11488 VALIDAPRO 400L

-

Upload

grincheu70 -

Category

Documents

-

view

229 -

download

0

description

Transcript of 11488 VALIDAPRO 400L

Codeware, Inc.

Sarasota, FL, USA

www.codeware.com

COMPRESS Pressure Vessel Design Calculations

Item: Split Stream Dearator

Vessel No: V-1234

Customer: Magaladon Oil Venture

Contract: C-45490-R56

Designer: John Doe

Date: April 1, 2001

You can edit this page by selecting Cover Page settings... in the report menu.

Table of ContentsGeneral Arrangement Drawing................................................................................................................................1/46

Deficiencies Summary..............................................................................................................................................2/46

Pressure Summary...................................................................................................................................................3/46

Revision History........................................................................................................................................................4/46

Settings Summary.....................................................................................................................................................5/46

Radiography Summary.............................................................................................................................................7/46

Thickness Summary.................................................................................................................................................8/46

Weight Summary.......................................................................................................................................................9/46

Long Seam Summary.............................................................................................................................................10/46

Hydrostatic Test......................................................................................................................................................12/46

Liquid Level bounded by Bottom of vessel..........................................................................................................13/46

F&D Head #1............................................................................................................................................................14/46

Straight Flange on F&D Head #1............................................................................................................................16/46

Cylinder #1...............................................................................................................................................................22/46

Legs #1.....................................................................................................................................................................31/46

Transition #1............................................................................................................................................................37/46

i

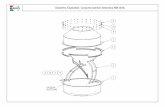

General Arrangement Drawing

1/46

Deficiencies Summary

Deficiencies for Transition #1Transition calculations cannot be completed until a component is attached to the small end of the cone (or thediscontinuity is eliminated).The half apex angle is greater than 30 degrees. This results in UW-3 Category B weld joints being UW-12 type 8. Auser defined joint efficiency should be used.

Warnings Summary

Warnings for VesselThe vessel does not have a bottom closure (head or cover). (warning)

2/46

Pressure Summary

Component Summary

IdentifierP

Design(psi)

T

Design(°F)

MAWP(psi)

MAP(psi)

MDMT(°F)

MDMTExemption

ImpactTested

F&D Head #1 0,01 120 29,4 29,57 -320 Note 1 No

Straight Flange on F&D Head #1 0,01 120 51,86 52,05 -320 Note 2 No

Cylinder #1 0,01 120 50,35 52,05 -320 Note 3 No

Transition #1 0,01 120 23,83 25,6 -320 Note 4 No

Legs #1 0,01 120 0,01 N/A N/A N/A N/A

Chamber Summary

Design MDMT -20 °F

Rated MDMT -320 °F @ 0,01 psi

MAWP hot & corroded 0,01 psi @ 120 °F

MAP cold & new 25,6 psi @ 70 °F

(1) This pressure chamber is not designed forexternal pressure.

Notes for MDMT Rating

Note # Exemption Details

1. Impact test exempt per UHA-51(g) (coincident ratio = 0,0028)

2. Impact test exempt per UHA-51(g) (coincident ratio = 0,0031)

3. Impact test exempt per UHA-51(g) (coincident ratio = 0,0262)

4. Impact test exempt per UHA-51(g) (coincident ratio = 0,0582)

3/46

Revision History

Revisions

No. Date Operator Notes

0 10/29/2015 mnmeil New vessel created ASME Section VIII Division 1 [COMPRESS 2015 Build 7500]

4/46

Settings Summary

COMPRESS 2015 Build 7500

ASME Section VIII Division 1, 2013 Edition

Units U.S. Customary

Datum Line Location 0,00" from bottom seam

Vessel Design Mode Get Thickness from Pressure

Minimum thickness 0,0625" per UG-16(b)

Design for cold shut down only No

Design for lethal service (full radiography required) No

Design nozzles for Design P, find nozzle MAWP andMAP

Corrosion weight loss 100% of theoretical loss

UG-23 Stress Increase 1,20

Skirt/legs stress increase 1,0

Minimum nozzle projection 6"

Juncture calculations for α > 30 only Yes

Preheat P-No 1 Materials > 1,25" and <= 1,50" thick No

UG-37(a) shell tr calculation considers longitudinal stress No

Cylindrical shells made from pipe are entered as minimum thickness No

Nozzles made from pipe are entered as minimum thickness No

Pipe caps are entered as minimum thickness No

Butt welds Tapered per Figure UCS-66.3(a)

Disallow Appendix 1-5, 1-8 calculations under 15 psi No

Hydro/Pneumatic Test

Shop Hydrotest Pressure 1,3 times vessel MAWP

Test liquid specific gravity 1,00

Maximum stress during test 90% of yield

Required Marking - UG-116

UG-116(e) Radiography None

UG-116(f) Postweld heat treatment None

Code Cases\Interpretations

Use Code Case 2547 No

Use Code Case 2695 No

Apply interpretation VIII-1-83-66 Yes

Apply interpretation VIII-1-86-175 Yes

5/46

Apply interpretation VIII-1-01-37 Yes

Apply interpretation VIII-1-01-150 Yes

Apply interpretation VIII-1-07-50 Yes

No UCS-66.1 MDMT reduction No

No UCS-68(c) MDMT reduction No

Disallow UG-20(f) exemptions No

UG-22 Loadings

UG-22(a) Internal or External Design Pressure Yes

UG-22(b) Weight of the vessel and normal contents under operating or testconditions Yes

UG-22(c) Superimposed static reactions from weight of attached equipment(external loads) No

UG-22(d)(2) Vessel supports such as lugs, rings, skirts, saddles and legs Yes

UG-22(f) Wind reactions No

UG-22(f) Seismic reactions No

UG-22(j) Test pressure and coincident static head acting during the test: No

Note: UG-22(b),(c) and (f) loads only considered when supports are present.

6/46

Radiography Summary

UG-116 Radiography

ComponentLongitudinal Seam Top Circumferential Seam Bottom Circumferential Seam

MarkCategory

(Fig UW-3) Radiography / Joint Type Category(Fig UW-3) Radiography / Joint Type Category

(Fig UW-3) Radiography / Joint Type

F&D Head #1 A None UW-11(c) / Type 1 N/A N/A B None UW-11(c) / Type 1 None

Cylinder #1 A None UW-11(c) / Type 1 B None UW-11(c) / Type 1 B None UW-11(c) / Type 1 None

Transition #1 A None UW-11(c) / Type 1 B None UW-11(c) / Type 1 B N/A / Type 8 None

UG-116(e) Required Marking: None

7/46

Thickness Summary

Component Data

ComponentIdentifier

Material Diameter(in)

Length(in)

Nominal t(in)

Design t(in)

Total Corrosion(in)

JointE

Load

F&D Head #1 SA-240 316L 28 ID 4,816 0,0625* 0,0004 0 0,70 Internal

Straight Flange on F&D Head #1 SA-240 316L 28 ID 0,5 0,0625 0,0003 0 0,70 Internal

Cylinder #1 SA-240 316L 28 ID 41,75 0,0625 0,0021 0 0,70 Internal

Transition #1 SA-240 316L 1,5 / 28 ID 8 0,0625 0,0043 0 0,70 Internal

Knuckle of Transition #1 SA-240 316L 28 -- 0,0625 0,0036 0 -- Internal

*Head minimum thickness after forming

Definitions

Nominal t Vessel wall nominal thickness

Design t Required vessel thickness due to governing loading + corrosion

Joint E Longitudinal seam joint efficiency

Load

Internal Circumferential stress due to internal pressure governs

External External pressure governs

Wind Combined longitudinal stress of pressure + weight + windgoverns

Seismic Combined longitudinal stress of pressure + weight + seismicgoverns

8/46

Weight Summary

Weight (lb) Contributed by Vessel Elements

Component MetalNew*

MetalCorroded Insulation Insulation

Supports Lining Piping+ Liquid

Operating Liquid Test Liquid Surface Areaft2New Corroded New Corroded

F&D Head #1 14,1 14,1 0 0 0 0 75,6 75,6 75,6 75,6 6

Cylinder #1 66,7 66,7 0 0 0 0 928 928 928 928 26

Transition #1 14,2 14,2 0 0 0 0 80,9 80,9 80,9 80,9 5

Legs #1 97,7 97,7 0 0 0 0 0 0 0 0 12

TOTAL: 192,7 192,7 0 0 0 0 1 084,4 1 084,4 1 084,4 1 084,4 48

*Shells with attached nozzles have weight reduced by material cut out for opening.

Weight (lb) Contributed by Attachments

Component Body Flanges Nozzles &Flanges Packed

BedsLadders &Platforms

Trays TraySupports

Rings &Clips

VerticalLoads

Surface Areaft2

New Corroded New Corroded

F&D Head #1 0 0 0 0 0 0 0 0 0 0 0

Cylinder #1 0 0 0 0 0 0 0 0 0 0 0

Transition #1 0 0 0 0 0 0 0 0 0 0 0

Legs #1 0 0 0 0 0 0 0 0 0 0 0

TOTAL: 0 0 0 0 0 0 0 0 0 0 0

Vessel Totals

New Corroded

Operating Weight (lb) 1 277 1 277

Empty Weight (lb) 193 193

Test Weight (lb) 1 277 1 277

Surface Area (ft2) 48 -

Capacity** (US gal) 130 130

**The vessel capacity does not includevolume of nozzle, piping or otherattachments.

Vessel Lift Condition

Vessel Lift Weight, New (lb) 193

Center of Gravity from Datum (in) 10,1934

9/46

Long Seam Summary

Shell Long SeamAngles

Component Seam 1

Cylinder #1 0°

Transition #1 30°

Shell Plate Lengths

Component StartingAngle Plate 1

Cylinder #1 0° 88,1609"

Transition #1 30° 88,1609"

Notes

1) Plate Lengths use the circumference of the vessel based on the mid diameter of the components.2) North is located at 0°

10/46

Shell Rollout

11/46

Hydrostatic Test

Horizontal shop hydrostatic test based on MAWP per UG-99(b)

Gauge pressure at 70°F =1,3*MAWP*LSR= 1,3*0,01*1= 0,01 psi

Horizontal shop hydrostatic test

IdentifierLocal testpressure

(psi)

Test liquidstatic head

(psi)

UG-99(b)stressratio

UG-99(b)pressure

factor

F&D Head #1 (1) 1,024 1,011 1 1,30

Straight Flange on F&D Head #1 1,024 1,011 1 1,30

Cylinder #1 1,024 1,011 1 1,30

Transition #1 1,024 1,011 1 1,30

(1) F&D Head #1 limits the UG-99(b) stress ratio.(2) The zero degree angular position is assumed to be up, and the testliquid height is assumed to the top-most flange.

The field test condition has not been investigated.

12/46

Liquid Level bounded by Bottom of vessel

ASME Section VIII Division 1, 2013 Edition

Location from Datum (in) 55,0035

Operating Liquid Specific Gravity 1

13/46

F&D Head #1

ASME Section VIII Division 1, 2013 Edition

Component F&D Head

Material SA-240 316L (II-D p. 74, ln. 9)

Attached To Cylinder #1

ImpactTested Normalized Fine Grain

Practice PWHT Optimize MDMT/Find MAWP

No No No No No

DesignPressure (psi)

DesignTemperature (°F)

DesignMDMT (°F)

Internal 0,01 120 -20

Static Liquid Head

Condition Ps (psi) Hs (in) SG

Operating 0,17 4,7535 1

Test horizontal 1,01 28 1

Dimensions

Inner Diameter 28"

Crown Radius L 28"

Knuckle Radius r 1,7"

Minimum Thickness 0,0625"

Corrosion Inner 0"

Outer 0"

Length Lsf 0,5"

Nominal Thickness tsf 0,0625"

Weight and Capacity

Weight (lb)1 Capacity (US gal)1

New 14,12 9,06

Corroded 14,12 9,06

Radiography

Category A joints None UW-11(c) Type 1

Head to shell seam None UW-11(c) Type 11includes straight flange

14/46

Results Summary

Governing condition UG-16

Minimum thickness per UG-16 0,0625" + 0" = 0,0625"

Design thickness due to internal pressure (t) 0,0004"

Maximum allowable working pressure (MAWP) 29,4 psi

Maximum allowable pressure (MAP) 29,57 psi

Rated MDMT -320°F

UHA-51 Material Toughness Requirements

tr = 0,18*28*1 / (2*16 700*0,7 - 0,2*0,18) = 0,0002"

Stress ratio = tr*E* / (tn - c) = 0,0002*0,8 / (0,0625 - 0) = 0,0028

Impact test exempt per UHA-51(g) (coincident ratio = 0,0028)

Rated MDMT = -320°F

Material is exempt from impact testing at the Design MDMT of -20°F.

Factor M

M = 1/4*[3 + (L / r)1/2]

Corroded M = 1/4*[3 + (28 / 1,7)1/2] 1,7646

New M = 1/4*[3 + (28 / 1,7)1/2] 1,7646

Design thickness for internal pressure, (Corroded at 120 °F) Appendix 1-4(d)

t = P*L*M / (2*S*E - 0,2*P) + Corrosion= 0,18*28*1,7646 / (2*16 700*0,7 - 0,2*0,18) + 0= 0,0004"

Maximum allowable working pressure, (Corroded at 120 °F) Appendix 1-4(d)

P = 2*S*E*t / (L*M + 0,2*t) - Ps= 2*16 700*0,7*0,0625 / (28*1,7646 + 0,2*0,0625) - 0,17= 29,4 psi

Maximum allowable pressure, (New at 70 °F) Appendix 1-4(d)

P = 2*S*E*t / (L*M + 0,2*t) - Ps= 2*16 700*0,7*0,0625 / (28*1,7646 + 0,2*0,0625) - 0= 29,57 psi

% Forming strain - UHA-44(a)(2)

EFE = (75*t / Rf)*(1 - Rf / Ro)= (75*0,0625 / 1,7313)*(1 - 1,7313 / infinity)= 2,7076%

15/46

Straight Flange on F&D Head #1

ASME Section VIII Division 1, 2013 Edition

Component Cylinder

Material SA-240 316L (II-D p. 74, ln. 9)

ImpactTested Normalized Fine Grain

Practice PWHT Optimize MDMT/Find MAWP

No No No No No

DesignPressure (psi)

DesignTemperature (°F)

DesignMDMT (°F)

Internal 0,01 120 -20

Static Liquid Head

Condition Ps (psi) Hs (in) SG

Operating 0,19 5,2535 1

Test horizontal 1,01 28 1

Dimensions

Inner Diameter 28"

Length 0,5"

Nominal Thickness 0,0625"

Corrosion Inner 0"

Outer 0"

Weight and Capacity

Weight (lb) Capacity (US gal)

New 0,8 1,33

Corroded 0,8 1,33

Radiography

Longitudinal seam None UW-11(c) Type 1

Bottom Circumferentialseam None UW-11(c) Type 1

16/46

Results Summary

Governing condition UG-16

Minimum thickness per UG-16 0,0625" + 0" = 0,0625"

Design thickness due to internal pressure (t) 0,0003"

Design thickness due to combined loadings + corrosion 0"

Maximum allowable working pressure (MAWP) 51,86 psi

Maximum allowable pressure (MAP) 52,05 psi

Rated MDMT -320 °F

UHA-51 Material Toughness Requirements

tr = 0,2*14 / (16 700*0,7 - 0.6*0,2) = 0,0002"

Stress ratio = tr*E* / (tn - c) = 0,0002*0,8 / (0,0625 - 0) = 0,0031

Impact test exempt per UHA-51(g) (coincident ratio = 0,0031)

Rated MDMT = -320°F

Material is exempt from impact testing at the Design MDMT of -20°F.

Design thickness, (at 120 °F) UG-27(c)(1)

t = P*R / (S*E - 0,60*P) + Corrosion= 0,2*14 / (16 700*0,70 - 0,60*0,2) + 0= 0,0003"

Maximum allowable working pressure, (at 120 °F) UG-27(c)(1)

P = S*E*t / (R + 0,60*t) - Ps= 16 700*0,70*0,0625 / (14 + 0,60*0,0625) - 0,19= 51,86 psi

Maximum allowable pressure, (at 70 °F) UG-27(c)(1)

P = S*E*t / (R + 0,60*t)= 16 700*0,70*0,0625 / (14 + 0,60*0,0625)= 52,05 psi

% Forming strain - UHA-44(a)(2)

EFE = (50*t / Rf)*(1 - Rf / Ro)= (50*0,0625 / 14,0313)*(1 - 14,0313 / infinity)= 0,2227%

17/46

Thickness Required Due to Pressure + External Loads

Condition Pressure P (psi)

AllowableStress BeforeUG-23 StressIncrease ( psi)

Temperature (°F)

Corrosion C(in) Load Req'd Thk Due to

Tension (in)

Req'd Thk Dueto

Compression(in)

St Sc

Operating, Hot & Corroded 0,01 16 700 7 633 120 0 Weight 0 0

Operating, Hot & New 0,01 16 700 7 633 120 0 Weight 0 0

Hot Shut Down, Corroded 0 16 700 7 633 120 0 Weight 0 0

Hot Shut Down, New 0 16 700 7 633 120 0 Weight 0 0

Empty, Corroded 0 16 700 7 778 70 0 Weight 0 0

Empty, New 0 16 700 7 778 70 0 Weight 0 0

Hot Shut Down, Corroded, Weight &Eccentric Moments Only 0 16 700 7 633 120 0 Weight 0 0

Allowable Compressive Stress, Hot and Corroded- ScHC, (table HA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 633 psi

S = 16 700 / 1,00 = 16 700 psi

ScHC = min(B, S) = 7 633 psi

Allowable Compressive Stress, Hot and New- ScHN

ScHN = ScHC

= 7 633 psi

Allowable Compressive Stress, Cold and New- ScCN, (table HA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 778 psi

S = 16 700 / 1,00 = 16 700 psi

ScCN = min(B, S) = 7 778 psi

Allowable Compressive Stress, Cold and Corroded- ScCC

ScCC = ScCN

= 7 778 psi

Allowable Compressive Stress, Vacuum and Corroded- ScVC, (tableHA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 633 psi

S = 16 700 / 1,00 = 16 700 psi

ScVC = min(B, S) = 7 633 psi

18/46

Operating, Hot & Corroded, Bottom Seam

tp = P*R / (2*Sc*Ks + 0,40*|P|) (Pressure)= 0,01*14 / (2*7 632,98*1,00 + 0,40*|0,01|)= 0"

tm = M / (π*Rm2*Sc*Ks) (bending)

= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 632,98*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*0,70*(0,0625 - 0 + (0)) / (14 - 0,40*(0,0625 - 0 + (0)))= 104,58 psi

Operating, Hot & New, Bottom Seam

tp = P*R / (2*Sc*Ks + 0,40*|P|) (Pressure)= 0,01*14 / (2*7 632,98*1,00 + 0,40*|0,01|)= 0"

tm = M / (π*Rm2*Sc*Ks) (bending)

= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 632,98*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*0,70*(0,0625 - 0 + (0)) / (14 - 0,40*(0,0625 - 0 + (0)))= 104,58 psi

19/46

Hot Shut Down, Corroded, Bottom Seam

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 632,98*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

Hot Shut Down, New, Bottom Seam

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 632,98*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

Empty, Corroded, Bottom Seam

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 777,62*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 777,62*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

20/46

Empty, New, Bottom Seam

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 777,62*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 777,62*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

Hot Shut Down, Corroded, Weight & Eccentric Moments Only, Bottom Seam

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 14,1 / (2*π*14,0313*7 632,98*1,00)= 0"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0)|= 0"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0) - (0)= 0"

21/46

Cylinder #1

ASME Section VIII Division 1, 2013 Edition

Component Cylinder

Material SA-240 316L (II-D p. 74, ln. 9)

ImpactTested Normalized Fine Grain

Practice PWHT Optimize MDMT/Find MAWP

No No No No No

DesignPressure (psi)

DesignTemperature (°F)

DesignMDMT (°F)

Internal 0,01 120 -20

Static Liquid Head

Condition Ps (psi) Hs (in) SG

Operating 1,7 47,0035 1

Test horizontal 1,01 28 1

Dimensions

Inner Diameter 28"

Length 41,75"

Nominal Thickness 0,0625"

Corrosion Inner 0"

Outer 0"

Weight and Capacity

Weight (lb) Capacity (US gal)

New 66,71 111,29

Corroded 66,71 111,29

Radiography

Longitudinal seam None UW-11(c) Type 1

Top Circumferentialseam None UW-11(c) Type 1

Bottom Circumferentialseam None UW-11(c) Type 1

22/46

Results Summary

Governing condition UG-16

Minimum thickness per UG-16 0,0625" + 0" = 0,0625"

Design thickness due to internal pressure (t) 0,0021"

Design thickness due to combined loadings + corrosion 0,0007"

Maximum allowable working pressure (MAWP) 50,35 psi

Maximum allowable pressure (MAP) 52,05 psi

Rated MDMT -320 °F

UHA-51 Material Toughness Requirements

tr = 1,71*14 / (16 700*0,7 - 0.6*1,71) = 0,002"

Stress ratio = tr*E* / (tn - c) = 0,002*0,8 / (0,0625 - 0) = 0,0262

Impact test exempt per UHA-51(g) (coincident ratio = 0,0262)

Rated MDMT = -320°F

Material is exempt from impact testing at the Design MDMT of -20°F.

Design thickness, (at 120 °F) UG-27(c)(1)

t = P*R / (S*E - 0,60*P) + Corrosion= 1,71*14 / (16 700*0,70 - 0,60*1,71) + 0= 0,0021"

Maximum allowable working pressure, (at 120 °F) UG-27(c)(1)

P = S*E*t / (R + 0,60*t) - Ps= 16 700*0,70*0,0625 / (14 + 0,60*0,0625) - 1,7= 50,35 psi

Maximum allowable pressure, (at 70 °F) UG-27(c)(1)

P = S*E*t / (R + 0,60*t)= 16 700*0,70*0,0625 / (14 + 0,60*0,0625)= 52,05 psi

% Forming strain - UHA-44(a)(2)

EFE = (50*t / Rf)*(1 - Rf / Ro)= (50*0,0625 / 14,0313)*(1 - 14,0313 / infinity)= 0,2227%

23/46

Thickness Required Due to Pressure + External Loads

Condition Pressure P (psi)

AllowableStress BeforeUG-23 StressIncrease ( psi)

Temperature (°F)

Corrosion C(in) Location Load Req'd Thk Due to

Tension (in)

Req'd Thk Dueto

Compression(in)

St Sc

Operating, Hot & Corroded 0,01 16 700 7 633 120 0 Top Weight 0,0001 0,0001

Bottom Weight 0,0007 0,0007

Operating, Hot & New 0,01 16 700 7 633 120 0 Top Weight 0,0001 0,0001

Bottom Weight 0,0007 0,0007

Hot Shut Down, Corroded 0 16 700 7 633 120 0 Top Weight 0,0001 0,0001

Bottom Weight 0,0007 0,0007

Hot Shut Down, New 0 16 700 7 633 120 0 Top Weight 0,0001 0,0001

Bottom Weight 0,0007 0,0007

Empty, Corroded 0 16 700 7 778 70 0 Top Weight 0,0001 0,0001

Bottom Weight 0 0

Empty, New 0 16 700 7 778 70 0 Top Weight 0,0001 0,0001

Bottom Weight 0 0

Hot Shut Down, Corroded,Weight & Eccentric MomentsOnly 0 16 700 7 633 120 0

Top Weight 0,0001 0,0001

Bottom Weight 0,0007 0,0007

Allowable Compressive Stress, Hot and Corroded- ScHC, (table HA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 633 psi

S = 16 700 / 1,00 = 16 700 psi

ScHC = min(B, S) = 7 633 psi

Allowable Compressive Stress, Hot and New- ScHN

ScHN = ScHC

= 7 633 psi

Allowable Compressive Stress, Cold and New- ScCN, (table HA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 778 psi

S = 16 700 / 1,00 = 16 700 psi

ScCN = min(B, S) = 7 778 psi

Allowable Compressive Stress, Cold and Corroded- ScCC

ScCC = ScCN

= 7 778 psi

24/46

Allowable Compressive Stress, Vacuum and Corroded- ScVC, (tableHA-4)A = 0,125 / (Ro / t)

= 0,125 / (14,0625 / 0,0625)= 0,000556

B = 7 633 psi

S = 16 700 / 1,00 = 16 700 psi

ScVC = min(B, S) = 7 633 psi

Operating, Hot & Corroded, Above Support Point

tp = P*R / (2*Sc*Ks + 0,40*|P|) (Pressure)= 0,01*14 / (2*7 632,98*1,00 + 0,40*|0,01|)= 0"

tm = M / (π*Rm2*Sc*Ks) (bending)

= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 632,98*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*1,00*(0,0625 - 0 + (0,0001)) / (14 - 0,40*(0,0625 - 0 + (0,0001)))= 149,5 psi

Operating, Hot & New, Above Support Point

tp = P*R / (2*Sc*Ks + 0,40*|P|) (Pressure)= 0,01*14 / (2*7 632,98*1,00 + 0,40*|0,01|)= 0"

tm = M / (π*Rm2*Sc*Ks) (bending)

= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 632,98*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

25/46

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*1,00*(0,0625 - 0 + (0,0001)) / (14 - 0,40*(0,0625 - 0 + (0,0001)))= 149,5 psi

Hot Shut Down, Corroded, Above Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 632,98*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Hot Shut Down, New, Above Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 632,98*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Empty, Corroded, Above Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 777,62*1,00)= 0"

26/46

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 777,62*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Empty, New, Above Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 777,62*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 777,62*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Hot Shut Down, Corroded, Weight & Eccentric Moments Only, Above Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*Sc*Ks) (bending)= 0 / (π*14,03132*7 632,98*1,00)= 0"

tw = W / (2*π*Rm*Sc*Ks) (Weight)= 79,2 / (2*π*14,0313*7 632,98*1,00)= 0,0001"

tt = |tp + tm - tw| (total, net compressive)= |0 + 0 - (0,0001)|= 0,0001"

tc = tmc + twc - tpc (total required, compressive)= 0 + (0,0001) - (0)= 0,0001"

Operating, Hot & Corroded, Below Support Point

tp = P*R / (2*St*Ks*Ec + 0,40*|P|) (Pressure)= 0,01*14 / (2*16 700*1,00*1,00 + 0,40*|0,01|)= 0"

27/46

tm = M / (π*Rm2*St*Ks*Ec) (bending)

= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -1 081,9 / (2*π*14,0313*16 700*1,00*1,00)= -0,0007"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0007)= 0,0007"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0007) - (0)|= 0,0007"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*1,00*(0,0625 - 0 + (-0,0007)) / (14 - 0,40*(0,0625 - 0 + (-0,0007)))= 147,61 psi

Operating, Hot & New, Below Support Point

tp = P*R / (2*St*Ks*Ec + 0,40*|P|) (Pressure)= 0,01*14 / (2*16 700*1,00*1,00 + 0,40*|0,01|)= 0"

tm = M / (π*Rm2*St*Ks*Ec) (bending)

= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -1 081,9 / (2*π*14,0313*16 700*1,00*1,00)= -0,0007"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0007)= 0,0007"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0007) - (0)|= 0,0007"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / (R - 0,40*(t - tm + tw))= 2*16 700*1,00*1,00*(0,0625 - 0 + (-0,0007)) / (14 - 0,40*(0,0625 - 0 + (-0,0007)))= 147,61 psi

28/46

Hot Shut Down, Corroded, Below Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*St*Ks*Ec) (bending)= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -1 081,9 / (2*π*14,0313*16 700*1,00*1,00)= -0,0007"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0007)= 0,0007"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0007) - (0)|= 0,0007"

Hot Shut Down, New, Below Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*St*Ks*Ec) (bending)= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -1 081,9 / (2*π*14,0313*16 700*1,00*1,00)= -0,0007"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0007)= 0,0007"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0007) - (0)|= 0,0007"

Empty, Corroded, Below Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*St*Ks*Ec) (bending)= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -15,8 / (2*π*14,0313*16 700*1,00*1,00)= 0"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (0)

29/46

= 0"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (0) - (0)|= 0"

Empty, New, Below Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*St*Ks*Ec) (bending)= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -15,8 / (2*π*14,0313*16 700*1,00*1,00)= 0"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (0)= 0"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (0) - (0)|= 0"

Hot Shut Down, Corroded, Weight & Eccentric Moments Only, Below Support Point

tp = 0" (Pressure)tm = M / (π*Rm

2*St*Ks*Ec) (bending)= 0 / (π*14,03132*16 700*1,00*1,00)= 0"

tw = W / (2*π*Rm*St*Ks*Ec) (Weight)= -1 081,9 / (2*π*14,0313*16 700*1,00*1,00)= -0,0007"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0007)= 0,0007"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0007) - (0)|= 0,0007"

30/46

Legs #1

Inputs

Leg material

Leg description 3 inch sch 40 pipe

Number of legs, N 4

Overall length 36"

Base to girth seam length 34"

Bolt circle 30,125"

Foundation allowable bearing stress 1 658 psi

User defined leg eccentricity 0

Effective length coefficient, K 1,2

Coefficient, Cm 0,85

Leg yield stress, Fy 36 000 psi

Leg elastic modulus, E 29 000 000 psi

Anchor Bolts

Anchor bolt size 0,375" series 8 threaded

Anchor bolt material

Anchor bolts/leg 1

Anchor bolt allowable stress, Sb 20 000 psi

Anchor bolt corrosion allowance 0"

Anchor bolt hole clearance 0,375"

Welds

Leg to shell fillet weld 0,0625" (0,0089" required)

Legs braced No

Note: The support attachment point is assumed to be 1 in up from the cylinder circumferential seam.

31/46

Governing Condition : Weight operating corroded, Moment = 0,0 lbf-ft

Forceattack

angle °

Legposition °

Axialend load

lbf

Shearresisted

lbf

Axialfa

psi

Bendingfbxpsi

Bendingfbypsi

RatioH1-1

RatioH1-2

0

0 319,3 0,0 143 0 0 0,0073 0,0066

90 319,3 0,0 143 0 0 0,0073 0,0066

180 319,3 0,0 143 0 0 0,0073 0,0066

270 319,3 0,0 143 0 0 0,0073 0,0066

Weight empty corroded, Moment = 0,0 lbf-ft

Forceattack

angle °

Legposition °

Axialend load

lbf

Shearresisted

lbf

Axialfa

psi

Bendingfbxpsi

Bendingfbypsi

RatioH1-1

RatioH1-2

0

0 48,2 0,0 22 0 0 0,0011 0,0010

90 48,2 0,0 22 0 0 0,0011 0,0010

180 48,2 0,0 22 0 0 0,0011 0,0010

270 48,2 0,0 22 0 0 0,0011 0,0010

Leg Calculations (AISC manual ninth edition)

Axial end load, P1 (Based on vessel total bending moment acting at leg attachment elevation)

P1 = W / N + 48*Mt / (N*D)= 1 277,11 / 4 + 48*0 / ( 4*28,125)= 319,28 lbf

Allowable axial compressive stress, Fa (AISC chapter E)

Cc = Sqr(2*π2*E / Fy)= Sqr(2*π2*29 000 000 / 36 000)= 126,0993

K*l / r = 1,2*35 / 1,1637 = 36,0909

Fa = 1 * (1 - (K*l / r)2 / (2*Cc2))*Fy / (5 / 3 + 3*(K*l / r) / (8*Cc)-(K*l / r)3 / (8*Cc

3))= 1 * (1 - (36,0909)2 / (2*126,09932))*36 000 / (5 / 3 + 3*(36,0909) / (8*126,0993)-(36,0909)3 / (8*126,09933))= 19 494 psi

Allowable axial compression and bending (AISC chapter H)

F'ex = 1*12*π2*E / (23*(K*l / r)2)

= 1*12*π2*29 000 000 / (23*(36,0909)2)= 114 645 psi

F'ey = 1*12*π2*E / (23*(K*l / r)2)

= 1*12*π2*29 000 000 / (23*(36,0909)2)= 114 645 psi

Fb = 1*0,66*Fy= 1*0,66*36 000= 23 760 psi

32/46

Compressive axial stress

fa = P1 / A= 319,28 / 2,23= 143 psi

Bending stresses

fbx = F*cos(α)*L / (Ix / Cx) + P1*Ecc / (Ix / Cx)= 0*cos(0)*35 / (3,02 / 1,75) + 319,28*0 / (3,02 / 1,75)= 0 psi

fby= F*sin(α)*L / (Iy / Cy)= 0*sin(0)*35 / (3,02 / 1,75)= 0 psi

AISC equation H1-1

H1-1 = fa / Fa + Cmx*fbx / ((1 - fa / F'ex)*Fbx) + Cmy*fby / ((1 - fa / F'

ey)*Fby)= 143 / 19 494 + 0,85*0 / ((1 - 143 / 114 645)*23 760) + 0,85*0 / ((1 - 143 / 114 645)*23 760)= 0,0073

AISC equation H1-2

H1-2 = fa / (0,6*1*Fy) + fbx / Fbx + fby / Fby= 143 / (0,6*1*36 000) + 0 / 23 760 + 0 / 23 760= 0,0066

4, 3 inch sch 40 pipe legs are adequate.

Anchor bolts - Weight empty corroded condition governs

Tensile loading per leg (1 bolt per leg)

R = 48*M / (N*BC) - W / N= 48*0 / (4*30,125) - 192,66 / 4= -48,16 lbfThere is no net uplift (R is negative).

0,375" series 8 threaded bolts are satisfactory.

Check the leg to vessel fillet weld, Bednar 10.3, Weight operating corroded governs

Note: continuous welding is assumed for all support leg fillet welds.

Zw = (2*b*d + d2) / 3= (2*3,5*1 + 12) / 3= 2,6667 in2

Jw = (b + 2*d)3 / 12 - d2*(b + d)2 / (b + 2*d)= (3,5 + 2*1)3 / 12 - 12*(3,5 + 1)2 / (3,5 + 2*1)= 10,1828 in3

E = d2 / (b + 2*d)= 12 / (3,5 + 2*1)= 0,181818 in

33/46

Governing weld load fx = Cos(0)*0 = 0 lbfGoverning weld load fy = Sin(0)*0 = 0 lbf

f1 = P1 / Lweld= 319,28 / 5,5= 58,05 lbf/in (V

L direct shear)

f2= fy*Lleg*0,5*b / Jw= 0*35*0,5*3,5 / 10,1828= 0 lbf/in (V

L torsion shear)

f3 = fy / Lweld= 0 / 5,5= 0 lbf/in (V

c direct shear)

f4 = fy*Lleg*E / Jw= 0*35*0,1818 / 10,1828= 0 lbf/in (V

c torsion shear)

f5 = (fx*Lleg + P1*Ecc) / Zw= (0*35 + 319,28*0) / 2,6667= 0 lbf/in (M

L bending)

f6 = fx / Lweld= 0 / 5,5= 0 lbf/in (Direct outward radial shear)

f = Sqr((f1 + f2)2 + (f3 + f4)2 + (f5 + f6)2)= Sqr((58,05 + 0)2 + (0 + 0)2 + (0 + 0)2)= 58,05 lbf/in (Resultant shear load)

Required leg to vessel fillet weld leg size (welded both sides + top)

tw = f / (0,707*0,55*Sa)= 58,05 / (0,707*0,55*16 700)= 0,0089 in

The 0,0625 in leg to vessel attachment fillet weld size is adequate.

Base plate thickness check, AISC 3-106

fp = P / (B*N)= 319,28 / (4*4)= 20 psi

tb =(N - (d - tL)) / 2*Sqr(3*fp / Sb)=(4 - (3,5 - 0,216)) / 2*Sqr(3*20 / 24 000)= 0,0179 in

The base plate thickness is adequate.

34/46

Check the leg to vessel attachment stresses, WRC 107 (Weight operating corrodedgoverns)

Applied Loads

Radial load, Pr 0 lbf

Circumferential moment, Mc 0 lbf-in

Circumferential shear, Vc 0 lbf

Longitudinal moment, ML 0 lbf-in

Longitudinal shear, VL 319,28 lbf

Torsion moment, Mt 0 lbf-in

Internal pressure, P 1,71 psi

Mean shell radius, Rm 14,0313"

Local shell thickness, T 0,0625"

Design factor 3

Maximum stresses due to the applied loads at the leg edge (includes pressure)

γ = Rm / T = 14,0313 / 0,0625 = 224,5

C1 = 1,75, C2 = 0,5 in

Local circumferential pressure stress = P*Ri / T =382 psi

Local longitudinal pressure stress = P*Ri / (2*T) =191 psi

Maximum combined stress (PL+P

b+Q) = 5 112 psi

Allowable combined stress (PL+P

b+Q) = ±3*S = ±50 100 psi

Note: The allowable combined stress (PL+P

b+Q) is based on the strain hardening characteristics of this material.

The maximum combined stress (PL+P

b+Q) is within allowable limits.

Maximum local primary membrane stress (PL) = 382 psi

Allowable local primary membrane stress (PL) = ±1,5*S = ±25 050 psi

The maximum local primary membrane stress (PL) is within allowable limits.

35/46

Stresses at the leg edge per WRC Bulletin 107

Figure value β Au Al Bu Bl Cu Cl Du Dl

3C* 26,8195 0,0617 0 0 0 0 0 0 0 0

4C* 28,9335 0,1044 0 0 0 0 0 0 0 0

1C 0,0625 0,1089 0 0 0 0 0 0 0 0

2C-1 0,0282 0,1089 0 0 0 0 0 0 0 0

3A* 8,938 0,0821 0 0 0 0 0 0 0 0

1A 0,0705 0,1023 0 0 0 0 0 0 0 0

3B* 24,4987 0,0541 0 0 0 0 0 0 0 0

1B-1 0,0262 0,0812 0 0 0 0 0 0 0 0

Pressure stress* 382 382 382 382 382 382 382 382

Total circumferential stress 382 382 382 382 382 382 382 382

Primary membranecircumferential stress* 382 382 382 382 382 382 382 382

3C* 16,6213 0,1044 0 0 0 0 0 0 0 0

4C* 35,1692 0,0617 0 0 0 0 0 0 0 0

1C-1 0,0848 0,0778 0 0 0 0 0 0 0 0

2C 0,0474 0,0778 0 0 0 0 0 0 0 0

4A* 16,2045 0,0821 0 0 0 0 0 0 0 0

2A 0,0394 0,0812 0 0 0 0 0 0 0 0

4B* 7,6465 0,0541 0 0 0 0 0 0 0 0

2B-1 0,0538 0,0594 0 0 0 0 0 0 0 0

Pressure stress* 191 191 191 191 191 191 191 191

Total longitudinal stress 191 191 191 191 191 191 191 191

Primary membranelongitudinal stress* 191 191 191 191 191 191 191 191

Shear from Mt 0 0 0 0 0 0 0 0

Circ shear from Vc 0 0 0 0 0 0 0 0

Long shear from VL 0 0 0 0 -2 554 -2 554 2 554 2 554

Total Shear stress 0 0 0 0 -2 554 -2 554 2 554 2 554

Combined stress (PL+Pb+Q) 382 382 382 382 5 112 5 112 5 112 5 112

* denotes primary stress.

36/46

Transition #1

ASME Section VIII Division 1, 2013 Edition

Component Cone

Material SA-240 316L (II-D p. 74, ln. 9)

ImpactTested Normalized Fine Grain

Practice PWHT Optimize MDMT/Find MAWP

No No No No No

DesignPressure (psi)

DesignTemperature (°F)

DesignMDMT (°F)

Internal 0,01 120 -20

Static Liquid Head

Condition Ps (psi) Hs (in) SG

Operating Large 1,7 47,0035 1Small 1,99 55,0035

Test horizontal Large 1,01 28 1Small 0,53 14,75

Dimensions

Inner Diameter Large 28"

Small 1,5"

Length 8"

Nominal Thickness 0,0625"

Corrosion Inner 0"

Outer 0"

Knuckle Thickness tkl 0,0625"

Radius r1 2,1675"

Weight and Capacity

Weight (lb) Capacity (US gal)

New 14,16 9,7

Corroded 14,16 9,7

Radiography

Longitudinal seam None UW-11(c) Type 1

Top Circumferential seam None UW-11(c) Type 1

Bottom Circumferential seam None UW-11(c) Type 1

37/46

Results Summary

Governing condition UG-16

Minimum thickness per UG-16 0,0625" + 0" = 0,0625"

Design thickness due to internal pressure (t) 0,0043"

Maximum allowable working pressure (MAWP) 23,83 psi

Maximum allowable pressure (MAP) 25,6 psi

Rated MDMT -320 °F

UHA-51 Material Toughness Requirements

tr = 1,71*28 / (2*0,4493*(16 700*0,7 - 0.6*1,71)) = 0,0045"

Stress ratio = tr*E* / (tn - c) = 0,0045*0,8 / (0,0625 - 0) = 0,0582

Impact test exempt per UHA-51(g) (coincident ratio = 0,0582)

Rated MDMT = -320°F

Material is exempt from impact testing at the Design MDMT of -20°F.

Design thickness, (at 120 °F) UG-32(h) (Large End)

Di = D - 2*r*(1 - cos(α))= 28 - 2*2,1675*(1 - cos(63,3005))= 25,6128"

t = P*Di / (2*cos(α)*(S*E - 0,60*P)) + Corrosion= 1,78*25,6128 / (2*cos(63,3005)*(16 700*0,70 - 0,60*1,78)) + 0= 0,0043"

Design thickness, (at 120 °F) Appendix 1-4(d) (Knuckle)

L = Di / (2*cos(α))= 25,6128 / (2*cos(63,3005))= 28,5022"

M = 0,25*(3 + Sqr(L / r))= 0,25*(3 + Sqr(28,5022 / 2,1675))= 1,6566

tk = P*L*M / (2*S*E - 0,20*P) + Corrosion= 1,78*28,5022*1,6566 / (2*16 700*0,70 - 0,20*1,78) + 0= 0,0036"

Small End design thickness (t = 0,0003") does not govern.

Maximum allowable working pressure, (Corroded at 120 °F) UG-32(h)

P = 2*S*E*t*cos(α) / (Di + 1,20*t*cos(α)) - Pskl

= 2*16 700*0,70*0,0625*cos(63,3005) / (25,6128 + 1,20*0,0625*cos(63,3005)) -1,77

= 23,83 psi

38/46

Maximum allowable working pressure, (Corroded at 120 °F) App 1-4(d) (Knuckle)

P = 2*S*E*tk / (L*M + 0,20*tk) - Ps

= 2*16 700*0,70*0,0625 / (28,5022*1,6566 + 0,20*0,0625) -1,77

= 29,17 psi

Small End MAWP (426,1 psi) does not govern.

Maximum allowable pressure, (New at 70 °F) UG-32(h)

P = 2*S*E*t*cos(α) / (Di + 1,20*t*cos(α))

= 2*16 700*0,70*0,0625*cos(63,3005) / (25,6128 +1,20*0,0625*cos(63,3005))

= 25,6 psi

Maximum allowable pressure, (New at 70 °F) App 1-4(d) (Knuckle)

P = 2*S*E*tk / (L*M + 0,20*tk)

= 2*16 700*0,70*0,0625 /(28,5022*1,6566 + 0,20*0,0625)

= 30,94 psi

Small End MAP (428,09 psi) does not govern.

% Forming strain - UHA-44(a)(2)

EFE = (50*t / Rf)*(1 - Rf / Ro)= (50*0,1391 / 0,8196)*(1 - 0,8196 / infinity)= 8,4865%

39/46

Thickness Required Due to Pressure + External Loads

Condition Pressure P (psi)

AllowableStress BeforeUG-23 StressIncrease ( psi)

Temperature (°F)

Corrosion C(in) Location Load Req'd Thk Due to

Tension (in)

Req'd Thk Dueto

Compression(in)

St Sc

Operating, Hot & Corroded 0,01 16 700 3 472 120 0 Top Weight 0,0024 0,0024

Bottom Weight 0,0001 0,0001

Operating, Hot & New 0,01 16 700 3 472 120 0 Top Weight 0,0024 0,0024

Bottom Weight 0,0001 0,0001

Hot Shut Down, Corroded 0 16 700 3 472 120 0 Top Weight 0,0024 0,0024

Bottom Weight 0,0001 0,0001

Hot Shut Down, New 0 16 700 3 472 120 0 Top Weight 0,0024 0,0024

Bottom Weight 0,0001 0,0001

Empty, Corroded 0 16 700 3 494 70 0 Top Weight 0 0

Bottom Weight 0 0

Empty, New 0 16 700 3 494 70 0 Top Weight 0 0

Bottom Weight 0 0

Hot Shut Down, Corroded,Weight & Eccentric MomentsOnly 0 16 700 3 472 120 0

Top Weight 0,0024 0,0024

Bottom Weight 0,0001 0,0001

Allowable Compressive Stress, Hot and Corroded- ScHC, (table HA-4)A = 0,125 / (Ro / te)

= 0,125 / (14,0625 / 0,0281)= 0,000250

B = 3 472 psiS = 16 700 / 1,00 = 16 700 psiScHC = min(B, S) = 3 472 psiAllowable Compressive Stress, Hot and New- ScHNScHN = ScHC

= 3471,8766 psi

Allowable Compressive Stress, Cold and New- ScCN, (table HA-4)A = 0,125 / (Ro / te)

= 0,125 / (14,0625 / 0,0281)= 0,000250

B = 3 494 psiS = 16 700 / 1,00 = 16 700 psiScCN = min(B, S) = 3 494 psiAllowable Compressive Stress, Cold and Corroded- ScCCScCC = ScCN

= 3493,8286 psi

Allowable Compressive Stress, Vacuum and Corroded- ScVC, (tableHA-4)A = 0,125 / (Ro / te)

= 0,125 / (14,0625 / 0,0281)= 0,000250

B = 3 472 psiS = 16 700 / 1,00 = 16 700 psiScVC = min(B, S) = 3 472 psi

40/46

Operating, Hot & Corroded, Top Seam

tp = P*R / [(2*St*Ks*Ec + 0,40*|P|)*cos(α)] (Pressure)

= 0,01*14 / [(2*16 700*1,00*0,70 +0,40*|0,01|)*cos(63,3005)]

= 0"tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= -1 098,6 /[(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]

= -0,0024"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0024)= 0,0024"

tc = |tmc + twc - tpc| (total, net tensile)= |0 + (-0,0024) - (0)|= 0,0024"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / ((R - 0,40*(t - tm + tw))*cos(α))= 2*16 700*1,00*0,70*(0,0625 - 0 + (-0,0024)) / ((14 - 0,40*(0,0625 - 0 + (-0,0024)))*cos(63,3005))= 223,87 psi

Operating, Hot & New, Top Seam

tp = P*R / [(2*St*Ks*Ec + 0,40*|P|)*cos(α)] (Pressure)

= 0,01*14 / [(2*16 700*1,00*0,70 +0,40*|0,01|)*cos(63,3005)]

= 0"tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= -1 098,6 /[(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]

= -0,0024"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (-0,0024)= 0,0024"

tc = |tmc + twc - tpc| (total, net tensile)= |0 + (-0,0024) - (0)|= 0,0024"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / ((R - 0,40*(t - tm + tw))*cos(α))= 2*16 700*1,00*0,70*(0,0625 - 0 + (-0,0024)) / ((14 - 0,40*(0,0625 - 0 + (-0,0024)))*cos(63,3005))= 223,87 psi

Hot Shut Down, Corroded, Top Seam

tp = 0" (Pressure)

41/46

tm = M / [(π*Rm2*St*Ks*Ec)*cos(α)] (bending)

= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -1 098,6 / [(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]= -0,0024"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0024)= 0,0024"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0024) - (0)|= 0,0024"

Hot Shut Down, New, Top Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -1 098,6 / [(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]= -0,0024"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0024)= 0,0024"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0024) - (0)|= 0,0024"

Empty, Corroded, Top Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= -14,2 /[(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]

= 0"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (0)= 0"

tc = |tmc + twc - tpc| (total, net tensile)= |0 + (0) - (0)|= 0"

Empty, New, Top Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)

42/46

= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= -14,2 /[(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]

= 0"

tt = tp + tm - tw(total required,tensile)

= 0 + 0 - (0)= 0"

tc = |tmc + twc - tpc| (total, net tensile)= |0 + (0) - (0)|= 0"

Hot Shut Down, Corroded, Weight & Eccentric Moments Only, Top Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*14,03132*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -1 098,6 / [(2*π*14,0313*16 700*1,00*0,70)*cos(63,3005)]= -0,0024"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0024)= 0,0024"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0024) - (0)|= 0,0024"

Operating, Hot & Corroded, Bottom Seam

tp = P*R / [(2*St*Ks*Ec + 0,40*|P|)*cos(α)] (Pressure)= 0,01*0,75 / [(2*16 700*1,00*0,70 + 0,40*|0,01|)*cos(63,3005)]= 0"

tm = M / [(π*Rm2*St*Ks*Ec)*cos(α)] (bending)

= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -3,5 / [(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]= -0,0001"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0001)= 0,0001"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0001) - (0)|= 0,0001"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / ((R - 0,40*(t - tm + tw))*cos(α))

43/46

= 2*16 700*1,00*0,70*(0,0625 - 0 + (-0,0001)) / ((0,75 - 0,40*(0,0625 - 0 + (-0,0001)))*cos(63,3005))= 4 476,16 psi

Operating, Hot & New, Bottom Seam

tp = P*R / [(2*St*Ks*Ec + 0,40*|P|)*cos(α)] (Pressure)= 0,01*0,75 / [(2*16 700*1,00*0,70 + 0,40*|0,01|)*cos(63,3005)]= 0"

tm = M / [(π*Rm2*St*Ks*Ec)*cos(α)] (bending)

= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -3,5 / [(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]= -0,0001"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0001)= 0,0001"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0001) - (0)|= 0,0001"

Maximum allowable working pressure, Longitudinal Stress

P = 2*St*Ks*Ec*(t - tm + tw) / ((R - 0,40*(t - tm + tw))*cos(α))= 2*16 700*1,00*0,70*(0,0625 - 0 + (-0,0001)) / ((0,75 - 0,40*(0,0625 - 0 + (-0,0001)))*cos(63,3005))= 4 476,16 psi

Hot Shut Down, Corroded, Bottom Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -3,5 / [(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]= -0,0001"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0001)= 0,0001"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0001) - (0)|= 0,0001"

Hot Shut Down, New, Bottom Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -3,5 / [(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]

44/46

= -0,0001"

tt = tp + tm - tw(totalrequired,tensile)

= 0 + 0 - (-0,0001)= 0,0001"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0001) - (0)|= 0,0001"

Empty, Corroded, Bottom Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= 0 /[(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]

= 0"tt = tp + tm - tw (total required, tensile)

= 0 + 0 - (0)= 0"

tc = tmc + twc - tpc(total required,compressive)

= 0 + (0) - (0)= 0"

Empty, New, Bottom Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)

= 0 /[(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]

= 0"tt = tp + tm - tw (total required, tensile)

= 0 + 0 - (0)= 0"

tc = tmc + twc - tpc(total required,compressive)

= 0 + (0) - (0)= 0"

Hot Shut Down, Corroded, Weight & Eccentric Moments Only, Bottom Seam

tp = 0" (Pressure)tm = M / [(π*Rm

2*St*Ks*Ec)*cos(α)] (bending)= 0 / [(π*0,81962*16 700*1,00*0,70)*cos(63,3005)]= 0"

tw = W / [(2*π*Rm*St*Ks*Ec)*cos(α)] (Weight)= -3,5 / [(2*π*0,8196*16 700*1,00*0,70)*cos(63,3005)]= -0,0001"

tt = tp + tm - tw (total

45/46

required,tensile)

= 0 + 0 - (-0,0001)= 0,0001"

tc = |tmc + twc - tpc|(total, nettensile)

= |0 + (-0,0001) - (0)|= 0,0001"

Appendix 1-5 calculations are not required for the transition large end as a knuckle is present.

46/46