1 SPECIFICATIONS, CONCEPT GENERATION AND SELECTION SUMMARY Need Concept 1 Concept 2 Concept 3 …...

-

Upload

robert-maxwell -

Category

Documents

-

view

231 -

download

2

Transcript of 1 SPECIFICATIONS, CONCEPT GENERATION AND SELECTION SUMMARY Need Concept 1 Concept 2 Concept 3 …...

1

SPECIFICATIONS, CONCEPT GENERATION AND SELECTION SUMMARY

Need

Concept 1

Concept 2

Concept 3

…

Concept n

QFD

Functional Decomposition

Morphological Analysis

Ideation

Brainstorming

Patents

Reference (Books, Trade Journals)

Experts’ help

Feasibility judgment

Technology readiness

Go/no go screening

Decision matrix method

Final conceptRequired

functionality

Des

ign

rev

iew

1

Des

ign

rev

iew

2

2

1. Specification Development / Planning PhaseDetermine need, customer and engineering requirements

Develop a project plan

2. Conceptual Design PhaseGenerate and evaluate concepts

Select best solution

3. Detail Design PhaseDocumentation and part specification

Prototype evaluation

4. Production PhaseComponent manufacture and assembly

Plant facilities / capabilities

5. Service PhaseInstallation, use , maintenance and safety

6. Product Retirement PhaseLength of use, disposal, and recycle

IT IS TIME TO START THE NEXT DESIGN PHASE:

THE DETAILED DESIGN

3

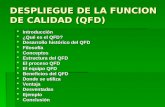

Quality function deployment

Gantt’s charts

Critical path method

Ideation

Brainstorming

Patents

Reference materials

Functional decomposition and morphological analysis

Sketches

Feasibility judgment

technology readiness assessment

Go/no-go screening

Decision matrix method (with pair-wise comparison)

CAD

Specification Development / Planning Phase

Conceptual Design PhaseConcept generation

Conceptual Design PhaseConcept selection

WE NOW NEED A NEW TOOL: CAD

Detailed Design Phase

4

Wire frame geometry

Solid geometry

Manual draftingElectronic drafting board

1970’s

1980’s

1990’s

Surface geometry

EVOLUTION OF CAD TOOLS

5

MODERN CAE TOOLS

CAD

SOLID, PARAMETRIC, FEATURE BASED

FINITE ELEMENT ANALYSIS

MOTION ANALYSIS

COMPUTATIONAL FLUID DYNAMICS

…..

…..

Computer Aided Design (CAD) is at the hub of other Computer Aided Engineering (CAE ) tools

6

IN MME2259a WE USE SolidWorks CAD SOFTWARE

You can burn your installation DVD on any lab computer

8

PARAMETER

BASE FEATURE(“POSITIVE” SOLID)

CHILD OF BASE FEATURE(“NEGATIVE” SOLID)

WHAT IS A SOLID, PARAMETRIC, FEATURE BASED CAD?

SOLID GEOMETRY

panel 01.SLDPRT

9

TO TAKE FULL ADVANTAGE OF A SOLID, PARAMETRIC,

FEATURE BASED CAD WE NEED TO UNDERSTAND HOW

TO USE IT.

WE’LL SPLIT OUR REVIEW INTO:

MODELING PHILOSOPHY

SKETCHES

FEATURES

PARTS

ASSEMBLIES

DRAWINGS

10

There is one factor of model building philosophy which stands above

others – what matters the most is what we want to do with the final

geometry.

Model geometry is not created to stay – it is meant to be changed.

We need to understand which features we would like to drive and

control some other ones, what portions are to be modified, what are

the boundaries of modifications; and anticipate how the model is going

to be developed further. All of this has to be incorporated in the model

history and developed to a state where the model “behaves” the

intended way. We call this The Design Intent.

MODELING PHILOSOPHY

11

The objective is not only to arrive to the destination – build the final

geometry – but to walk the journey towards it. Road to the

destination will teach us the reasons why and after arriving to the

destination we will start to understand. There are no shortcuts or

quick leaps there.

How does this all reflect on the model building techniques?

The model has to be able to easily handle changes down the road

(and, for sure, there will be changes). Changing basic dimensions,

changing number of features, changing shape – the model should

handle all such requests.

MODELING PHILOSOPHY

12

3D solid modeling software usually creates 3D geometry by taking

a 2D sketch and extruding, revolving, sweeping and blending it in a

“third“ direction which results in a 3D feature.

MODELING PHILOSOPHY

Both the sketch and the feature are parametric – dimension driven.

Changing the values of dimensions (if they are meaningful) forces

the geometry to assume new shape.

13

Proper feature geometry starts with proper parametric sketch.

Sketch is the entry point to incorporate design intent in the model.

Each 2D sketched entity will become a portion of a 3D feature, e.g.

lines will be converted to surfaces, endpoints become edges,

circles will become cylinders, etc.

90% of all errors are errors in sketches!

MODELING PHILOSOPHY

14

The way that geometry is built does not necessarily reflect

manufacturing process of a real, physical part. It rather resembles a

step-by-step approach by adding and subtracting material.

For example, while in real life a machined part is created always by

removing material only, 3D modeling combines solid protrusions

(adding) and cuts (removing) to build geometry.

This is why the dimensioning scheme on model cannot effectively

replicate manufacturing dimensioning scheme.

MODELING PHILOSOPHY

15

Sketch can be placed on a reference place or a flat face of already

existing geometry.

If possible, use underlying geometry to position sketch entities

SKETCHES

16

SKETCHES

Construct the first sketch on the first reference plane

Extrude in positive direction

Keep sketches simple

Use sketch relations where possible

Test relations by rebuilding sketch with different dimensions

Constrain all sketches

Give sketches some meaningful names

17

Sketch should not contain more than 12-15 geometric entities (lines, arcs,

conics, etc.) included construction geometry (centerlines, sketched

points). The more complex the sketch the harder is to control it with

minimum number of dimensions. Less is more.

Sketch implicit rules (assumptions or constraints) should be maximized to

simplify the geometry. Abundance of dimensions is worst than their

scarcity. The more dimensions we have to drive a sketch, the easier it is

to omit one when modifying feature geometry. This is one of the most

frequent mistakes.

SKETCHES

18

SKETCHES

Use relations in sketches

plate 001.prt

No symmetry relations With symmetry relations

19

SKETCHES

Use relations in sketches

plate 001.prt

20

Use construction geometry to create “intelligent” sketches.

Here we want to control the bolt circle diameter of three holes placed in

120º. increments about the center axis of a flange.

SKETCHES

sketch extrusion pattern

flange.prt

21

SKETCHES

“Massage” the sketch – change

values of crucial dimensions and

update it to find out if it behaves the

way you like.

flange.prt

Use underlying parent features for

proper alignments of sketches. This

will create parent-child relationship

between features. Use consciously

for controlling children through

parents

22

Exaggerate the sketch when creating features. Say we would like to sketch a line

1º. from vertical. It is easier to sketch it about 10º from vertical, dimension it and

modify the dimension to 1 deg, than try to sketch it almost vertical, dimension it

and expect the system to accept the value. The system’s implicit rules will kick-in

assuming the line should be vertical and we will have hard time to overrule it.

SKETCHES

23

SKETCHES

cup.prt

NO YES

Add details to features, not to sketches (also see the next slide)

24

BASE FEATURE

FILLET FEATURE

SKETCHES

cup.prt

25

Create main geometryThis is usually the main volume - the biggest feature, although it does not have to be. This feature becomes parent to majority of following features.

Add half-detailThese will be features like shells, construction ribs, cutouts, etc.

Finally create fine detailThese features are usually pick-and-place features such as rounds, chamfers, drafts, cosmetic grooves, etc.

FEATURES

Main geometry Half detail Detail

plate with boss.prt

26

When creating features avoid undesirable parent-child relationships. Features

representing “cosmetic” (fine detail) geometry should not be parent of any

subsequent features, unless driven by design intent

FEATURES

YES NO

plate with boss.prt

Cosmetic feature

Cosmetic feature

27

When orienting the sketch use construction planes, rather than solid

features in case the solid feature will be later redefined and its children

fail by losing their references.

FEATURES

YES

Sketch on reference plane

NO

Sketch on face

pipes.prt

28

When creating features of one kind (e.g. revolved), use the same

construction plane for sketching and orientation. Sketch the entities

always on the same side of the centerline of rotation (e.g. left-hand)

FEATURES

Axis of rotation

Sketch

pipes.prt

29

Avoid unattached geometry (two or more solid bodies within part).

The part geometry is by definition a continuum and should remain

continuum anytime during the history of feature creation.

FEATURES

NO

pipes.prt

30

All part features should be unsuppressed when releasing (making the final version) the part.

Part must have material property and color assigned

Part must not be in roll-back mode

Features and sketches must be named

All sketched must be fully defined

Use mm, N, s, K units ( important for analysis)

Zoom to fit and position in isometric view before saving

PARTS

31

ASSEMBLIES

Assembly of 3D solid modeling software in general does not

contain “assembly” geometry. The assembly contains

components (i.e. parts and lower level assemblies) assembled

together in the intended manner.

Assembly contains information on where to find parts and how

are parts oriented relative to each other (mated).

The only features that can be defined in assembly are “negative”

features (cut)

32

ASSEMBLIES

When retrieving the assembly (opening assembly file), CAD program

needs the following information:

- BOM (Bill of Material) structure: This information is stored within

assembly file and is used to retrieve all listed components. It is obvious,

that the system has to be able to “see” and retrieve all components

regardless where they reside on the network.

- “Mating” information: How feature surfaces of individual components are

assembled - mated to their parent components.

- Feature information: Assembly cuts (in case they have been created) and

parts/features that are being intersected by them.

33

ASSEMBLIES

BOM

MATING INFO

ASSEMBLY FEATURE (CUT)

shear pin.sldasm

34

ASSEMBLIES

bracket002.sldasm

Mating can use parts geometry or reference geometry