1 SPP FIELDS MEP Main Electronics Package Preliminary Design Review Bill Donakowski...

-

Upload

harry-palmer -

Category

Documents

-

view

217 -

download

2

Transcript of 1 SPP FIELDS MEP Main Electronics Package Preliminary Design Review Bill Donakowski...

1

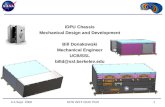

SPP FIELDS MEPMain Electronics Package Preliminary Design Review

Bill [email protected]

UCB/SSL13/14 NOVEMBER 2013

MAVEN PFDPUFlight Unit

SPP MEPBaseline Design

13/14 NOV 2013 B. Donakowski

SPP MEPPrototype Unit

MEP PDR Overview

• Requirements• Challenges• Design Overview• Design Heritage• Interlocking Frame Design• Board Layout Control Drawing• Daughter Board Details• Connectors Fastening• Thermal Design• FEM Dynamics Analysis• Vibration Testing • Mass Properties• Spacecraft Mounting• Ongoing Issues

213/14 NOV 2013 B. Donakowski

MEP Functional Requirements

• Provide Packaging for 9 different Board Assemblies in common box– LNPS1, LNPS2, MAGo, MAGi, RFS/DCB, DFB, AEB (2x),

TDS• Modular box arrangement allows individual boxes to

be built up independently and taken apart a/r• Design/Coordinate/Fab Box Frames with responsible

groups– UCB/MN/LASP/GSFC

• .060” thick Aluminum walls for Radiation Shielding • One plane mounting interface to Spacecraft• Adequate Structure Integrity (Strength, Dynamics)• Optimal thermal path to Spacecraft• Electrical Ground to S/C

313/14 NOV 2013 B. Donakowski

MEP Project Requirements

• Requirements per EDTRD, 7434-9039• Analysis/Design

– Materials selection, dynamics analysis, structural analysis, venting, EMI/EMC, grounding

• Testing/Verification– Mass Properties, Vibration, TVAC, Bakeout,

Cleanliness

413/14 NOV 2013 B. Donakowski

MEP Challenges

• Provide common module for different boards • Differing functions, connectors, and organizations

(UCB/LASP/MN/GSFC)• Box will be located in hot environment, must get

heat out of box as much as possible (Thermal environment: baseline 65 C)

• Modular Frames must fit well together into final structural/thermal package

• All frames must be in-plane for proper interface to Spacecraft Panel

• Limited Mass• Column Grid Arrays require conformance to

Steinberg requirements (separation of first natural frequencies of PWB and structure)

513/14 NOV 2013 B. Donakowski

MEP Box Overview

6

Attach surface to Spacecraft Panel

13/14 NOV 2013

10”

6.85”

8.25”

B. Donakowski

10 X #8 Fasteners

9 Individual Boxes

MAVEN Design Heritage

7

6x Skewers

Top EMI Shield over Card-Card Harnesses

S/C Bracket

Box Vents

Connectors on 3 sides of box

MAVEN Electronics Box•11 Separate Cards sharing common Frame details•Bolted to S/C Bracket on one Box face

Box Size: 8.1” Wide x 6.2” Tall x 9.3” Long

SPP FIELDS Electronics Box•9 Separate Cards sharing common Frame details•Bolted to S/C on one Box face

10x Attach feet to S/C(every other Frame)#8 Fasteners

(no shear panels)

Box Size: 8.25” wide x 6.85” Tall x 10.0” long

2x Skewers

Box Vents

Connectors on 3 sides of box

13/14 NOV 2013 B. Donakowski

2 Shear Panels

MEP Typ Box Frame Assy

8

Frame Instrument Connectors

EMI Shield

Mounting Surface to Spacecraft

Intrabox Connectors

Screws and Custom Inserts at PCB perimeter

Card PWB

Daughter Board (DCB, DFB, TDS)

13/14 NOV 2013 B. Donakowski

Box Machined Frame Design

9

Box Frame walls .060”

Multiple PCB attach screws to Frame to increase PWB stiffness and provide good thermal conduction path

Machined 6061 T6 Al Alloy Machined Frame.85” Pitch (Frame to Frame)

Feet for attachment to S/C

2 5-sided Framed Boxes (LNPS)

6X Skewers (#8 Threaded Rod)

13/14 NOV 2013

(OPEN)

B. Donakowski

7 Open Framed Boxes

Prototype Frame

Interlocking Frames Design

10

Individual Frames bolted together with 6X skewers

Detail showing Frame Interlocking

Features

Each Box can be Pulled From Stack

13/14 NOV 2013 B. Donakowski

Electronics Board Layout Control Drawing

11

Drawing Maintained by UCBDistributed to Electronics DesignersControlling Document for Design Consistency between EE and ME aspects

13/14 NOV 2013 B. Donakowski

PCB Attach Method

1213/14 NOV 2013

• Custom UCB designed insert• Stainless Steel, Silver Plated• Spiralock Threads provide

Locking Device• Insert soldered to PCB Traces• UCB will provide to outside

groups

B. Donakowski

Daughter Board Details

• DB Module to be designed/built by SSL• Large Chip (RJEX4000 CCGA) at Center• Used on DCB, TDS, DFB

13

Custom threaded tool thru threaded inserts applies gentle force at corners to remove DB from MB

4X Custom Tools

13/14 NOV 2013 B. Donakowski

Prototype Hardware

Connectors Fastening

14

UCB Custom Connector Nutplate

• Easier than nuts to assemble • no need to get wrench to hold nuts

during jackpost torquing• Standoffs can be removed one-by-

one

D-Connector

OTS Jackposts

Spiralock tapped holes

Desirement: Allow Jackposts to be Removed from outside of Box without opening box

Material: 6061 T6 Aluminum

13/14 NOV 2013 B. Donakowski

Thermal Design

• S/C environment is hot—testing at 65 C• Boards screwed to Frames at perimeter• 2X Screws at PCB center to EMI shield w/ integral posts• Attachment frame wet mounted to S/C (TBC)• All Exterior Surfaces painted with electrically conductive Black Paint (Aeroglaze Z307)• Black Anodize Interior Surfaces• Alodine 600 Treatment at Box interfaces (to PCB, SC, other Frames)

15

S/C

S/C

S/C

PCB screwed to EMI Shield (2x)

13/14 NOV 2013 B. Donakowski

Thermal Considerations: Center of PCB

• EMI Shield with integral posts to PCB• provide conductive path from center of PCB• Shield screwed to Frames at perimeter

16

Screws at perimeter to frame

Integral Posts at Center (fastened to PCB)

13/14 NOV 2013 B. Donakowski

PWB Thermal Design

• Consider entire heat path• Component To Board

– All components dissipating more than 50 mW should be looked at by thermal engineer

• Thermal / Ground / Power Planes– Board dissipated power needs to travel to the frame via

conduction in thermal (or ground) planes, then to the frame• Board Mounting to Box

– Need a good path from thermal planes to standoffs / box lip / wedge locks etc

• 2 Oz Copper Layers• Layouts to be reviewed by thermal engineer

1713/14 NOV 2013 B. Donakowski

MEP FEM Dynamics Analysis

• Requirements– Project: MEP Box First Natural Frequency > 100 Hz

• Easy to achieve– Project: PWB First Natural Frequency > 150 Hz

• Analysis: 190 Hz– Steinberg Design: First Natural Frequency separation of 2X

between individual PCB Assys and Entire Box (2 X 195 Hz = 390 Hz)

1813/14 NOV 2013 B. Donakowski

MEP FEM Dynamics Analysis

19

• PCB/Spacers/EMI Shield Assy

• Fixed at Perimeters (to Frame)

• Fn=195 Hz

• Entire MEP Box Assy• (PCBs/Frames)• Fixed at Attach Feet (to S/C)• Predict Fn > 500 Hz

Preliminary FEM Runs Encouraging•Fn > 100 Hz•Separation of 2X between PCB and Overall Structure •More detailed analysis required

• With completed LNPSs design

•Vibration testing of Prototype frames

13/14 NOV 2013 B. Donakowski

Vibration Testing

20

• Vibration Testing Performed 01 Nov 2013• Sine Survey Performed

– X Axis first mode: 376 Hz (perpendicular to PCBs)– Predict: > 500 Hz• Prototype Hardware First Mode frequency Lower than FEM

predicts• Required 2X frequency separation close• Further analysis required

13/14 NOV 2013 B. Donakowski

Mass Properties

• Current Estimate: 7.397 Kg• Continengency (20%): 1.479 Kg

• Current Best Estimate: 8.876 Kg

– (Intrabox Cables included, S/C cables not included)

2113/14 NOV 2013 B. Donakowski

Spacecraft Mounting

22

+Y Interior Panel

13/14 NOV 2013 B. Donakowski

Ongoing Issues

• EMI shielding of cables on top of Box TBD– Separate Aluminum EMI Shield– Wrapping individual cables with proper shielding

• FEM– Verify adequate frequency separation between box

structure and PWAs• Further analysis and test required

• Continue coordination with outside groups design efforts– LASP/MN: PWA (Connectors, EMI Standoffs, Dynamics,

Structural Properties)– GSFC: Box Frame (Interface Geometry to other Frames,

Dynamics, Structural Properties)• Grounding strap interface (APL to provide straps)

2313/14 NOV 2013 B. Donakowski