0601052 market assessment study for waste heat recovery power plant on sponge iron kiln exhaust i

description

Transcript of 0601052 market assessment study for waste heat recovery power plant on sponge iron kiln exhaust i

A

Project Report

On

“Market Assessment Study for Waste Heat Recovery Power Plant On

Sponge Iron Kiln Exhaust In India”

For

TRSANSPARENT ENERGY SYSTEMS PVT. LTD.

By

Ravi S. Ranjan

(Batch - 2006-08)

Under The Guidance Of

Prof. Sunil Doke

Submitted To

“University Of Pune”

In Partial Fulfillment of the Requirement for the Award of the Degree of

Masters of Business Administration (M.B.A.)

Through

Vishwakarma Institute of Management,

Pune-48.

1

ACKNOWLEDGEMENT

I express great pleasure in introducing my project report titled “Market assessment

study for waste heat recovery power plant on sponge iron kiln exhaust in India”.

I take this opportunity to express my most sincere and heartfelt gratitude to Mr. B. G.

Kulkarni (Director-Marketing & Sales) and Mr. Pankaj Bhangale (Manager-

Marketing), Transparent Energy Systems Pvt. Ltd., Pune, for providing me with a

wonderful opportunity to execute this project in their esteemed organization and for

patiently monitoring and guiding me throughout the project.

This project would not have been successful without the precious guidance of our

director Prof. Sharad Joshi and my project guide Prof. Sunil Doke, to whom I

express my sincere gratitude and all those who have helped me directly and indirectly.

Moreover, I would also like to thank all the employees of Transparent Energy Systems

Pvt. Ltd. for their constant support and help.

Once again I express my gratitude to TRANSPARENT ENERGY SYSTEMS PVT.

LTD. for providing me this enviable opportunity to carry out this project.

RAVI S. RANJAN

2

CONTENTS

Chapter Description Page No.

1. Executive Summary 1

2. Introduction 3

3. Company Profile 4

4. Objective And Scope Of The Project 11

5. Product Profile 12

6. Research Methodology 27

7. Research Analysis and Findings 31

8. Conclusion 39

9. Recommendations 40

10 Limitations of the Project 41

11 Bibliography 42

12 Annexure 43

3

CHAPTER 1

EXECUTIVE SUMMARY

TRANSPARENT ENERGY SYSTEMS PVT. LTD., Pune is one of the leading

companies in providing Waste Heat Recovery Solution to various manufacturing

industries. Last year the company achieved a huge success in offering Waste Heat

Recovery Solution to Cement Industry and on those grounds this year company had

targeted to offer similar solution to other industries. The objective of the project is to

determine the market potential for an industrial product i.e. waste heat recovery and

power generation system for Sponge Iron Industry. Transparent Energy Systems Pvt.

Ltd. is one of the umbrella companies of Transparent Group of Companies.

Transparent Energy Systems Pvt. Ltd have developed a state of art Heat Recovery

Boiler and Power Generation System using heat from exhaust gases of the rotary kiln

exhaust in sponge iron industry.

The company has been thinking of providing waste heat recovery and power generation

systems in the sponge iron industry. Hence the project was carried out to determine the

market potential for heat recovery and power generation systems. The field selected for

the survey was EAST & CENTRAL INDIA as there is high intensity of the targeted

market segment due to availability of iron ore which is the primary material used in the

manufacturing of sponge iron.

Transparent Energy Systems Pvt. Ltd. has a turnover of 75 crore as per the last

financial year. The industries selected for sample size were segmented according to size

of the plant, quantity of sponge iron manufactured daily/yearly, market share,

availability of waste heat from manufacturing process etc.

The data collected during the project was secondary as well as primary data. The

secondary data was collected to create the database of the survey. The sources used for

secondary data are various magazines, governmental & non-governmental publications

and internet. Beside this some places like chamber of commerce & industries, sponge

iron suppliers etc were sought to obtain information regarding the sponge iron

manufacturing plants. Some website regarding information of iron ore mines and

4

geography were also visited to get the information of availability of raw material in

particular region.

Primary data was collected through the questionnaire filled by industry visited.

The analysis was carried out on the basis of the information obtained from

questionnaire. The market potential was estimated by some assumptions for the waste

heat recovery and power generation systems.

From the analysis it is concluded that the waste heat recovery system has a very good

potential in Eastern and Central India Region.

After undergoing the project it is understood that even the analysis shows good

potential for waste heat recovery and power generation system, to make it practical, the

company has to arrange some awareness programs such as demonstrations, exposing

the product in exhibitions, etc.

5

CHAPTER 2

INTRODUCTION

Transparent Energy Systems Pvt. Ltd. has acquired proficiency in the entire

spectrum of products and technologies covering all possible facets of Energy

Efficiency, Environment Conservation and Cogeneration Business.

Transparent has developed a novel waste heat recovery & power generation system

using exhaust gases of the rotary kiln of the sponge iron industry.

In sponge iron industry the exit gases from rotary kilns of temperature 800°C-1000°C

are made to pass through a direct type of heat exchanger before passing it to the Electro

Static Precipitator (ESP) or Bag Filter. The exhaust gases are let into atmosphere

without doing any heat recovery from these gases. Thus a lot of energy goes wasted

from these exhaust gases into the atmosphere.

The basic system designed for recovering this heat consists of a combination of water

tube type boiler and economizers installed on various exhaust gas streams, steam

turbine driven electrical power gensets, water/air cooled condenser and condensate tank

& necessary temperature is made available for raw mills as well as coal mill.

Depending on availability of water in the area, system can be made water cooled or air

cooled. Systems that are air cooled are little more expensive than water cooled.

By using this type of a waste heat recovery and power generation system in the sponge

iron manufacturing plant, one can utilize the exhaust waste gases to generate power.

The power thus generated will be free of cost and will subsequently increase the plant

efficiency. Thus by maximum utilization of resource, the cost of production can be

drastically reduced.

This will provide the sponge iron company with an immense competitive advantage

over the long run.

6

CHAPTER 3

COMPANY PROFILE

Transparent Energy Systems Pvt. Ltd was incorporated on 16th April, 1986 with the

name of Vapour Energy Machines Pvt. Ltd. The first commercial production was

started in January, 1988.

The name of the company was changed from Vapour Energy Machine Private Limited

to Transparent Energy Systems Private Limited on 18th December, 1995.

Transparent Group of Companies are known as the technology leaders working in

the field of Co-generation systems, Ammonia Absorption Refrigeration Plants (AARP),

Water Recycling Plants, Super-efficient boilers and heaters, Waste Heat Recovery

Systems, Pollution Control Equipments, Drying Plants, Energy and Water Consultancy,

LiBr Chillers, Noise Abatement Products and Systems etc.

Transparent Energy Systems Pvt. Ltd. has acquired proficiency in the entire

spectrum of products and technologies covering all possible facets of Energy

Efficiency, Environment Conservation and Cogeneration Business. It has designed and

implemented over 150 installations of waste heat recovery and power generation alone

for different industries in India as well as numerous countries abroad.

The latest development of the company is a novel low pressure heat recovery and

power generation system using heat from exhaust gases of rotary kiln and clinker

cooler in cement industry. The company has received a patent from Government of

India for the boilers used in this kind of a system which is in addition to the numerous

other patents for its various systems and products.

The business divisions of Transparent Energy Systems Pvt. Ltd. includes the following

1. Heat Recovery Systems: -- Waste Heat Recovery Boilers and Systems.

2. Ammonia Absorption Refrigeration: -- Refrigeration up to -55° (know- how from

Mattes Engg. Germany)

7

3. Cogeneration Systems: -- Power, Heating and Chilling.

4. Boilers and Heaters: -- 95% super efficient oil/gas fuelled boilers, 89% super

efficient Agro fuelled/coal fired boilers, 93% super

efficient Thermic Fluid Heater/Hot air generators.

5. LiBr Chillers: -- Wide range of heat inputs viz.--Low and Medium

pressure steam/super heated hot water. Special proven

design to utilize heat from low temperature hot water of

55° C or higher.

6. Evaporators & Water Recycling: -- Multistage evaporators/desalination.

7. Energy and Water Consultancy: -- Energy/Water conservation.

The other umbrella companies of Transparent Group of Companies are listed below:

Transparent Technologies Pvt. Ltd

- Dryers, Coolers, Granulators, Waste to Energy Incinators, Evaporators and

Concentrators.

Ecokleen Pollution Control Pvt. Ltd

- Pollution control, Flue gas desulphurization plants, Fume & Dust extraction plants,

Air Stripping Plants & Airborne solvent vapour Recovery Plant, Thermal Oxidation

System of Airborne Solvent Vapours, Bulk material handling.

Decimin Control Systems Pvt. Ltd.

- Noise Abatement Products and Systems (in collaboration with IAC-BOET

STOPSON, France)

8

COMPANY POLICIES

MISSION:

To provide Sustainable solutions in Energy and Environment and be Loyal to Energy

Resource Conservation.

VISION:

To be globally respected high performance organization offering sustainable solutions

in energy and environment.

BUSINESS PHILOSOPHY:

Loyal To Energy Resource Conversation

On this principle Transparent Energy System has developed energy-efficient and eco-

friendly solutions for industry and commerce. For over 2 decades. Transparent Energy

Systems has been helping customers improve their processes, conserve energy, increase

their competitiveness and adhere to environmental norms.

Transparent Energy Systems equipments helps several tens of thousands of customers

the world over enjoy increased profitability, and earn community goodwill by:

Maximizing energy efficiency and slashing operating costs.

Minimizing waste.

Recovering precious resource from waste.

Keeping pollutants out of the water and the air.

9

BUSINESS AREAS:

In focus with the business mission; to provide Sustainable solutions in Energy and

Environment, and loyal to energy resource conservation Transparent Energy Systems

core business areas are

Boilers and Heaters

Absorption Cooling

Water and Waste Solutions

Chemicals for Energy and Environmental applications

Captive Power and Cogeneration systems

Air Pollution and Purification

Transparent Energy Systems provides standard products in these areas of business.

Drawing on decades of research and experience in process productivity improvement

and energy generation, Transparent also customizes integrated sustainable solutions for

the project requirements of a wide range of industries.

10

Marketing Poli cy

The company depends for is survival on its customers. The company believes that

everyone can contribute to customer satisfaction.

Guidelines and Norms for every employee in the organization, no matter in what

function or level he/she is in, have a responsibility towards the customer.

Everyone is expected to provide the best possible service to the next person in the chain

so that the ultimate service which we give to the customer is the best.

Everyone is expected to see the person, who requests his service as his customer.

In all situations, employees are expected to be courteous and responsive to external as

well as internal customers.

Every communication is to be acknowledged at the earliest even if a specific response

or decision may take a longer time.

The deadline or target date for finishing a task or for giving a decision should be

communicated along with the acknowledgement.

Anyone who has a problem, whether within the organization or outside, must be heard

and helped out to the best of one’s ability.

After action has been completed, a check for customer satisfaction must be undertaken,

as far as possible.

Every employee should ensure that commitments given to the customer are honoured

and we do not try and short-change the customer.

In whatever we do, we should aim for the highest quality and continuous improvement.

11

Quality Policy

Our Quality policy starts and ends with the customer as a focal point, understanding the

customer’s requirements, designing optimal solutions to meet those requirements,

building systems and processes in place to ensure quality at every stage, and achieving

our commitments on delivery and service before and after sales.

It is our endeavour to create a culture of Total Quality where continuous improvement

of our people, our processes and our products become a way of life.

12

Organization Structure of Transparent Energy Systems Pvt. Ltd.

Director Finance

Director HR Director Design

Director Marketing & Sales

Director Production

A.V.P. Finance

A.V.P. HR Sr. Design Engineer

Accountant Executive Jr. Design Engineer

V.P. Production

Sales Manager Marketing Manager

Sales Engineer

Sales Engineer

Marketing Engineer

Marketing Engineer

Worker Production Supervisor

Asst. Manager Production

Production Manager

13

MANAGING DIRECTOR

CHAPTER 4

OBJECTIVE AND SCOPE OF THE PROJECT

OBJECTIVES OF THE PROJECT:

Find the brand penetration of TESPL in the market.

Find out geographically the location of all sponge iron plants.

To find out market potential for Waste Heat Recovery and Power Generation

System.

To educate the sponge iron companies about the Waste Heat Recovery System

and its benefits.

To find out cost benefit analysis after doing heat recovery.

To find out the obstacles for implementing Waste Heat Recovery and Power

Generation Systems.

SCOPE OF THE PROJECT:

The project was carried out specifically in Sponge Iron Industry.

The product selected for the project was Waste Heat Recovery and Power

Generation System.

The region of East & Central of India was selected for operations.

The states of Orissa and Chattisgarh were covered to complete the market

survey.

14

CHAPTER 5

PRODUCT PROFILE

Waste Heat Recovery & Power Generation in Sponge Iron Plant

In Sponge Iron Plant Rotary Kilns are used which operate at around 900°C to 1100°C

temperature. The outgoing gases from these equipments are used to heat the incoming

feed material.

A lot of exhaust gases come out from these kilns which are sponge iron dust laden.

Hence they are passed through Electro Static Precipitators (ESPs)/ Bag Filters before

exhausting to atmosphere.

But before passing through ESP or bag filter these gases are made to pass through a

direct mixing type heat exchanger where the temperature of the exhaust gas is brought

down to 175°C. Due to this type of heat exchange process the waste heat available in

the exhaust gases goes waste into the atmosphere without being utilized. This in turn

also harms the atmosphere of the surrounding and increase global warming.

Thus a huge amount of heat is being wasted in sponge iron plants.

A novel waste heat recovery and power generation system has been designed using heat

from the exhaust gases of rotary kiln of the sponge iron plant.

15

Block Diagram of Waste Heat Recovery and Power Generation

System

WASTE HEAT RECOVERYSTEAM BOILERVERTICAL CO FLOW CONSTRUCTION SPECIAL DESIGNFOR SPONGEIRON PLANTS

SCREW CONVEYER FOR AUTOMATIC DUST REMOVALWITH COOLING ARRANGEMENT

GASES FROMBYPASS

TO EXHAUST GASCLEANING SYSTEM

Radiationzone

SUPERHEATER

EVAPOURATOR

ECONOMISER

SUPERHEATED STEAM

STEAM TURBINE

STEAM DRUM

SOOTBLOWER

SOOTBLOWER

FEED WATER

ALTERNATOR

CONDENSERCONDENSATE RETURN

ELECTRICAL POWER

Automatic 3 wayWater cooledDivertor valve

Flue gas from Kiln/ Furnace

WATER COOLEDJACKET

BYPASS PORT

16

Following issues need to be addressed while designing Waste Heat Recovery in Sponge

Iron Plant.

1. Methods of avoiding Deposition of Sponge iron dust on the Heat Transfer

Surface which otherwise results in fouling and lesser heat recovery.

2. Methods of dislodging deposited dust and keep the heat transfer surface free of

dust.

3. Avoid exposure of the flue gases to cold surface of the equipment during start-

up or interruptions. Otherwise this results in condensation f the flue gas

moisture and when this moisture comes in contact with sponge iron dust, it gets

“set” on the surfaces which are difficult to remove. Hence slow build-up of such

patches results in choking of the system & reduction in effectiveness of heat

transfer surface.

4. Availability of the water and its appropriate utilization to conserve the water by

designing the system judiciously.

5. Selection of appropriate electrical power generation system to maximize the

power generation.

6. Bringing down the flue gas exhaust temperature to sufficiently low level, so that

less expensive method of gas cleaning (after Heat Recovery) from flue gases

can be utilized.

7. Keep flue gas pressure drop in boiler low to economize on fan power.

8. Utilize vertical elevation available while configuring boilers.

9. Easy and continuous removal of sponge iron dust separated in boiler.

10. Automatic diversion and bypass of hot gases to gas washer / cooler in case of

boiler safety / abnormal boiler working conditions.

11. The system engineered should have attractive payback periods satisfying the

investment criteria.

17

Nature of Present Invention

It relates to

a) Use of high pressure steam boilers for heat recovery from gases at about 900°C.

b) Running steam engine driven gensets (or steam turbine gensets) to produce

electrical power.

c) Condense the steam utilized in gensets by air-cooled condensers.

d) Recycling and reuse of steam condensate for water conservation along with

waste heat recovery.

Deficiencies In The Prior Art

Heat Recovery from the Sponge Iron Plant hot exhaust is a difficult issue because of

the following problems faced –

a) Design which satisfies various objectives simultaneously (mentioned above in

point 1 to 11) is not available.

b) These gases have lots of dust content which gets deposited on the heat recovery

surfaces causing a lot of fouling.

c) If the gases are cooled below dew point, water condenses and comes in contact

with dust forming hard mass on the equipment surface. This results in choking

of the system subsequently, resulting in low heat recovery.

d) Lot of water is wasted in cooling the gases before they are sent to ESP.

Normally Sponge iron plants are in arid areas. Hence availability of water is

scarce especially during summer. Increasing population is further creating

higher priority for use of scarce water for domestic purposes and water may not

be available for sponge iron industry.

18

Description of the Present Invention

Following equipments are used for heat recovery

1. High Pressure Boiler

2. High Pressure Economizer

3. High pressure steam engine based electrical power genset.

4. Finned type air-cooled steam condenser.

5. Screw Conveyor at bottom of boiler for dust removal.

19

System Construction:

The basic system consists of water tube type boiler and economizer, steam engine

driven electrical power gensets, finned type air-cooled condenser and condensate tank.

Boiler and Economizer id made with slender tubes, typically 25.4 mm OD and are

about 10-12 meter long, arranged vertically. The size & length of tubes will change if

gas quantity & temperature changes. Tubes in one row have a common header at the

top and bottom forming on cassette of that row. Many such cassettes are kept adjacent

to each other forming square matrix of the tubes. All these tubes are supported only at

the top so that they are freely hanging under self weight of the boiler / economizer. This

eliminates possibilities of tube buckling due to thermal expansion.

Intermediate horizontal supports are provided between the gaps at regular intervals of

about 1.5 meter. These supports prevent bending of the tubes. Also vibrators / hammers

can be given on these supports so the removal of dust from the tube surface can be done

easily. The top face of these supports is given inclination of 60° with respect to

horizontal. Hence dust falls freely from those and doesn’t accumulate on the top face of

the supports.

The gases enter the system from the top and move downwards. Velocity of the gases is

kept lower so that the dust separates by gravity and pressure drop across the system

remains minimum & keeps the exhaust gas handling fan power to minimum.

The “Co-current down flow arrangement” for air and dust greatly enhance the

movement of the separated dust to the lower portion without accumulation or

depositing in the system, minimizing / eliminating fouling or choking. The gravitational

flow of the dust also eliminates additional power requirement for its conveying.

A screw conveyor is provided at the bottom of the system to remove the separated dust

particles, reducing dust load on ESP or Bag house.

The steam generated is stored in a steam drum having various safety mountings and

controls. From here the steam is supplied to the Steam Engine Driven Genset to

generate electrical power. Back pressure on the Steam Engine is kept slightly above

atmospheric pressure.

20

Steam exhausted from Steam Engine is condensed in a finned type air-cooled steam

condenser. The condensed water is stored in condensate tank and re supplied to the

economizer as feed water. Thus water circuit forms a closed loop conserving lot of

water and also eliminates need of large capacity elaborate water softeners which

otherwise would have been necessary for input water treatment.

The condenser also is selectively kept air-cooled and not water –cooled type to

minimize the use of water in the plant.

In steam based power generation Steam Engines is preferred to Steam Turbine since

Steam Engine is much more efficient and generates almost double the power.

Condensation of moisture in the flue gas will endanger the system. Since that water

when comes in contact with the dust particles will form the hard mass on the tube

surface causing fouling / choking of the system. Hence the flue gas temperature should

always be kept above the dew point. Hence for cold start or during any interruption in

the Heat Recovery Boilers, steam is supplied to the system by a start-up boiler to keep

the temperature at the required level. The system is automatic. It senses temperature &

pressure inside the boiler & steam admission is initiated from ‘start up’ boiler. This

start up boiler can be Gas / oil fired and draws input water from the condensate tank

itself.

The salient features are as follows:

1. All the boilers and economizers are arranged one above the other vertically

which allows downward movement of the flue gas from top to bottom.

2. Typically hot gas is let out from the kilns at a considerable height. Hence it

eliminates additional ducting.

3. Boilers and economizers are water tube type with tubes hanging vertically.

Water is inside the tubes and flue gas outside the tube.

4. Tubes have intermediate supports at about 1.5 meter pitch which keeps the

tubes straight.

21

The top faces of intermediate supports are given 60° slant angle from horizontal, so

that particle dislodged from tube surface doesn’t accumulate on these supports but

slides down easily on the slant.

The downward flow of the flue gases and gravity fall of dust particle greatly and

easily “co-operate” each other to reach bottom with following advantages-

a) The flue gas velocities can be much lower than pneumatic conveying velocities.

This benefits in-

Lower frictional pressure loss in flue gas flow saving energy in fan power

required.

Gravitational energy used for sponge iron dust. Hence flue gases don’t have

to be imparted additional energy, otherwise required for pneumatic conveying,

saving pneumatic conveying energy.

This greatly increased net electrical energy exported for external use.

b) Vertical downward “parallel to heat transfer area” flue gas flow with free

flowing gravity force driven dust particle eliminates any possibility of

redeposition of sponge dust on tubes.

Due to this the boiler heat recovery is very effective and tube fouling (which

reduces effectiveness of heat transfer area) is lowest.

If the fouling were to be high, then the heating surface required would have to be

much higher. Increase in boiler heating surface, increase boiler steel requirement,

increase dry and operating weight of boiler. The increased boiler weight increases

structural support steel quantities.

All these greatly increase initial cost (capital cost) of the equipment.

Therefore, the clean surface means lower initial cost.

Also if boiler has higher heating surface it has higher flue gas pressure drop (flue

gas frictional resistance). So fan consumes more power reducing net power

exported from heat recovery co-generation system.

22

Therefore excessive fouling of ‘Heating Transfer Surface’ will reduce the

commercial viability of the project.

5. Mechanical vibrators or hammers are provided to dislodge the powder

deposited on the surface. System is fully automatic

Automation is either based on preprogrammed on & off cycle timing of vibrators /

Hammers or it works on gas pressure drop across the boiler.

The automatic system working on Flue Gas Pressure is as follows:

A separate differential gas pressure switch is provided across each boiler &

economizer. If the pressure drop increase beyond desired set pint (set level) the

vibrators / hammers will work “continuously” or “continuously cyclically” till

pressure drop comes back within desired limit.

Powder dislodged from tube surfaces due to hammering / vibrations falls freely

downwards without obstruction through uniform flue gas passage.

6. All the tube headers are supported at the top only so that-

a. Tubes remain straight avoiding buckling.

b. Tubes are free to expand thermally which leaves the system without any

strain.

c. Tubes remain in tension by force equal to gravity weight of the boiler,

giving better life. Since metal has higher tensile strength than

compressive strength.

7. To avoid condensation in the flue gases, in cold start, a start–up boiler is

provided which pre-heats the entire system to about 140°C-150°C.

8. Till this initial temperature is reached the ‘Diverter Valve’ at the entry point of

the flue gases by-passes the flue gases to water spray tower. Hence there cannot

be choking of the system due to hardening of the dust-water mixture.

9. Finned type air-cooled steam condenser, condenses the used steam, which is

stored in a condensate tank. This condensate water at 105°C is used as feed

water to the economizer and boilers.

23

10. Speed of the “Cooling Air Fan” of air-cooled condenser is controlled by

monitoring condenser inlet pressure through a pressure transmitter & variable

speed drive. This conserves fan energy & also avoids excessive cooling of the

condensate water.

Safeties and Inter locks

A) A pneumatic cylinder operated “Three way diverter valve” (refer sketch) is

fitted on the entry point of the hot gases and the hot gas passage is automatically

diverted to the water spray tower in the following cases-

a. Waste Heat Recovery Boiler / economizer temperature is lower than the

required level.

b. The flue-gas temperature at inlet is lower than the required temperature.

c. The steam pressure in the steam drum is out of the desired upper and

lower limit.

d. Boiler water level is low.

e. Boilers feed pump trips.

f. Steam pressure of the start up boiler lower than desired.

g. Power supply of cogen plant is OFF.

B) Operation of the engine is sensed all the time by a speed sensor. In case the

engine stops, a control valve in the by-pass line opens diverting the steam

directly to the air-cooled condenser.

C) A pressure transmitter senses the input pressure to the air-cooled condenser

keeping constant back pressure on the steam engine. It also gives signal to the

variable speed drive of the condenser blower. This controls the blower rpm to

desired level, conserving electrical power.

D) Functioning of low temperature safety (Start-up Boiler):

To prevent the contact of flue gases with low temperature metal surface, this

safety is incorporated. This avoids condensation of water vapor in flue gases

and resultant hard mass formation of dust powder and water.

A start-up boiler is always kept at about 140°C as standby or “Banked

Position”. Whenever flue gas flow is stopped, waste heat recovery also will not

24

take place. The steam pressure in the steam drum will droop operating the

pressure switch. This controls following three functions:

1) Control valve at the start-up boiler main stream outlet is opened which

supplies steam to Economizer and Main Boiler.

2) 3 way valve between economizer and boiler operates and supplies the

steam to the ejector which draws high temperature water from the steam

drum to heat the boiler tubes.

3) The control valve between the economizer and boiler, which is on the

opposite side of the 3 way valve also opens and supplies start-up boiler

steam to the main boiler tubes.

Thus in no case the system temperature is allowed to drop below the desired

level avoiding water condensation and choking of the flue gas path.

Advantages of the Present invention

1) Low pressure drop on the flue gas, conserving fan power.

2) Flue gas and dislodged sponge iron dust both move in the downward direction

resulting in self cleaning process.

3) Automatic vibrators / mechanical hammers dislodge the settled powder easily.

4) Free hanging tube design under self-weight prevents bending / buckling of the

tubes.

5) Dust deposition and fouling being avoided, heat transfer effectiveness assured.

6) Provision of start-up boiler & automatic instrumentation avoids cold-start and

condensation problems. This further eliminates the possibility of choking of the

system.

7) Automatic diverter valve at the flue gas entry gives improved safety on system

choking and over heating of the system.

8) Start up boiler is always at 140°C minimum i.e. in “Banked Position” to keep

the system at 140°C, even in case of flue gas flow failure.

9) Closed loop water system conserves huge amount of water. Also it eliminates

the need for large capacity water softeners which otherwise would have been

necessary for boiler feed water.

10) Electrical power generated gives additional earnings to make the system viable.

25

Conservation of Water

Tremendous quantity of water is conserved due to following:

1. Cooling of hot gas in Waste heat recovery boiler, drastically reducing the

quantity of water required in spray tower.

2. Closed loop water circuit facilitating use of condensed water.

3. Use of finned type air cooled condenser instead of water cooled condenser.

26

CASE STUDY

Transparent Energy Systems Pvt. Ltd. has designed one such heat recovery systems.

The description of the design is as follows:

BASIS OF DESIGN / HEAT SOURCE DETAILS :

Source Equipment Furnace

Media of Waste

Heat

Exhaust Gas

Rated Capacity TPD 100 X 2

Exhaust Gas

Temperature

Deg.C 1000

TECHNICAL SPECIFICATIONS OF EXHAUST GAS HEAT RECOVERY SYSTEM MODEL

‘RECOPOWER’

Model of Heat

Recovery

Steam Generation

Steam Condition Super heated

Heat Recovery

Equipment

Exhaust Gas Heat Recovery Boiler with Economizer

Installation Vertical

27

STEAM GENERATION DETAILS

- f & a 100

Deg CKg/hr 26805

- f 105oC &

at 64

kg/sq.cm(g)

& 490oC

Kg/hr 20517

Power output details

Inlet steam

pressure

Kg/

sq.cm(g)64

Inlet steam

temperatureDeg.C 480

Condenser

Pressureata 0.12

Steam flow

through

turbine

Kg/hr 20517

Net Power

output from

the turbine

Kwe 4460

28

ESTIMMATED SAVIANGS AND PAYBACK CALCULATIONS DUE TO INSTALLTION OF

WASTE HEAT RECOVERY POWER PLANT

DISCRIPTION UNIT PARAMETER

Net Heat Recovery from the exhaust Kcal/hr 14474699

Power generation from the exhaust Kwe 4460

Estimated Savings Calculations

Auxiliary power consumption due

waste heat recovery system

Kwe 340

Net power available from the system Kwe 4120.20

Cost of electricity Rs/Kwe 3.8

Hourly saving in cost of electricity Rs/hr 15656.8

Estimated annual working hours Hr 8000

Annual savings in cost of electricity Rs in lakh 1252.5

Estimated Payback calculations

Total Estimated initial investment Rs in lakh 2000

Estimated payback period Months 8.1

Note: Approximate initial investment is an indicative figure and may vary upon the site conditions.

Cost of electricity is assumed to be Rs. 3.8 per Kwe for calculations.

These savings calculations are submitted to assist the customer to access the economic feasibility of

the project. Saving on annual operating costs may vary depending on the load on equipment, cost of

electricity, operating hours etc.

29

CHAPTER 6

RESEARCH METHODOLOGY

RESEARCH METHODOLOGY

The methodology is basically the set of rules, procedures, tools, and techniques used by

the researcher for realization of research objective. The process of designing research

study involves many interrelated decisions.

The most significant decision is the choice of research approach. This determines how

the information will obtain.

The question of my research was how to implement components of marketing strategy

for the company in terms of brand penetration and offering differentiation in WHRS

solution in comparison with the competitors of TESPL.

There are three types of research approach: -

1) Exploratory research

2) Descriptive research

3) Causal research

These types differ significantly in terms of research purpose, research question,

precision of hypotheses that are formed and data collection method used.

1) Exploratory research: -

Exploratory research is seeking insight into general nature of a problem, the

possible decision alternatives and relevant variables that need to be considered.

The objective of exploratory research is to find out new ideas flexibility, &

ingenuity characterized by the investigation. In the exploratory research emphasis

is given on the finding practices and policies that need changing and developing

possible alternatives. Exploratory research seeks to discover new relationships.

Hence most of the marketing research is of an exploratory type. Exploratory

research defines problem, which is then solved by conclusive research.

30

In my project the exploratory research was carried out by finding the sponge iron

industries located in India using the internet and the various websites like

www.osima.com which also gave the plant capacities of the sponge iron plants

and important phone numbers. Also I was able to locate the geographic locations

of the plants with the help of this site, which aided me in planning my tour plan.

2) Descriptive research: -

Descriptive research gives emphasis on description & such studies are simply fact

gathering expedition. Descriptive studies attempt to obtain a complete & accurate

description of situation. Descriptive data are based as direct basis for marketing

decisions.

In my project descriptive research works was carried out by interviewing the

customers personally and explaining to them the benefits of using WHRS and

also convince them to place an enquiry in the company to carry out further

dealings.

In planning and designing a specific research project it is necessary to anticipate

all the points that must be undertaken if the project is to be successful in

collecting valid and reliable information.

The steps in which the project was carried out were as follows: -

1) Define the problem and specify objective.

2) Developing research plan.

3) Design the data collection method.

4) Organize and carryout the field work

5) Analyze the collected data

6) Presentation of the project report

The analysis was done using pie chart and the collected data is tabulated in the tabular

form. The finding of each graph is written bellow the graphs.

31

SAMPLING DESIGN

The techniques of sample are classified as:

1) Probability sampling method.

These methods are generally applied in case of important decisions, where accuracy is

at a premium, regardless of the time and cost involved, in plain terms, every member of

the population has an equal chance of selection.

2) Non probability sampling method.

Samples are selected according to convenience of the researcher in non-probability

sampling. So it has the benefits of simplicity and low cost. This sampling does not

provide a chance of selection to each population element.

In the project non-probability sampling method was used to select sample in East &

Central India region, which was selected on the basis of target market.

The identification of the sample size was done on the basis of judgment sampling and

convenience sampling. Sample size selected was 37.

32

DATA COLLECTION METHOD

The data are basically classified into two broad categories:

Primary data (data collected by means of direct mail, personal interview, direct contact,

questionnaire, etc.)

The primary data was collected to fulfill the objective of the project. The data was

collected through questionnaire and personal interviews with the respective head of the

sponge iron company.

Secondary data (data collected from secondary sources such as census, trade

publications, consumer panels, internet, etc)

The secondary data was collected to create a database for carrying out the research

work. The objective of the project was to find out the existing customers of subsidiary

and similar products (such as electrical heating systems & gas heating system). The

data was collected from the newsletters that are published by governmental and non-

governmental organizations, websites, visiting the libraries.

33

CHAPTER 7

RESEARCH ANALYSIS AND FINDINGS

The survey is carried out in Orissa and Chattisgarh. The analysis has shown that most

of the sponge iron industries are located in Orissa area. This area has availability of raw

materials, which are used for the manufacturing of Sponge Iron. The plant capacities

varied from 50 TPD (Tones per Day) to 500 TPD.

Most of the Sponge Iron manufacturing plants are using power sourced from the state

electricity board which is expensive. The cost of electricity accounts for 30% of the

manufacturing cost of sponge iron. Most of the plants have DG sets as standby source

of power as there is a minimum power cut of 2-3 hours daily. Some of the plants were

using other sources of electricity such as captive power plant and cogeneration plants.

The waste heat recovery and power generation system is very well accepted by the

sponge iron industry because of its state-of-the-art technology and high pay back period

although the initial cost is high. Since the system is especially designed for sponge iron

industry, the feasibility is very high and hence it has tremendous potential.

Almost all of the sponge iron manufacturing plants are currently wasting all the flue

gases which are produced in the process due to lack of awareness of the waste heat

recovery and power generation systems. The heat available from these waste gases has

tremendous potential of producing electricity, which is exhausted without utilization.

Different tabulations and graphs are made for the data collected during field survey.

The sample size is 37.

34

Have you heard the name of the company Transparent Energy Systems Pvt. Ltd.?

Yes No

Abs. 2 35

Percent 5 95

This question was aimed to know whether the companies in the area of research had

heard about the company TESPL or not. This is because TESPL is a growing company

in the field of Waste Heat Recovery Systems. The response was not so overwhelming

as people in this region were not aware about this company and its products and

services.

35

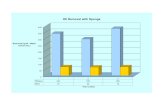

SOURCE OF POWER USED RESPONSE

GRID (STATE ELECT.) 25

CAPTIVE POWER PLANT 12

TOTAL SAMPLE SIZE 37

The above graph shows that maximum numbers of sponge iron companies are using

power from the grid which indicates that the power can be generated from the waste

gases and it will immensely increase the profitability of the companies, thereby

indicating tremendous market potential for the system.

36

LOCATION NO. OF PLANTS

ORISSA 32

CHATTISGARH 5

TOTAL SAMPLE SIZE 37

37

FEASIBILITY RESPONSE

HIGHLY FEASIBLE 29

SOMEWHAT FEASIBLE 3

NOT FEASIBLE 1

CAN’T SAY 4

TOTAL SAMPLE SIZE 37

The above graph shows that our waste heat recovery and power generation system is

highly feasible in most of the sponge iron companies which indicates there is large

potential for our system.

38

WATER AVAILABILITY RESPONSE

MORE THAN SUFFICIENT 24

SUFFICIENT 5

NOT SUFFICIENT 3

SCARCE 5

TOTAL SAMPLE SIZE 37

The above graph shows that most of the sponge iron companies have sufficient water

which indicates that our waste heat recovery and power system can be implemented at

lower cost.

39

The above graph shows that most of the respondents were attracted to the high pay

pack period of the system. Although the initial cost is high, the rapid pay-back period

makes it commercially very attractive.

* The no. of respondents for this graph is only 25 as 12 plants had either already

installed the Waste Heat Recovery System or were in the process of installing it.

40

The above graph shows that the waste heat recovery and power generation system has

created much interest among the sponge iron manufacturers. The power that can be

generated from the waste gases will immensely increase the profitability of the sponge

iron companies thereby indicating tremendous market potential for the system.

41

CHAPTER 8

CONCLUSION

After analyzing the data collected in field research following conclusions are made.

1. Almost all of the sponge iron manufacturing plants are currently wasting all the

flue gases which are produced in the process due to lack of awareness of waste

heat recovery and power generation systems. The heat available from these

waste gases has tremendous potential of producing electricity, which is

exhausted without utilization. The energy thus produced will be available

absolutely free of cost since the system utilizes energy which is exhausted into

the atmosphere and wasted.

2. In addition to producing electricity, the waste heat recovery and power

generation saves a lot of water, which can be put to other productive use. In

areas, which face scarcity of water, this system can prove to be a boon.

3. The system helps to reduce the dust content of the exhaust gases thereby

facilitating pollution control and eco-conservation. Industries using this kind of

waste heat recovery and power generation system can avail the benefits of

carbon credits through carbon trading.

4. The heat available for recovery from exhaust waste gases is of sufficient

temperature and quantity which makes the system highly feasible.

5. Hence the project proves that the waste heat recovery and power generation

system has immense market potential in the sponge iron industry in East India

region.

42

CHAPTER 9

RECOMMENDATIONS

From the analysis and conclusion it is clear that the waste heat recovery and power

generation system has good scope in East and Central India region. The market for the

system is very large and profitable in this region; hence it is essential to target the

particular region.

As Transparent Energy Systems Pvt. Ltd are technologically sound but are not known

throughout India, hence intensive corporate brand promotion campaigns should be

carried out in order to develop confidence amongst the industrial buyers.

It is suggested that the company should arrange awareness programs regarding benefits

of the waste heat recovery and power generation system. The company should organize

some exhibitions introducing their product. Also, they can arrange demonstrations to

the target customers explaining the percentage saved in energy cost and other benefits

of using the system.

Advertising the system in leading industrial magazines and journals can facilitate the

awareness program

Sponsoring national level awards related to engineering and design will prove

beneficial in building the brand name of the company. Sponsoring seminars and

conferences related to energy sector can also be effective.

For first installation of Waste Heat Recovery System in Sponge Iron industry,

Transparent Energy Systems should provide financing facilities and other monetary

concessions in order to promote its product in other Sponge Iron industries.

43

CHAPTER 10

LIMITATIONS OF THE PROJECT

No project is ideal. In reality I came across different problems which act as limitations

of the project such as-

1) Some of the respondents did not give other relevant information which

was required for the project.

2) Non -availability of official data.

3) There was time constraint (2 months). Hence total no. of plant visits was

limited.

4) To keep the project cost minimum due to budget constraints

5) Transportation problems due to rainy season.

44

CHAPTER 11

BIBLIOGRAPHY

Marketing Management

Philip Kotler

12th Edition

Thermal Engineering

S.Domkundwar, Dr.C.P.Kothhandaraman, A.V. Donkundwar

Fifth Edition (Year 2000)

Marketing Research

G C Beri

Third Edition

Research Methodology

Dr. C M Kothari

Himalaya Publication

World Wide Web

www.osima.com

Brochures of Transparent Energy Systems Pvt. Ltd, Pune

45

CHAPTER 12

ANNEXURE

QUESTIONNAIRE DESIGN

The questionnaire was designed to get the technical information. Questions in the

questionnaire were close ended as well as open ended. Before going on the field the top

management approved the questionnaire.

The questionnaire on company’s letter head which was used for survey is attached with

this report.

46