05 AC800M Hardware - RevC

-

Upload

gsanchez57 -

Category

Documents

-

view

1.695 -

download

18

Transcript of 05 AC800M Hardware - RevC

800xA Minerals Training

Chapter 5 - 1

Chapter 5 AC 800M Hardware

TABLE OF CONTENTS Chapter 5 AC 800M Hardware...................................................................................................................................................... 1

5.1 General Information............................................................................................................................................................. 3 5.1.1 Objectives ..................................................................................................................................................................... 3 5.1.2 Legend .......................................................................................................................................................................... 3 5.1.3 Reference Documentation............................................................................................................................................. 3

5.2 Overview AC 800M Hardware............................................................................................................................................ 4 5.3 Central Processing Unit ....................................................................................................................................................... 5

5.3.1 Components .................................................................................................................................................................. 5 5.3.2 Different Processor Units.............................................................................................................................................. 6 5.3.3 Start Modes................................................................................................................................................................... 7 5.3.4 Battery .......................................................................................................................................................................... 8 5.3.5 AC 800M Communication Ports .................................................................................................................................. 9 5.3.6 AC 800M High Integrity Controller ........................................................................................................................... 10

5.4 Communication Interface Units......................................................................................................................................... 11 5.4.1 Overview..................................................................................................................................................................... 11 5.4.2 Communication Exchange Bus - CEX Bus ................................................................................................................ 12

5.5 Input / Output Modules...................................................................................................................................................... 13 5.5.1 Range of ABB I/O Modules ....................................................................................................................................... 13 5.5.2 I/O Connection Possibilities ....................................................................................................................................... 14 5.5.3 S800 I/O Connected with ModuleBus ........................................................................................................................ 15 5.5.4 S800 I/O Connected with PROFIBUS........................................................................................................................ 16 5.5.5 Limitations of CI801................................................................................................................................................... 17 5.5.6 MTU – Module Terminal Unit for S800 I/O .............................................................................................................. 17

5.6 Hardware Redundancy....................................................................................................................................................... 18 5.6.1 Redundant Processor Unit - PM861/PM864/PM865.................................................................................................. 18 5.6.2 Controller and I/O Redundancy .................................................................................................................................. 19 5.6.3 Redundant ModuleBus I/O Connections .................................................................................................................... 20 5.6.4 Redundant PROFIBUS I/O Connections.................................................................................................................... 21

5.7 Hardware Configuration .................................................................................................................................................... 22 5.7.1 Configuration Steps .................................................................................................................................................... 22 5.7.2 Adding a Controller CPU ........................................................................................................................................... 23 5.7.3 Adding a Communication Interface Module............................................................................................................... 24 5.7.4 Hardware Libraries ..................................................................................................................................................... 24 5.7.5 Adding S800 I/O on ModuleBus ................................................................................................................................ 26 5.7.6 Adding S800 I/O on PROFIBUS................................................................................................................................ 27 5.7.7 Hierarchical Dot Notation........................................................................................................................................... 28 5.7.8 Settings of I/O Units ................................................................................................................................................... 29 5.7.9 Adding Compact Flash ............................................................................................................................................... 30

5.8 Communication to AC800M Controller ............................................................................................................................ 31 5.8.1 How to Use the IPConfig Utility ................................................................................................................................ 31 5.8.2 How to Configure the IP Address............................................................................................................................... 34 5.8.3 How to Download the Firmware................................................................................................................................. 35

5.9 Application Download....................................................................................................................................................... 37 5.9.1 General........................................................................................................................................................................ 37 5.9.2 Restart Options ........................................................................................................................................................... 37 5.9.3 Download.................................................................................................................................................................... 38 5.9.4 Difference Report ....................................................................................................................................................... 39 5.9.5 Re-Authentication....................................................................................................................................................... 40

5.10 Online Functions.............................................................................................................................................................. 41 5.10.1 General...................................................................................................................................................................... 41

05 AC800M Hardware - RevC.doc

Chapter 5 - 2

5.10.2 Status of I/O-Signals ................................................................................................................................................. 41 5.10.3 Forcing ...................................................................................................................................................................... 42

5.11 Test Mode & SoftController ............................................................................................................................................ 43 5.11.1 Test Mode ................................................................................................................................................................. 43 5.11.2 How to use the SoftController................................................................................................................................... 43

800xA Minerals Training

Chapter 5 - 3

5.1 General Information

5.1.1 Objectives

Upon completion of this chapter, you will be able to:

• Describe the AC 800M hardware components

• Set up communication to controller AC 800M

• Upgrade the controller firmware

• Configure the hardware in the Control Project

• Download and test hardware in online mode

5.1.2 Legend

> Indicates when you go from one menu to a sub-menu

Italic Indicates object and file names

“ “ Indicates dialog box buttons, tabs, menus etc.

Bold Indicates important topics

Indicates start/explanation of student activity

5.1.3 Reference Documentation

3BSE036351 Industrial IT 800xA – Control and I/O AC 800M Controller - Hardware and Operation

3BSE035980 Industrial IT 800xA – Control and I/O Basic Control Software – Introduction and Configuration

3BSE020923 Industrial IT 800xA – Control and I/O S800 I/O – General Information and Installation

3BSE020924 Industrial IT 800xA – Control and I/O S800 I/O – Modules and Termination Units

05 AC800M Hardware - RevC.doc

Chapter 5 - 4

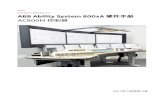

5.2 Overview AC 800M Hardware

The AC 800M controller consists of a selection of units mounted on horizontal DIN-rails, which can be housed within an enclosure. The majority of units consist of a base mounting plate and removable cover attached with screws.

The hardware units that form the AC 800M controller are:

• Central Processor Unit (CPU)

• Communication interface modules for different protocols

• S800 I/O modules

• Power supply modules

RS-232 channels

Optional up to 12 Communication modules

Redundant Ethernet

CPU S800 I/O

Various I/O systems can be connected to the AC 800M controller, either directly (S800 I/O) or via PROFIBUS or FOUNDATION Fieldbus.

800xA Minerals Training

Chapter 5 - 5

5.3 Central Processing Unit

5.3.1 Components

The CPU consists of a base plate TP830 and a replaceable processor module PM8xx with various speed and memory combinations.

The base plate TP830 carries the majority of the connections to processor, the power supplies and communication interfaces, as well as to the external buses.

A Compact Flash (CF) can be inserted to the card slot located at the front of AC 800M controllers. The card will be activated and read after a long controller reset (or power failure) and your application(s) can be loaded into the controller without performing an application download from a Control Builder station.

CPU Baseplate

Fuses for Modulebusand CEX-bus

05 AC800M Hardware - RevC.doc

Chapter 5 - 6

5.3.2 Different Processor Units

The key differences between the different CPUs are memory, working frequency and redundancy.

PM856

8MB24 MHz

PM851

8MB24 MHz

PM865Redundant

32MB96 MHz

SIL2

PM864Redundant

32MB96 MHz

PM861Redundant

16MB48 MHz

PM860

8MB48 MHz

Unit Description On-line replacement

Redundancy

PM851 24 MHz (48MHz for communication) / 8 Mbytes RAM 1 Ethernet port, 1 Serial port and 1 tool port. Application speed is half of PM860. Maximum one CEX bus module.

No No

PM856

24 MHz (48MHz for communication) / 8 Mbytes RAM 2 Ethernet ports, 1 Serial port and 1 tool port. Application speed is half of PM860.

No No

PM860 48 MHz / 8 Mbytes RAM

2 Ethernet ports, 1 Serial port and 1 tool port.

No No

PM861 48 Mhz / 16 Mbytes RAM 2 Ethernet ports, 1 Serial port and 1 tool port. Singular or redundant.

Yes Yes

PM861A Same as PM861 but can use redundant communication unit CI854A, CI860 and BC810.

Yes Yes

PM864 96 Mhz / 32 Mbytes RAM 2 Ethernet ports, 1 Serial port and 1 tool port. Singular or redundant. PM864 is 50% faster than PM861 in executing an application.

Yes Yes

PM864A Same as PM864 but can use redundant communication unit CI854A, CI860 and BC810.

Yes Yes

PM865 (PA/HI) 96 Mhz / 32 Mbytes RAM 2 Ethernet ports, 1 Serial port and 1 tool port. PM865 can be used in an AC 800M High Integrity system.

Yes Yes

800xA Minerals Training

Chapter 5 - 7

5.3.3 Start Modes

The controller may be started with the following start modes:

Mode Invoked by Description Warm Init Power Off/On with a

battery backed up CPU Applications restart with retain values.

Cold Init Press Init < 2.5 s Applications restart with cold retain values.

Reset Press Init > 3 s or until Run LED flashes

Applications are deleted in controller.

05 AC800M Hardware - RevC.doc

Chapter 5 - 8

5.3.4 Battery

The memory is backed up by an internal or an external battery. You should mount the battery when the CPU is up and running with a loaded application.

Internal External

The backup time varies depending on CPU type and battery types.

NOTE! A Compact Flash card can be used for non-volatile storage of application and data.

CPU Type Internal Battery min time (hours)

External Battery min time (weeks)

PM851/PM856/PM860 48 4

PM861 36 4

PM864 36 3

PM861A 118 12

PM864A 235 24

PM865 HI 235 24

PM865 PA 235 24

800xA Minerals Training

Chapter 5 - 9

5.3.5 AC 800M Communication Ports

Detailed description of the communication ports of the CPU:

• Two built-in Ethernet ports (IEEE 802.3, 10BaseT with TCP/IP): CN1 CN2 used for redundancy

• Two built-in RS-232 serial ports: COM3 with modem support for several protocols COM4 intended as tool port for Control Builder

• Built-in ModuleBus for optical or electrical connection to I/O communication

• Built-in CEX-bus (Communication Extended Bus) for external communication modules

NOTE! In a configuration with redundant CPUs, COM3 and the electrical ModuleBus cannot be used.

RCU link connection

Communication Expansion

CEX - busCPU

S800I/ O ’ s on the Electrical ModuleBus

Ethernet ports COM 3-4 portsFiber opticaleModuleBus

05 AC800M Hardware - RevC.doc

Chapter 5 - 10

5.3.6 AC 800M High Integrity Controller

AC 800M can easily be configured for usage in safety critical applications. The main components of such a system are PM865, SM810, SS823 and the S800 I/O High Integrity system, running a High Integrity version of Control Software.

The PM865 processor unit has higher HW fault tolerance, compared to PM864. The added functionality on PM865 includes:

• Double over voltage protection on internal voltages

• Additional watchdog timer updated with data from SM810

• Increased oscillator supervision

• Support for S800 I/O High Integrity system

• Increased system diagnostic and online self tests

The main function of the SM810 is to act as a monitor for the HW and SW execution of PM865 and these two modules together are a SIL2 compliant system according to IEC61508. The SM810 is running a SIL2 certified operating system and have a very high degree of self-diagnostic.

800xA Minerals Training

Chapter 5 - 11

5.4 Communication Interface Units

5.4.1 Overview

A number of communication modules can be connected to the CEX bus.

RS

232

CI8

53P

RO

FIB

US

DP

CI8

54A

MB

300

CI8

55

S10

0 I/O

CI8

56

INS

UM

CI8

57

Driv

eBus

CI8

58

FF H

SE

CI8

60

PM8x

x

TRIO

I/O

CI8

62

Sat

t I/O

CI8

65

Mod

bus

TCP

CI8

67

The table below is a summary of the interfaces (for details refer to hardware manual):

Unit Description On-line replacement

Redundancy

CI851 PROFIBUS DP-V0 communication interface unit.

Only to use with S200 I/O.

No No

CI853 RS-232C serial communication interface unit. No No

CI854 PROFIBUS DP-V1 communication interface unit.

Redundant Profibus cabling possible.

No No

CI854A PROFIBUS DP-V1 communication interface unit.

Redundant Profibus cabling and redundant interface cards.

Yes Yes

CI855 MasterBus 300 communication interface unit for the AC 800M. Yes No

CI856 S100 I/O system communication interface unit. Up to five S100 I/O racks can be connected to one CI856 where each I/O rack can hold up to 20 I/O boards.

Yes No

CI857 INSUM communication interface unit. Yes No

CI858 Communication interface for ABB Drives using DriveBus No No

CI860 Fieldbus Foundation HSE communication interface unit.

Not possible to use in AC800M HI.

Yes No

CI865 Communication interface unit for older Satt I/O systems. Yes No

CI867 Provides communication with Modbus TCP via Ethernet. Yes No

05 AC800M Hardware - RevC.doc

Chapter 5 - 12

5.4.2 Communication Exchange Bus - CEX Bus

TB850

TK850 with DB25P and TB851or

TB850

TK850 with DB25P and TB851or

• Up to 12 communication units can be placed on the CEX bus

• The CEX-bus must be terminated if a communication unit is connected. A CEX-bus termination is delivered with the CPU: TB850 (male) or TB851 (female).

• An extension cable TK850 with connector DB25P with metal housing and a length of 0.7 meter (2.3’) can be used for extending the CEX bus to a second DIN rail.

800xA Minerals Training

Chapter 5 - 13

5.5 Input / Output Modules

5.5.1 Range of ABB I/O Modules

The following I/O types can be connected to an AC 800M system:

• S800 modular I/O

• S800 modular I/O with intrinsic safety (IS)

• S800L I/O This is a compact I/O with an integrated I/O and terminal unit. This I/O cannot be replaced on-line.

• S200 I/O This I/O must be connected through communication module CI865

• S900 I/O This I/O must be connected through a CI920 PROFIBUS module. The I/O is suitable for use in hazardous areas.

• S100 I/O This I/O must be connected through communication module CI856

05 AC800M Hardware - RevC.doc

Chapter 5 - 14

5.5.2 I/O Connection Possibilities

I/O units are connected in two ways:

• ModuleBus (electrical or optical)

• PROFIBUS DP

An I/O cluster consists of one CI830/CI801 or TB820 and a number of I/O modules. Max. 12 I/O modules can be included in one I/O cluster.

S900 I/O can only be connected through PROFIBUS DP.

The PROFIBUS slave CI830/CI801 can be also be supplied with an adapter TB810 to extend the ModuleBus by optical cable.

NOTE! CI830 is replaced by CI801 to support the HART protocol.

800xA Minerals Training

Chapter 5 - 15

5.5.3 S800 I/O Connected with ModuleBus

The ModuleBus interface is used for handling local S800 I/O on the AC 800M controller. I/O units connected to ModuleBus are organized into clusters. The ModuleBus in the AC 800M controller consists of:

• Electrical ModuleBus (base cluster) – not extensible and maximum of twelve S800 I/O units

• Optical ModuleBus –maximum of seven TB820 cluster modems

• Max. 96 I/O modules

• 1-12* S800 I/O modules per cluster

Base cluster

Modulebusextension

max. 2.5 meters

I/O cluster 1TB820

Optical modem

TerminationTB807

max. 15 or 200m

I/O cluster 2

Simplex

I/O cluster 3

Duplex

I/O cluster 4

max. 15 or 200m

The optical modem TB820 acts as an adapter from optical to electrical ModuleBus. A maximum of 7 optical modems can be connected to the CPU.

05 AC800M Hardware - RevC.doc

Chapter 5 - 16

5.5.4 S800 I/O Connected with PROFIBUS

The CI854 unit is the main PROFIBUS DP-V1 communication interface and it can be used to communicate with remote I/O or with actual PROFIBUS devices.

• Max. 24 I/O modules / I/O Station

• 1 base cluster

• 1-7 I/O cluster

• 1-12* S800 I/O modules per cluster *The memory size and bus load in the CI830/CI801 or TB820 limits the number of I/O modules per cluster

• Max. cluster length 2.5m (electrical ModuleBus)

Base cluster

CI801Profibus slave

CI854Profibus master

Max. 2.5 meters

I/O cluster 1

withTB810

I/O cluster 2

Simplex

I/O cluster 3

max 15 or 200m

Duplex

I/O cluster 4

max 15 or 200m

TB820Optical modem

NOTE! CI840 is the redundant version of CI801.

800xA Minerals Training

Chapter 5 - 17

5.5.5 Limitations of CI801

The maximum number of I/O modules you can connect to a station is 24 modules.

Due to the PROFIBUS-DPV1 specification it is not possible to always connect 24 I/O modules. The reason is that the S800 I/O system includes more data and user parameters than PROFIBUS-DPV1 can handle. The table below shows the maximum number of I/O modules that can be connected to one CI801.

NOTE! Refer to the manual: Fieldbus Communication Interface

PROFIBUS-DP/DPV1, 3BSE020926.

5.5.6 MTU – Module Terminal Unit for S800 I/O

The S800 I/O unit is attached to an MTU, Module Terminal Unit. A number of MTUs are available. They can however be divided into two major groups, depending on the physical layout:

• Compact / 1 connection per channel

• Extended / 3 connections per channel

Compact Extended NOTE! Mechanical key protection prevents wrong I/O module

type from being inserted.

05 AC800M Hardware - RevC.doc

Chapter 5 - 18

5.6 Hardware Redundancy

5.6.1 Redundant Processor Unit - PM861/PM864/PM865

In a system with redundant Processors, the controller contains two processor units, each including memory for system and application software. In a redundant system the two processor units are linked together with the RCU Link Cable (max 1 m).

One unit is acting as primary, the other is backup (hot stand-by). The primary processor unit controls the process. The backup stands by to take over in case of a fault in the primary. The primary CPU is always updating the backup CPU.

You can select late in your project if you need redundancy option.

Both CPUs are connected to the CEX bus and either of the two can control the communication interfaces. BC810 supports online replacement of the CPU baseplate without disturbing the CEX traffic.

In a redundant configuration an automatic switch-over from the Primary CPU to the Backup CPU occurs in the following situations, provided they are in synchronized state (DUAL LED is lit):

• Memory or other hardware error in the Primary CPU.

• Severe communication errors on the Control network, that is, loss of both network ports in the Primary CPU.

• Severe communication errors on the ModuleBus

NOTE! The changeover is done bumpless and in less than 10 ms.

RCU Link

800xA Minerals Training

Chapter 5 - 19

5.6.2 Controller and I/O Redundancy

Use of redundancy will reduce the maximum number of S800 channels. Each cluster may contain up to 12 single S800 I/O units or up to 6 redundant S800 I/O units.

Optical ModuleBusCable

RedundancyLink Cable

CEX -bus splitter BC810

Redundant PROFIBUS CICI854A

Redundant or SingularS800 I/O

Redundant S800 I/O as direct I/O

05 AC800M Hardware - RevC.doc

Chapter 5 - 20

5.6.3 Redundant ModuleBus I/O Connections

When you use redundant I/O module configuration, the maximum number of I/O modules in one cluster is 6 pairs.

800xA Minerals Training

Chapter 5 - 21

5.6.4 Redundant PROFIBUS I/O Connections

When you use redundant I/O module configuration, the maximum number of I/O modules in one cluster is 6 pairs.

• TU846 is used for Redundant I/O modules

• TU847 is used for non redundant I/O modules

• CI840 is connected to CI854 PROFIBUS master

TU846 or TU847

05 AC800M Hardware - RevC.doc

Chapter 5 - 22

5.7 Hardware Configuration

Hardware units are added to the tree structure in the Project Explorer representing physical hardware units. Some units contain sub units, such as serial channels, that are automatically created.

As you can see on the example of a hardware configuration above, there are 4 I/O modules connected to ModuleBus and 5 I/O modules connected to PROFIBUS.

5.7.1 Configuration Steps

To add a new hardware unit in the Project Explorer, proceed as follows:

1. Select the unit to which you want to add the new hardware unit.

2. With the unit selected, right-click on the unit and select “New unit”. A submenu listing possible hardware is displayed. Select the type of hardware you wish to add. If <New unit> is dimmed, the unit you have selected in step 1 may not contain any sub units, or the maximum number of sub units has been reached.

3. Select a position for the hardware unit in the dialog box displayed. The first available position is chosen by default. If another position is desired, click the list box to display available positions. Click “OK”.

4. The hardware unit is now added to the tree, and the name of the hardware unit, as well as its position, is displayed next to the icon of the hardware unit. The icons look different depending on which type of unit was added.

800xA Minerals Training

Chapter 5 - 23

5.7.2 Adding a Controller CPU

In the Project Explorer, right click on Controllers and choose “New Controller”.

Then choose the new CPU type that you wish to insert.

ModuleBus Scan Time

Double-click on the “ModuleBus” icon to open the editor. The Scan Cycle Time is the fastest general interval time used by the CPU to do an I/O copy of all I/O modules.

The parameter “Scan Cycle Time” for the cycle time of the ModuleBus can be set in the range 0...100 ms. Default setting is 0 (as fast as possible) and can load the CPU significantly. The minimum scan time in practice will be 6 ms.

NOTE! It is recommended to change the default settings in order to reduce the CPU load.

05 AC800M Hardware - RevC.doc

Chapter 5 - 24

5.7.3 Adding a Communication Interface Module

Open the just inserted controller structure, right click on Hardware AC 800M and choose “Insert Unit”.

Choose the communication interface module that you want and click “Insert”

Note that you are not able to insert any other communication unit by default. To do this, we need first to connect the required hardware libraries.

5.7.4 Hardware Libraries

Hardware types are organized and installed as libraries in Control Builder. The library containing the hardware type has to be connected to the controller, to make it possible to add the hardware type (unit) to the controller.

First right click and select “Insert Library” to insert the library to the Control project.

800xA Minerals Training

Chapter 5 - 25

Then choose the relevant hardware library and click “Insert”.

The library needs then to be connected to the controller. Select Connected Libraries, right click and choose “Connect Library”.

NOTE! An overview of the available hardware libraries is shown in chapter “Libraries”.

05 AC800M Hardware - RevC.doc

Chapter 5 - 26

5.7.5 Adding S800 I/O on ModuleBus

Open the just inserted controller structure, right click on ModuleBus and choose “Insert Unit”.

Then choose the appropriate S800 I/O and the position (slot).

800xA Minerals Training

Chapter 5 - 27

5.7.6 Adding S800 I/O on PROFIBUS

Open the just inserted controller structure, right click on the inserted communication interface module such as a CI851, choose “Insert Unit”.

First insert the PROFIBUS slave (CI830 / CI801 / CI840).

NOTE! Position value must be consistent with the address

settings of the switches on CI830 board.

Then insert the desired I/O module type.

05 AC800M Hardware - RevC.doc

Chapter 5 - 28

5.7.7 Hierarchical Dot Notation

The hardware address of a hardware unit is composed from the hardware tree position numbers of the unit and its parent units, described from left to right and separated by dots. For example channel 1 on the I/O unit DI810 has the controller address:

Controller_1.0.11.3.1

Channel 1

Note that the position number for the CI851 is the physical location on the CEX-bus, while the position for the CI830 is the PROFIBUS node number (set by switches).

Note that an optical modem TB820 is not visible in the Project Explorer. The I/O cluster is only indicated by the position of the I/O modules e.g. I/O modules in cluster number 3 have positions from 301 to 312.

800xA Minerals Training

Chapter 5 - 29

5.7.8 Settings of I/O Units

Scaling

For analog inputs and outputs, you can specify the physical minimum and maximum values corresponding to the signal range 0-100 %. You can also assign a physical unit to your variable. These settings are accessible in code from the RealIO data type.

Preset Values/OSP/ISP

You can specify what value to assign to an I/O channel in case the I/O unit loses communication with the CPU or PROFIBUS slave. The choices are: Keep last value, Reset output/input or Assign OSP/ISP value. The last is a preset value, specified in the editor for the I/O unit. The degree of configuration you can make for a particular I/O channel depends on the type of I/O unit.

Signal Range

This setting specifies the electrical signal range; 0-20 mA, 0-10 V etc.

05 AC800M Hardware - RevC.doc

Chapter 5 - 30

5.7.9 Adding Compact Flash

Expand the Controllers structure and right click the CF Reader item. Select “Insert Unit” from the context menu and insert the CF Card item.

NOTE! You must connect an external Compact Flash writer to

your Engineering station where Control Builder is loaded (normally connected to the USB port).

Make sure your project is in offline mode and insert a Compact Flash card in the Writer slot. Right-click on the controller item and select “Compact Flash” from the context-menu to pick the writer.

Click “OK” to write the application to the Compact Flash card.

For a redundant CPU configuration, you need to write the same application twice (two CF cards, one in each CPU). Copy (in Windows Explorer) the downloaded application (two folders) from the CF card and paste them temporarily on your local disk. Insert the next memory card into the writer and drag your two folders from the hard disk and drop them on the new CF memory card.

NOTE! Backup of cold retain values to Compact Flash is not supported for redundant CPU’s.

800xA Minerals Training

Chapter 5 - 31

5.8 Communication to AC800M Controller

All controllers delivered from the factory have the same IP address. You must change the IP address to an address, which is available in your own network.

5.8.1 How to Use the IPConfig Utility

Use the tool IPConfig to establish contact between the engineering station and the controller and change the IP address.

You can start the IPConfig tool by: Start | Programs | ABB Industrial IT 800xA | Engineering | Utilities | IPConfig

1. Connect your PC with the controller using a TK212 cable connected to serial port on your PC and to the toolport (COM4) on the AC 800M controller.

2. Choose the COM port on your PC by click on “Settings”

05 AC800M Hardware - RevC.doc

Chapter 5 - 32

3. Press “Connect”

The IPConfig status bar will change from Not Connected to Connecting.

4. Make a long (more than 3 seconds) Init of the controller, release the init button when the Run LED start to blink. After the system-reset button has been pushed it takes approximately 10s before IPConfig detects the system reset and the status bar changes to System reset detected waiting for controller start-up. If the connection fails, a message box will indicate Connect failed, Time-Out. The reason may be the following: - The serial cable is not connected correctly. - Too long time elapsed between clicking the Connect button and the system reset of the controller.

5. When IPConfig is connected the status bar will change to Connected.

6. To set the submask, you must enter advanced mode by choose “Settings” and choose the “Advanced mode”.

800xA Minerals Training

Chapter 5 - 33

7. Modify IP address, press “Set IP” and the text boxes will show the current controller IP address settings.

When the new IP address has been stored successfully the status bar will show “Controller IP configuration updated”.

NOTE! Do not use IPConfig for a controller when an application is running in it. IPConfig will delete every application in the controller.

Ethernet addresses are kept in the flash memory. Always close IPConfig when you are done with it, because IPConfig uses the tool port (Com4) and the rest of the CPUs channels will be locked.

05 AC800M Hardware - RevC.doc

Chapter 5 - 34

5.8.2 How to Configure the IP Address

After setting the controller’s IP address with the IP-config tool, you must do the IP address settings of the controller in CBM in two steps:

1. Right click the Controller, choose “Properties > System Identity” and then set the desired IP address of the controller.

The System Identity is the network address of the selected controller. The network address is shown beside the controller icon in the Project Explorer tree.

NOTE! The default address is 172.16.0.0

2. Open the controller’s PM8xx/TP830 and then double click the first Ethernet.

800xA Minerals Training

Chapter 5 - 35

This will open a new window, click on the “Settings” tab, then set the same IP address and subnet mask as you have set with the IPConfig tool.

NOTE! The system identity should normally correspond to the

setting for Ethernet 1 on the AC800M.

5.8.3 How to Download the Firmware

The upgrade of the CPU firmware can be done either from the serial line connected to the toolport (COM4) on your controller or over Ethernet. The Serial Firmware Upgrade tool is intended to be used as a last resort, if the normal firmware upgrade procedure, for some reason, fails.

The most comfortable way is to use the Control Builder, because you will be able to compare the current firmware in the controller with the firmware on the hard disk.

1. Select “Remote System”.

05 AC800M Hardware - RevC.doc

Chapter 5 - 36

2. Press “Show Firmware Information”.

3. Compare the firmware on disk with the firmware in the controller

4. Select the firmware which has to be downloaded and press “Download Firmware”.

Note that once the firmware has been upgraded to version 5.0, further controller upgrades and system upgrades can be done online without shutting down the whole system.

800xA Minerals Training

Chapter 5 - 37

5.9 Application Download

5.9.1 General

During a download, the code that has been written is checked and compiled. The controller receives the compiled application and begins executing it immediately.

Once your application has been compiled, you can:

• Download the application and go Online. This updates the application in the controller.

• Go online without download of the application. Useful when, for example, monitoring values in the controller without disturbing the controller.

A version analysis of the applications is made when you download. The analysis results are used to determine if and how applications shall be updated to new versions in the controllers.

5.9.2 Restart Options

When the system restarts, variables with No Retain, Retain and Cold Retain attributes will behave differently. It will also matter if the system performs a warm or a cold restart.

WARM RESTART

At a warm restart, variables with the attribute <retain> or <coldretain> are protected by the battery during restart. During the time that the controller is stopped, all output I/Os will keep their last value.

COLD RESTART

At a cold restart, variables with the attribute <coldretain> keep their values, since they are stored on the hard disk. Variables without the attribute <coldretain> lose their values. During the stop time, all output I/Os will keep their last safe state/OSP values.

INIT RESTART

At a Init restart, variables with the attribute <coldretain> or <retain> are returned to the initial value

05 AC800M Hardware - RevC.doc

Chapter 5 - 38

5.9.3 Download

Select “Tools > Download Project and go Online” in the CBM.

If changes have been made to one or several applications in Offline mode, the version analysis detects it. You can then decide how to restart the changed applications.

Independent of how you restart the applications, the changed application parts are downloaded to the controllers. The controller will stop the applications and restart with the new and changed application.

NOTE! Following download the last message should be: You are now Online!

800xA Minerals Training

Chapter 5 - 39

5.9.4 Difference Report

Just before the download to controllers, the system will open a ‘Difference Report’ window, which shows the differences between the applications on disk & applications in the controllers. At this time you may decide to continue or to cancel the download.

The purpose of the difference report is validation of configuration changes.

You may disable the difference report function in project context menu “Settings > Difference Report”.

05 AC800M Hardware - RevC.doc

Chapter 5 - 40

5.9.5 Re-Authentication

If the Re-authenticate function is enabled, the user will be asked to enter user name and password, before download is completed.

You may disable this function by setting the corresponding system variable to “False”.

800xA Minerals Training

Chapter 5 - 41

5.10 Online Functions

5.10.1 General

In Online mode the Control Builder is connected to one or more controllers and offers many diagnostic and inspection features when online to the controller. You can:

• View the executing code dynamically

• Force inputs and outputs at the I/O modules

• Rescale analogue input and output channels

• Change values of variables

• Inspect values of variables

To enter Online mode, go to the tool bar menu of the Control Builder, click on “Tools” and then click on “Online”.

5.10.2 Status of I/O-Signals

Use the status tab of the hardware configuration editor, in online mode, for dynamic online display of I/O channel values and forcing. I/O channel values are updated once every second.

NOTE! The tab is available in Offline mode, but is not editable.

Underflow, overflow, channel and unit errors in online mode are indicated in the Channel value cell by the following icons:

Signal Errors underflow The signal is below the range.

overflow The signal is above the range.

Hardware Errors channel error The channel can have under range, power-up or field power errors.

Unit error The unit can be missing or of the wrong type.

05 AC800M Hardware - RevC.doc

Chapter 5 - 42

5.10.3 Forcing

Forcing of I/O is possible in online mode. Check a check box in the Forced column and then type in a value in the Channel value column for outputs and in the Variable value column for inputs. This value overrides the values in each of those columns.

When a channel is forced all copying between the I/O value and the application value is stopped. The forced value is different for inputs and outputs.

• For inputs the forcing changes the variable value to the application.

• For outputs the forcing changes the physical I/O channel value.

NOTE! The background of the forced cell changes to yellow to

indicate forcing.

Forcing is performed in the hardware configuration editor under the “Status” tab or the POU editor.

Normally only channels with variable connections to application programs can be forced. However, if no variable is connected you have to change the parameter Copy Unconnected Channels under the “Settings” tab for the current controller to get a status update.

800xA Minerals Training

Chapter 5 - 43

5.11 Test Mode & SoftController

5.11.1 Test Mode

Without downloading to a real controller or a SoftController, you may test your application by using the test mode. In CBM, select “Tools > Test mode”.

5.11.2 How to use the SoftController

You may also test your application and even your hardware by downloading to a SoftController running on your PC. It is also possible to use the SoftController for communication purposes, for example, COMLI or MODBUS.

1. Set the controller’s system identity you want to test to your PC’s IP address:2 (such as 172.16.0.1:2).

NOTE! It is also possible to use the loop back adapter address as 127.0.0.1:2.

2. Right click the controller, select “Properties > Simulate Hardware”

05 AC800M Hardware - RevC.doc

Chapter 5 - 44

3. Start the SoftController by double-click the icon on the desktop or choose the path below:

4. Click “Start”.

5. Choose “Download project and Go online”.