059 LEAN CONSTRUCTION SUPPLY CHAIN-SCM &LPS

-

Upload

dr-fereidoun-dejahang -

Category

Engineering

-

view

41 -

download

0

Transcript of 059 LEAN CONSTRUCTION SUPPLY CHAIN-SCM &LPS

[email protected]://www.construction-productivity.co.uk

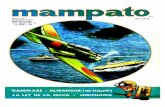

LEAN CONSTRUCTION LEAN CONSTRUCTION SUPPLY CHAIN SUPPLY CHAIN MANAGEMENT (SCM)MANAGEMENT (SCM) &&LAST PLANNER SYSTEM LAST PLANNER SYSTEM (LPS)(LPS)

LEAN CONSTRUCTION

Lean construction main objective is to maximizes value and reduces waste.

It applies specific techniques in an innovative project delivery approach.

It including:1. supply chain management, 2. Just-In-Time techniques.

Just-In-Time(JIT)

Supply ChainManagement

(SCM)

LeanConstruction

maximizes valuereduceswaste

Based on LeanManufacturing, of the Toyota

Production system

High productivity

LAST PLANNERSYSTEM

LEAN CONSTRUCTION

As well as the open sharing of information between all the parties involved in the production process.

Lean manufacturing is an outgrowth of the Toyota Production system.

Developed by Taichii Ohno in Toyota in the 1950s.

SUPPLY CHAIN MANAGEMENT The term supply chain, includes,

all the activities that lead a high quality product.

Customer satisfaction comes from a good service or high quality product such as:

materialsinformation

SUPPLY CHAIN MANAGEMENT funds People etc. Some researchers argue that the cost of a

product or service will increase of up to 10% percent because of poor supply chain design.

SUPPLY CHAIN MANAGEMENT

Supply Chain Management (SCM) analyzes the impact of design work on the construction process.

It enables much better project planning and management.

Through SCM, all parties are kept aware of important determinants such as:

SUPPLY CHAIN MANAGEMENT commitments schedules A high level of team work and corporation

that can: Source, produce and deliver products with

minimal lead-time and expense.

SUPPLY CHAIN MANAGEMENT

Construction industry does not emphasize enough on construction productivity and it’s determinants.

The industry measures performance in terms of the following:

completion on time completion within budget meeting construction codes

SUPPLY CHAIN MANAGEMENT

Contractors often hire subcontractors Sub contractors do not have contracts

with the owner Poor supply chain Sometimes client pays a high price to

contractor, however, the subcontractor may still have to work with inadequate budgets.

Often compromising quality as a result.

SUPPLY CHAIN MANAGEMENT

Communication tends to be via the contract, and is limited.

Innovation moves slowly in construction.

Sometimes there is a complete lack on innovation.

Few large companies, and almost no small companies have implemented the concept of a high quality product or service.

SUPPLY CHAIN MANAGEMENT There is no desire to have a productivity

manager. The traditional approach is to depend on

the experienced staff to run projects efficiently.

Such staff are rarely if ever trained in optimization techniques.

LAST PLANNER SYSTEM

The Last Planner System (LPS)-for small firms, improves both design and construction schedule/ programme predictability.

Work completed always on time. It is a system of inter-related

elements.

LAST PLANNER SYSTEM Full benefits come when all are

implemented together. Based on simple paper forms, it can be

administered using Post-it notes, paper, pencil, eraser and photocopier.

A spreadsheet can help.

LAST PLANNER SYSTEM

LPS begins with collaborative scheduling/programming engaging the main project suppliers from the start.

Risk analysis ensures that float is built in where it will best protect programme integrity and predictability.

Where appropriate the process can be used for programme compression too.

LAST PLANNER SYSTEM

LAST PLANNER SYSTEM

A key part of the continual improvement process is a study of the reasons why tasks promised in the WWP are delivered late.

The following chart shows typical reasons:

Figure 4: example of a reasons Pareto chart

LAST PLANNER SYSTEM

LAST PLANNER SYSTEM

Differences between Lean Construction approach and PMI approach

Lean Construction Exam questions.

LAST PLANNER SYSTEM

PROMISEPRODUCE

DECLAREDELIVERY

& ASSURE

ODECLARE

COMPLETE

REQUESTCLARIFY

&NEGOTIATECONDITION OFSATISFACTION

![gguo...ò ' ! LPS LBP LPS Bacteria LPS mCD 14 MONOCYTE TNF-A mCD14 ± f_f[jZggucj_p_ilhjfZdjhnZ]h\ - ©magZ_lªebihihebkZoZjb^ EIK ò ' ! LPS LBP LPS Bacteria LPS LBP LPS mCD 14 …](https://static.fdocuments.net/doc/165x107/60e7d4891f692c03dd4a8287/-lps-lbp-lps-bacteria-lps-mcd-14-monocyte-tnf-a-mcd14-ffjzggucjpilhjfzdjhnzh.jpg)