136673973 110KV SagTension Calculation 1

-

Upload

atef-ben-ammar -

Category

Documents

-

view

221 -

download

0

Transcript of 136673973 110KV SagTension Calculation 1

-

7/28/2019 136673973 110KV SagTension Calculation 1

1/13

1.0 SYSTEM PARAMETERS

1.1 System Voltage V : 138 kV

1.2 Frequency f : 60 Hz

2.0 ENVIRONMENTAL DETAILS

2.1 Wind Pressure on Conductor & Ground Wire wpc : 47 kg/m2(Table-2, IS-802-1977 - Part-II)

2.2 Wind Pressure on Towers wpt : 195 kg/m2(Table-1, IS-802-1977 - Part-II)

2.3 Average absolute Temperature of air Ta : 32 oC(IS-802-1977 - Part-II)

2.4 Maximum Temperature Tmax : 75 oC(Refer note below)

2.5 Minimum Temperature Tmin : 0 oC(Refer note below)

3.0 LAYOUT DETAILS

3.1 Distance between supports (Maximum span) L : 250 m(Maximum Span )

3.2 Height of conductor above earth at Left end hl : 9.5 m

3.3 Height of conductor above earth at Right end hr : 13 m

3.4 Phase to Phase spacing of conductor a : 2.80 m

3.5 Width of Girder Wg : 0.75 m

(Assumed )3.6 Initial Tensile Force per conductor per phase Z0 : 1200 kg(Assumed)

Note on Max & Min Temperature - IS -802-1977 (Part-II) Cl 4.1

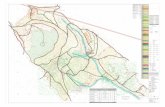

'"The temperature varies for different localities under different diurnal & seasonal conditions.The absolutemaximum & minimum temepratures,which may be expected in different localities in the country, are indicatedin maps of India in Fig.2 and Fig.3 respectively. These may be used for assessing temperature stresses inconductors and ground wires. The absolute maximum temperature value given in Fig.2 shall be incresed by17o Cto allow for sun's radiation, heating effect of current,etc, in the conductor"Fig 2 & 3 are enclosed as Annexure-I

4.0 CONDUCTOR DATA

4.1 No.of Conductors n : 1 (Single Wolf)

4.2 Type of conductor : ACSR

4.3 Code name : ZEBRA

4.4 Cross sectional area of conductor As : 0.0004840 cm2

4.5 Overall Diameter ds : 0.02862 m

4.6 Unit weight of conductor ms : 1.623 kg/m (Typical VendorDat

4.7 Modulus of Elasticity of conductor E : 7.03E+09 kg/cm2

4.8 Ultimate Tensile Strength UTS : 13316 kg

4.9 Coefficient of Linear Expansion a l : 1.9E-05 m/deg C

-

7/28/2019 136673973 110KV SagTension Calculation 1

2/13

6.0 INSULATOR & HARDWARE DETAILS

6.1 Number of Discs per String nd : 12

6.2 Length of each Disc ld : 0.145 m

6.3 Mean Diameter of Insulator dd : 0.255 m

6.4 Weight of each Disc wd : 3.6 kg (Typical Vendor

6.5 Length of Hardware lh : 0.600 m

6.6 Weight of Hardware wh : 20 kg

6.7 No of Strings ns : 1 (Single Tensio

7.0 CALCULATION - PRELIMINARY

7.1 Length of Insulator String li = 12*0.145+0.6

= 2.34 m

7.2 Cord length of main conductor in the span Lc = L -(2li + Wg)

= #NAME?

= #NAME? m7.3 Effective Span

Le = L-Wg

= #NAME? m

7.4 No.of Spacers in the given Span Ns = Lc/ls

= 0

7.5 Weight of Total Spacer in a Span Nst = Ns * Ws

= 0 * 0

= 0 kg

7.6 Spacer Weight / Conductor Length Nsu = Nst/Lc/n

= #NAME?

= #NAME? Kg/m

7.7 Equivalent Conductor Weight m's = ms + Nsu

= #NAME?

= #NAME? kg/m

7.8 Weight of One Insulator & Hardware Unit per wu = (ns * nd * wd + wh)/nConductor

= (1 * 12 * 3.6 + 20 ) / 1

= 63.2 kg

8.0 SAG TENSION CALCULATION

8.1METHODOLOGY AND ASSUMPTIONS

To Calculate the Sag-Tension of the Given Span in accordance with the following standards/methodology:-a) IS:802 1995(Part 1) 2nd Rev "Code of practice for use of structural steel in overhead transmission

-

7/28/2019 136673973 110KV SagTension Calculation 1

3/13

9.3 Constant (G1) = w1 2 *(lc/2)2*E6*As2

9.4 Constant (F1) = f1 - w1 2 *(lc/2) 2 *E - (T - Tmin)*E*a6*T2

9.5 Stress(f2)

Stress f2 can be found out by solving the following cubic equation package

gs(f2) = f23 F1 * f22 - G1 = 0

9.6 Constant (a1) for conductor catenary = T / w1

9.7 Constant (a2) for Insulator catenary = T (Wu/li) + (1/2 * Wpt *dd* %Wind))

9.8 Assumed Half inclined length of conductor Span = Xass

9.9 Projected length of insulator catenary arc (X1) = a2*Xass/a1

9.10 Arc from insulator catenary centre to = a2*Sinh(X1/a2)end of string(SP)

9.11 Total arc length (RSP) = li+ SP

9.12 Projected length of total Arc (X2) = a2*Sinh-1(RSP/a2)

9.13 Projected length of insulator string (X3) = X2 - X1

9.14 Actual Half inclined length of conductor = Le/2 - X3Span (Xact)

Difference between Xass & Xact Should be zeroi.e, Xass - Xact = 0

9.15 Sag at centre of Insulator catenary, = a2*(Cosh(X1/a2) - 1)below string end (D1)

9.16 Sag at centre of Insulator catenary, = a2*(Cosh(X2/a2) - 1)below support (D2)

9.17 Conductor Sag below end of = a1*(Cosh(X/a1) - 1)insulator string (D3)

9.18 Sag along Incline (S) = D3 + D2 - D1

9.19 Vertical Sag = S * cos(tan-1(% wind * Wpc*ds/m's)

9.20 Factor of Safety (Actual) = UTS/T

-

7/28/2019 136673973 110KV SagTension Calculation 1

4/13

10.0 RESULTS

#NAME?

Constant

( F 1 )

#NAME? #NAME?

#NAME?

Constant

( G 1 )

#NAME?

32 0

#NAME?

Temp

( 0C )

Wind

( % )

Intialtension( kg )

32 100 986

49.00

0 36 1000

EquivalentWeight of

Conductor ( W 1 )

#NAME?

SP RSP

Stress

( f 2 )

512.990#NAME?

0 36

#NAME?

#NAME? #NAME? #NAME?#NAME?

#NAME?75 0

Temp( 0C )

Wind( % )

773

#NAME?

#NAME?

#NAME? 32.725

136.613#NAME?

#NAME?#NAME?

X2 X3

112.215

75 0

Stress at Initialtemperature

( f 1 )

2066115.702

512.990

136.613

968.000

49.00 #NAME?

32

Xass X1

100

32 0

49.00 #NAME?

638

#NAME? #NAME? #NAME?

49.00 #NAME? #NAME? #NAME? #NAME? #NAME?

#NAME?

#NAME?

0 36 #NAME? #NAME? #NAME?

Temp( 0C )

Wind( % )

D1 D2 D3 Sag Along InclineFOS

Actual

#NAME?

#NAME? #NAME? 13.316

#NAME?

Vertical Sag

32 0 #NAME? #NAME? #NAME?

32 100 #NAME? #NAME? #NAME? 13.500

#NAME? #NAME? 17.235

#NAME? #NAME? #NAME? 20.87175 0 #NAME? #NAME?

5 0 #NAME? #NAME?136.613 #NAME?

-

7/28/2019 136673973 110KV SagTension Calculation 1

5/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

6/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

7/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

8/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

9/13

a2

35.14568

1

ME?

23.62215

26.86861

28.60613

ME?

ME?

ME?

Xact

ME?

ME?

ME?

ME?

ult

fe

fe

fe

fe

-

7/28/2019 136673973 110KV SagTension Calculation 1

10/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

11/13

0.6*(2) 17 *(2) x

40 deg

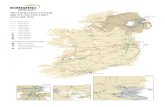

1 LADY BIRD 25 42.33 0.6721 1782 ANT 30 52.26 0.5444 2043 FLY 40 62.86 0.4526 2294 BLUE BOTTLE 45 72.84 0.3906 2525 EARWIG 48 77.7 0.3662 2646 GRASS HOPPER 50 83.13 0.3422 2757 CLEGG 60 94.56 0.3009 2988 WASP 65 104.8 0.2715 3189 CATERPILLAR 110 183 0.1555 460

10 CHAFER 130 209.9 0.1356 50411 SPIDER 140 233.8 0.1217 54012 COCKROACH 160 261.5 0.1088 575

13 BUTTERFLY 185 317.5 0.08959 65514 MOTH 225 367.2 0.07749 72015 LOCUST 260 421.9 0.06743 79016 MAYBUG 300 473.6 0.05982 85017 SCORPION 325 518.4 0.05488 895

Cu1 303 0.0611 86018 SQUIRRIEL 13 20.71 1.374 11519 GOPHER 16 25.91 1.098 13320 WEASEL 20 31.21 0.9116 15021 FOX 22 36.21 0.7857 16522 FERRET 25 41.87 0.6795 18123 RABBIT 30 52.21 0.5449 20824 MINK 40 62.32 0.4565 23425 BEAVER 45 74.07 0.3841 26126 RACCOON 48 77.83 0.3656 27027 OTTER 50 82.85 0.3434 28128 CAT 55 94.21 0.302 30529 DOG 65 103.6 0.2745 32430 LEOPARD 80 129.7 0.2193 37531 COYOTE 80 128.5 0.2214 37532 TIGER 80 128.1 0.2221 38233 WOLF 95 154.3 0.1844 43034 LYNX 110 179 0.1589 47535 PANTHER 130 207 0.1375 52036 LION 140 232.5 0.1223 55537 BEAR 160 258.1 0.1102 59538 GOAT 185 316.5 0.08989 680

39 SHEEP 225 366.1 0.07771 74540 DEER 260 419.3 0.06736 80641 ELX 300 465.7 0.0611 86042 MOOSE 325 515.7 0.05517 90043 ZEBRA 260 418.6 0.068 795

SI.NoRated C

Code WordCopper Area

(sq.mm)

Aluminium Area

(Sq.mm)

Resistance at20 deg

(ohms/km)

-

7/28/2019 136673973 110KV SagTension Calculation 1

12/13

-

7/28/2019 136673973 110KV SagTension Calculation 1

13/13