance as a detection

method because of its greater sensitivity. An advantage of this screening method

is simplicity because of the fact that it is an intrinsically parallel technique andrequires only aqueous indicator solutions and a hand-held UV lamp. Figure 4 a,

illustrates the optical screening method with a small ternary array of Pt-Rh-Os

DMFC anode catalysts supported on a Toray carbon electrode. In this case, quinine

(pKa = 5.5), an acid-sensitive fluorescent indicator, provides a pH map of the ar-

ray. At low overpotential (Figure 4a, center frame), one spot shows the brightest

fluorescence and is ringed around by six less active spots. This region contains the

best methanol oxidation catalysts in the array. The image at the right (Figure 4a)

illustrates that at sufficiently high overpotentials, all the catalyst spots in the array

are active. Figure 4b shows robotic preparation of a 715-member array by delivery

of salts of five elements followed by borohydride reduction. At right is the top

view of the screening cell. Figure 4c demonstrates how a quaternary library can

be scanned and zoomed for refinement of the library. The array-screening cell is

an unfolded version of the quaternary compositional phase diagram. The Empire

State Building appearance results from the removal of redundant points along the

phase boundaries. This method has since been applied to cathodes (8), electrolyz-

ers (59), amperometric sensors (60), photoredox reactions (61), and anodes by

other workers (62). Two major drawbacks are that the method is indirect and does

not allow one to measure current directly, and the synthetic method for preparation

of the catalyst array is not scalable. State-of-the-art catalysts cannot be incorpo-

-

8/7/2019 13818976 New Electrocatalysts by Rial

10/29

566 SMOTKIN DIAZ-MORALES

advantage over focus level electrochemical screening. This may change if scalable

high throughput synthetic methods are developed.

Electrochemical Screening MethodsElectrochemical array screening cells have been independently developed by

Sullivan et al. (10), Jiang & Chu (11), Warren et al. (12), and Liu & Smotkin

(9). The methods of Sullivan and Warren were similar, with square grids of 64

individually addressable microelectrodes fabricated on silicon wafers by litho-

graphic methods. Sullivan et al. studied alkanethiol modified gold electrode arrays

and was able to show good correlation between the rate of electron transfer to solu-

tion phase redox couples and the optical fluorescent response using fluorescein as

an indicator. Warren et al. electrodeposited PtRu on an array of Pt electrodes and

was able to confirm by potential step experiments that PtRu 50:50 was the most

active catalyst for methanol oxidation in 0.5 M H2SO4. Chu & Gilman previously

reported similar findings (63).

Jiang & Chu developed a room-temperature array method that uses a movable

probe with an electrolyte link to a reference and more distant counter electrode

(11). Figure 5 shows the array electrode system consisting of an electronically

-

8/7/2019 13818976 New Electrocatalysts by Rial

11/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

12/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

13/29

COMBINATORIAL ELECTROCATALYSTS 569

Figure 9 XRD spectra of the four classes of catalysts, before (dotted lines) and afterarray screening (solid lines) samples obtained on the MEA after removal of the GDL

-

8/7/2019 13818976 New Electrocatalysts by Rial

14/29

570 SMOTKIN DIAZ-MORALES

TABLE 1 XRD-total pattern fitting results

Sample a/ A Displacement/deg 2

Pt (cathode) 3.9160(3) 0.009(5) 3.42313Reetz PtRu 3.8711(7) 0.253(6) 0.56467

Adam PtRu 3.8906(5) 0.352(1) 2.76493

J.M. PtRu 3.8830(8) 0.349(8) 0.61446

loading characteristics as the array prepared catalysts. The reducing strength of

NaBH4, which enables incorporation of metal ions with a wide variety of redox

potentials, is also responsible for the inability of NaBH4 to prepare high surfacearea catalysts. NaBH4 has a sintering effect, precluding preparation of nanostruc-

tured catalysts (A.S. Arico, private communication). Surface areas greater than

30 m2 g1 could not be prepared by borohydride reduction. Attempts to scale up

the method for preparation of bulk catalysts were met with difficulty. In some

cases, even with optimized reaction conditions, the borohydride method yielded

actual bulk compositions that were quite different from the nominal compositions.

In contrast, the Watanabe et al. method (41, 43) yields >80 m2 g1 nanostructured

catalysts. This method involves the oxidation of the sulfite complex of Pt to PtO2,

mixing with RuCl3 to form a mixed Pt/Ru colloid, and reduction with hydrogen togive a highly active PtRu catalyst. Unfortunately, the pH conditions required for

the Watanabe method preclude the inclusion of many other elements (Os, Mo, W,

and others) owing to incompatible Pourbaix boundaries. Other array preparative

methods include electrodeposition (12, 64, 65) and sputter deposition (74, 75). It

remains to be seen whether array preparative methods developed to accommodate

high throughput screening methods are capable of yielding competitive catalysts.

The best methods for catalyst preparation remain to be the highly optimized sin-

gle beaker methods. It is likely that the ideal high throughput preparative method

will be the adaptation of these laborious, but effective, methods to process controlrobotics. Withan et al. have investigated the use of sputter deposition to modify

MEA catalytic layers (75). If sputtering upon catalyzed GDL surfaces proves to

be effective, it opens a wide window for combinatorial studies.

COMBINATORIAL DISCOVERIES OF FUELCELL

ELECTROCATALYSTS

Direct Methanol Fuel Cell AnodesReddington et al. examined combinations of Pt, Ru, Os, Ir, and Rh in quaternary

-

8/7/2019 13818976 New Electrocatalysts by Rial

15/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

16/29

572 SMOTKIN DIAZ-MORALES

Cathodes for PEM Hydrogen/Air Fuel Cells

Recent combinatorial studies employed thin film catalyst libraries made by sputter

deposition of the elements (74). Active Pt-Fe binary and Pt-Co-Cr ternary compo-

sitions were found, as anticipated from earlier work on high surface area catalysts.

Other active catalysts with apparent activities higher than that of Pt-Co-Cr were

also found in the screening experiments, but their compositions have not yet been

disclosed. A representative ternary, Pt50Co25Cr25, was synthesized in scaled-up

form as a carbon-supported catalyst and was tested by rotating disk voltammetry.

A Tafel analysis of these electrodes was informative. Pure Pt/C gave a reduced

Tafel slope at high potentials, whereas the carbon-supported alloy maintained a

slope of 120 mV/decade. The reduced Tafel slope has previously been identified

with the formation of an oxide film on Pt (78).

CLOSING THE LOOP ON DISCOVERYFOCUS TESTING

AND CHARACTERIZATION

Phase Identification and Structural Characterization

Pt-Ru anode catalysts provide a good example of the complexity of phase behav-

ior found with fuel cell catalysts. Ley et al. reported that the lattice parameters

(fcc) of high surface area mixed metal catalysts containing Ru had higher latticeparameters than those observed with arc-melted alloys of the same composition

(54, 55). This results from phasing out some of the smaller Ru atoms from the alloy

phase, leaving a Pt-rich alloy with a correspondingly larger lattice parameter (67).

Figure 11 compares lattice parameters of the fcc phase for high surface area cat-

alysts to those of arc-melted alloys prepared by Ley et al. (67). Gasteiger et al.

reported 10% Ru as optimum at room temperature and about 33% Ru at 60C

on arc-melted alloy surfaces (79). Arico reported 50% Ru as optimal on high

surface area catalysts (although at 130C) (80). Chu & Gilman reported 50%

Ru as optimum on high surface area catalysts at room temperature (63). Theseseemingly controversial reports can be reconciled by examination of the lattice

parameter data. The arc-melted materials are single-phase disordered fcc ther-

modynamic materials with lattice parameter variations that obey Vegards law.

The high surface area catalysts were prepared by kinetically controlled synthetic

methods where uncontrolled phase segregation occurs. All of the high surface

area catalysts of the Ley (and later Gurau) studies were prepared by borohydride

reduction and had only fcc lattice XRD patterns. Gurau confirmed that the high

lattice parameters resulted from incomplete incorporation of the Ru into the fcc

lattice. Thus, if it is the fcc alloy phase that supports the catalytic surface, thena correlation can be drawn between the lattice parameter of the alloy phase of

-

8/7/2019 13818976 New Electrocatalysts by Rial

17/29

COMBINATORIAL ELECTROCATALYSTS 573

Figure 11 Fcc lattice spacings of catalysts and arc-melted alloys. [Reprinted

with permission from (67). Copyright 1998 American Chemical Society]

80%. This qualitatively explains the discrepancy between the optimum for high

surface area catalysts and the optimums reported by Gasteiger for single-phase

alloys. Long and coworkers report that in DMFCs, the active electrocatalyst for

methanol oxidation is not a bimetallic alloy but a mixed phase containing Pt metal

and hydrous ruthenium oxides (RuOxHy) (53). OGrady et al. (81) studied the

structure of Pt-Ru catalysts using X-ray absorption and concluded that in the po-

tential window where methanol oxidation occurs, the metal oxides were reducedto their metallic form. Similarly, in a series of recent work by Russells group

using in situ EXAFS they conclude that for a well-mixed Pt-Ru/C electrocatalyst

the Pt and Ru are both metallic in nature, and exist as a bimetallic alloy (82, 83).

An unsupported PtRuOxcatalyst has been commercialized by E-TEK for DMFC

anodes.

In situ fuel cell spectroscopic and electrochemical studies are ideal for study

of fuel cell catalysts in the most realistic environment. Dinh et al. demonstrated

in situ fuel cell CO stripping voltammetry as a methodology for the characteri-

zation of the catalysts/solid polymer electrolyte interface (84). They were able tocalculate the active area, intrinsic catalytic activity, and, in some cases, the surface

-

8/7/2019 13818976 New Electrocatalysts by Rial

18/29

574 SMOTKIN DIAZ-MORALES

anions are eliminated. In addition to CO2, methylformate and formaldehyde were

observed as products in the methanol vapor fuel cell. Also, Liu demonstrated that

the catalyst Nafion-coating affects anode kinetics in DMFCs (56). Sanicharane

integrated on MEA-surface FTIR studies with exhaust transmission spectroscopyto differentiate between adsorbed species and exhaust species in proximity to the

surface. Viswananthan et al. demonstrated the first X-ray absorption near edge

structure (XANES) spectroscopy on a high performance reformate-air fuel cell to

study the structure of carbon-supported Pt-Ru anode electrocatalysts (66). The fuel

cell was operated in a normal mode without the use of supplemental electrolytes.

The in situ Pt LIII-edge and Ru K-edge XANES of the fuel cell MEAs showed

metallic characteristics under all operating conditions. It is not unexpected that

hydrogen fuel cell anode catalysts are metallic because the polarization of anode

catalysts is typically less than 100 mV.The important lesson for combinatorial analysis in this case is that phase identi-

fication is not a trivial issue because the best catalysts may consist of several phases

(in addition to the support). Which phases are present depends on the method of

preparation, as well as on the electrochemical history of the catalyst. There clearly

exists a need for high throughput structural characterization techniques that could

complement the fast synthesis/screening methods that have been reported to date

for electrochemical arrays. Ideally, one could obtain phase maps and correlate

them with activity maps as a function of composition and preparative conditions.

Refining Heuristic Models

Recently, concentration-dependent current-voltage curves, together with CD3OH

and CH3OD kinetic data, have shown unambiguously that CH bond activation be-

comes a kinetically comparable effect within the fuel cell relevant potential regime

for two high-performance mixed metal catalysts (PtRu and PtRuOsIr) (32). At po-

tentials above 0.4 V, CH activation becomes the dominant barrier to methanol

oxidation. This result could be of practical importance because anode potentials

between 0.4 and 0.5 V versus a dynamic hydrogen electrode (DHE) will be well

within DMFC operating potentials window when low crossover membranes are

developed. The inclusion of CH bond activation as a possible rate-determining

step also has implications for future catalyst discovery, since it suggests an ex-

pansion of the composition space to include CH activator elements. Figure 12

is a Ley diagram that has been modified to include CH activators. Interestingly,

Figures 2 and 12 suggest that Os can serve both as a CH activator as well as a

water activator, which is consistent with DFT calculations of Kua & Goddard (89).

CONCLUSIONS AND OUTLOOK

-

8/7/2019 13818976 New Electrocatalysts by Rial

19/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

20/29

576 SMOTKIN DIAZ-MORALES

(e.g., hundreds over a year rather than tens of thousands). Focus level screening

should be coupled to high throughput fundamental science. Design of experiment

strategies must leverage acquired data with advanced informatics to increase the

probability of successful discoveries.There is an opportunity for high throughput electrochemical methods to advance

our understanding of which phase or phases are important to the catalyzed reactions

and what role metal components play in those phases. The finding of Reddington

et al. (8) that Ir substantially improves the performance of PtRuOs as a DMFC

anode evoked work by Lei et al. (32) to study CH activation. Serendipitous finding

can force one to re-examine mechanistic models.

The screening bottleneck has been removed. We now require scalable high

throughput synthetic methods yielding bulk catalysts that can be compared head

to head against state-of-the-art catalysts. The black magic associated with kinet-ically controlled catalyst preparative methods must be removed by careful design

of experiment strategies to identify and understand all of the factors involved in

synthetic methods. This suggests the need for precise process control robotics in

the development of high throughput synthetic methods.

ACKNOWLEDGMENTS

This work was supported by grants from theArmy Research Office (grant DAAH04-

94-G-0055), the Army Research Laboratory, Collaborative Technology Alliancein Power and Energy, NuVant Systems Inc., and the University of Puerto Rico at

Rio Piedras.

The Annual Review of Materials Research is online at

http://matsci.annualreviews.org

LITERATURECITED

1. Mittasch A. 1950. Adv. Catal. 2:811042. Hanak J. 1970. J. Mater. Sci. 5:96471

3. Nayar A, Liu R, Allen RJ, McCall MJ,

Willis RR, Smotkin ES. 2002. Anal.

Chem. 74:193338

4. Holzwarth A, Schmidt H-W, Maier WF.

1998. Angew. Chem. Int. Ed. 37:264447

5. Cong P, Doolen RD, Fan Q, Giaquinta

DM, Guan S, et al. 1999. Angew. Chem.

Int. Ed. 38:48388

6. Orschel M, Klein J, Schmidt H-W,

Maier WF. 1999. Angew. Chem. Int. Ed.

8. Reddington E, Sapienza A, Gurau B,Viswanathan R, Sarangapani S, et al.

1998. Science 280:173537

9. Liu R, Smotkin ES. 2002. J. Electroanal.

Chem. 535:4955

10. Sullivan MG, Utomo H, Fagan PJ, Ward

MD. 1999. Anal. Chem. 71:436975

11. Jiang R, Chu D. 2002. J. Electroanal.

Chem. 527:13742

12. Warren CJ, Haushalter RC, Matsiev L.

2001. U.S. Patent No. 6187164

13. Pope J, Buttry D. 2000. World Patent Appl.

-

8/7/2019 13818976 New Electrocatalysts by Rial

21/29

COMBINATORIAL ELECTROCATALYSTS 577

15. Senkan S. 2001. Angew. Chem. Int. Ed.

40:31229

16. Mallouk TE, Smotkin ES. 2003. Combi-

natorial catalyst development methods. In

Handbook of Fuel CellsFundamentals,

Technology and Applications, Electro-

catalysis, ed. W Vielstich, H Gasteiger, A

Lamm, 2:33447. London: Wiley & Sons

17. Arico AS, Srinivasan S, Antonucci V.

2001. Fuel Cells 1:13361

18. Gottesfeld S, Zawodzinski TA. 1997.

Polymer Electrolyte Fuel Cells. In Ad-

vances in Electrochemical Science and

Engineering, ed. RC Alkire, H Gerischer,DM Kolb, CW Tobias, 5:195301. Wein-

heim: Wiley-VCH

19. Wilson MS, Gottesfeld S. 1992. J. Appl.

Electrochem. 22:17

20. Gottesfeld S, Pafford J. 1988. J. Elec-

trochem. Soc. 135:265152

21. Thirumalai D, Zawodzinski TA, Springer

TE, Gottesfeld S. 1997.Electrochem. Soc.

Meet. 97(1): (Abstr.)

22. Markovic NM, Ross PN Jr. 2002. Surf. Sci.Rep. 45:117229

23. Appleby AJ. 1986. Energy 11:13

24. Mukerjee S, Srinivasan S. 1993. J. Elec-

troanal. Chem. 357:20124

25. Mukerjee S, Srinivasan S, Soriaga MP,

McBreen J. 1995. J. Electrochem. Soc.

142:140923

25a. Toda T, Igarashi H, Uchida H, Watanabe

M. 1999. J. Electrochem. Soc. 146:3750

5626. Min M-k, Cho J, Cho K, Kim H. 2000.

Electrochim. Acta 45:421117

27. Liu L, Pu C, Viswanathan R, Fan Q, Liu

R, Smotkin ES. 1998. Electrochim. Acta

43:365763

28. Beden B, Leger J-M, Lamy C. 1992.

Electrocatalytic oxidation of oxygenated

aliphatic organiccompounds at noble met-

als electrodes. InModern Aspects of Elec-

trochemistry, ed. JOM Bockris, BE Con-

way, RE White, 22:97247. New York:

30. Chrzanowski W, Herrero E, Wieckowski

A. 1995.Ext. Abst. 187th Soc. Meet. Reno,

95:753. Pennington, NJ: Electrochem.

Soc.

31. Herrero E, Chrzanowski W, Wieckowski

A. 1995. J. Phys. Chem. 99:1042324

32. Lei H-W, Suh S, Gurau B, Workie B,

Smotkin ES. 2002. Electrochim. Acta 47:

291319

33. Alonso-Vante N, Tributsch H. 1986. Na-

ture 323:43132

34. Alonso-Vante N, Tributsch H, Solorza-

Feria O. 1995. Electrochim. Acta 40:567

7635. Bockris JOM, Wroblowa H. 1964.J. Elec-

troanal. Chem. 7:42851

36. Dahms H, Bockris JOM. 1964. J. Elec-

trochem. Soc. 111:72836

37. Janssen MMP, Moolhuysen J. 1976. Elec-

trochim. Acta 21:86978

38. Adzic RR, OGrady WE, Srinivasan S.

1981. J. Electrochem. Soc. 128:1913

19

39. Kadirgan F, Beden B, Leger J-M, Lamy C.1981. J. Electroanal. Chem. 125:89103

40. Lamy C. 1984. Electrochim. Acta

29:158188

41. Watanabe M, Furuuchi Y, Motoo S. 1985.

J. Electroanal. Chem. 191:36775

42. Shibata M, Motoo S. 1986.J. Electroanal.

Chem. 209:15118

43. Watanabe M, Uchida M, Motoo S. 1987.

J. Electroanal. Chem. 229:395406

44. Szabo S, Bakos I. 1987. J. Electroanal.Chem. 230:23340

45. Gasteiger HA, Markovic NM, Ross PN Jr,

Cairns EJ. 1994. J. Phys. Chem. 98:617

25

46. Markovic NM, Gasteiger HA, Ross PN

Jr, Jiang X, Villegas I, Weaver MJ. 1995.

Electrochim. Acta 40:9198

47. Parsons R, VanderNoot T. 1988. J. Elec-

troanal. Chem. 257:945

48. Frelink T, Visscher W, Cox AP, van Veen

JAR. 1995.Electrochim. Acta 40:153743

-

8/7/2019 13818976 New Electrocatalysts by Rial

22/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

23/29

COMBINATORIAL ELECTROCATALYSTS 579

82. Lampitt RA, Carrette LPL, Hogarth MP,

Russell AE. 1999. J. Electroanal. Chem.

460:8087

83. Maniguet S, Mathew RJ, Russell AE.

2000. J. Phys. Chem. B 104:19982004

84. Dinh HN, Ren X, Garzon F, Zelenay P,

Gottesfeld S. 2000. J. Electroanal. Chem.

491:22233

85. Fan Q, Pu C, Ley KL, Smotkin ES. 1996.

J. Electrochem. Soc. 143: L2123

86. Fan Q, Pu C, Smotkin ES. 1996. J. Elec-

trochem. Soc. 143:305357

87. Sanicharane S, Bo A, Sompalli B, Gurau

B, Smotkin ES. 2002.J. Electrochem. Soc.

149: A55457

88. Bo A, Sanicharane S, Sompalli B, Fan Q,

Gurau B, et al. 2000. J. Phys. Chem. B

104:737781

89. Kua J, Goddard WA III. 1999. J. Am.

Chem. Soc. 121:1092841

-

8/7/2019 13818976 New Electrocatalysts by Rial

24/29

Figure 4 (a) An array of 28 Pt-Rh-Os catalyst spots in 6 M aqueous methanol,

pH 6, quinine indicator. (Left) Image in white light. (Center) Fluorescence image at

low overpotential. (Right) Fluorescence image at high overpotential, where methanol

oxidation occurs at every spot in the array. [Reprinted with permission from Science.

Copyright 1998 Am. Assoc. Adv. Sci. (8).] (b) (Left) Robotic delivery of metal salt

solutions to a 715-well pentanary array. A Toray paper carbon sheet is sandwiched

between flexible gaskets (red), which define the wells. (Right) Top view of a screeningcell for 715-member electrode arrays. [Reprinted with permission from (16) Copyright

2003 J h Wil & S ] ( ) A t A ti i id tifi d d

-

8/7/2019 13818976 New Electrocatalysts by Rial

25/29

Figure 7 Component of array fuel cell. (Center) Array flow field, Clockwise fromupper right: array MEA, graphite flow field sensor, counter electrode flow field, as-

sembled cell with multielectrode potentiostat. Provided by NuVant Systems, Inc.,

Chicago, IL.

-

8/7/2019 13818976 New Electrocatalysts by Rial

26/29

Figure 8 (Top) Mass transport corrected IV curves for control experiment array.

(Bottom) IV curves for the ranking of four catalyst, PtRu (Johnson Matthey), PtRu

(reduce by NaBH4), PtRu oxide (E-TEK), and Pt (Johnson Matthey) in DMFC anode

operating region. [Reprinted with permission from (91). Copyright 2002 Elsevier.]

-

8/7/2019 13818976 New Electrocatalysts by Rial

27/29

Figure 10 PtRuOsIr composition map, looking through the PtRuOs ternary

face. Increasing IR concentration is shown in gray scale. Black dots on the PtRu and

PtOs axes shows the binary solubility limits, and the ternary region is approximatelydefined by the area above the dashed line joining these binary limits. Anode catalyst

composition are indicated by open circles, and the region of highest catalytic activity

is shown as a circle containing the best catalyst found by combinatorial screening,

PT44Ru41Os10Ir5 (). [Reprinted with permission from (67) Copyright 1998 American

Chemical Society.]

-

8/7/2019 13818976 New Electrocatalysts by Rial

28/29

-

8/7/2019 13818976 New Electrocatalysts by Rial

29/29