05-5 SOP - Hydraulic Fracturing.pdf

-

Upload

hendrie-nmc -

Category

Documents

-

view

216 -

download

0

Transcript of 05-5 SOP - Hydraulic Fracturing.pdf

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

1/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 1 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

STANDARD OPERATING PROCEDURE

Perawatan Sumur dan Kerja-Ulang Khusus Pengasaman, Fracturing dan Perforasi

1. Pengasaman

Membuat rencana penempatan peralatan untuk masing-masing lokasi dan mereview rencana tsb bersama-

sama supervisor rig dan perusahaan pengasaman sebelum membawa rig perawatan sumur dan peralatan pengasaman ke lokasi. Memastikan bahwa tata-letak peralatan sesuai dengan panduan penempatan.

Melakukan rapat keselamatan pra-kerja dan mereview program perawatan sumur dengan perusahaan

pengasaman dan staf rig perawatan sumur. Mereview Lembaran Data Keamanan Bahan (MSDS) untuk

bahan-bahan yang akan ditangani.

Memberitahu Bagian S&E, 24 jam sebelum melakukan pengasaman untuk pemasangan safety shower dan

alat pemadam api di lokasi.

Mengikuti Checklist keselamatan kerja dan kontrol kualitas dari JOB.

Mengikuti panduan dari perusahaan pengasaman untuk penanganan cairan yang mudah berkarat dan

mudah terbakar dengan aman.

1.2 Perekahan

Membuat rencana penempatan peralatan untuk masing-masing lokasi dan mereview rencana tsb bersama-sama supervisor rig dan perusahaan perekahan sebelum membawa rig perawatan sumur dan peralatan

perekahan ke lokasi. Memastikan bahwa tata-letak peralatan sesuai dengan panduan penempatan.

Mengadakan rapat keselamatan pra-kerja dan mereview program perawatan sumur dengan perusahaan

perawat sumur dan staf rig perawatan sumur.

Memberitahu Bagian S&E 24 jam sebelum melakukan pekerjaan untuk memasang safety shower dan alat

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

2/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 2 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

pemadam api ke lokasi.

Mengikuti checklist keselamtan kerja dan pengontrol kualitas JOB.

Mengikuti panduan perusahaan perekahan untuk penanganan cairan yang bisa menimbulkan karat dan

mudah terbakar secara aman

Catatan: Lampirkan copy dari SOP ini ke dalam masing-masing program kerja-ulang sumur.

1.3 Perforasi – Tubing Conveyed and Wireline Conveyed

Mengadakan rapat keselamatan pra-kerja dan mereview program perawatan sumur dengan perusahaan

perforasi dan staf rig perawatan sumur.

Mengikuti panduan perusahaan perforasi untuk penanganan bahan peledak secara aman

Mereview checklist pekerjaan perusahaan perawatan sumur sebelum dan selama JOB.

Pastikan ketinggian fluida 100 m di atas zona yang akan diperforasi. Lakukan pengecekan kedalaman

fluida sebelum memasang packer.

Setelah peledakan TCP gun, gun jangan dilepas dari tubing tanpa diskusi dan persetujuan tertulis dari

kepala engineering.

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

3/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 3 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

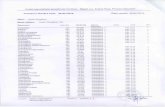

Fracturing Candidate Selection Check List

Well

Frac Candidate Rating

Additional Work Required To Frac Zone

Common Items to all zones Y/N Note Detail Action Required

Cement:

1 Condition of cement, above and below zone of interest

2 Top of cement

3 Any squeeze perforations in wellbore

4 Liner cemented or not

5 Thief zones or wash out present

Wellbore:

6 Evidence of casing damage or previous repair

7 Wellbore debris present that may affect frac

8 Well deviation at zone of interest9 Casing size & weight

10 Condition of casing above & below zone of interest

11 History of milling & drilling above & below zone of interest

12 Liner size & weight

13 Condition & location of liner

14 Sufficient blank casing for setting tools

15 Date of last perforation in zone of interest

16 Total area of perforations (min. 14.8 in.sq)

Reservoir:

17 Well location to faults

18 Well location to nearest wells

19 Shale present above & below zone of interest

20 Shale thickness above & below zone of interest

21 Reservoir pressure

22 Adequate injector support

23 Current production & estimate future production

Treatment:

24 Previous treatments

25 Screen out expected or not

26 Expected leak off (high/low)

27 Anticipated surface treating pressure

28 Target height

29 Lithology

30 Zone barriers present or not

31 Frac history of nearest wells

Surface:

32 Resident distance to wellsite

33 Wellsite adequate for W/O equipment

34 Adequate access road to wellsite

35 Wellhead & equipment condition

36 Wellhead size & rating

Lifting Equipment:

37 Lift equipment required following treatment

Definition of Rating:

1Recommended: normal operation

2Recommended: additional work required, low risk (ie. 'C' zone isolation)3Recommended: additional work required, medium risk and/or medium cost (ie.

repair bond above or below zone / upper casing leak)

4Recommended: additonal work required high risk and/or high cost (ie. casing

liner or high oil production in adjacent zones at risk of damage from operation)

5Not recommended: additional work required with high riskand/or high cost.

Equipment and/or services not available or under contract.

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

4/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 4 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Location :

Date :

Item Check

01. Compact Rig up, minimum iron used !

02. Safe, practical distance from wellhead !

03. Master valve properly installed on main line !

04. Pressure transducer at or near wellhead !

05. Lines properly staked, including bleed off and forced closure lines !

06. All iron should be flexible !

07. Check valve on each pump pretested before each job !

08. Check for sufficient suction hose and evaluate velocity per hose !

09. Check horsepower and plunger size of pumps on location !

10. Check flow monitoring equipment before job !

11. Adequate hose on suction and discharge side of blender !

12. Estimate available fluid removeable from tank !

13. Pressure test all iron at 100 psi above anticipated treatment pressure !

14. All fuel tanks full !

15. Flush all hoses and lines including to wellhead with clean water !

16. Inspect wellhead & piping for any unsuitable low pressure connections !

17. Check/Relief Valve installed properly on Annulus !

CapacityDead Volume

(bottom)

Tank Gauge

before job

Tank gauge at

end of job

Fluid volume

Pumped

Rated HHP of

pumpPlunger Diameter Stroke Capacity, bpm

HHP required

for fract job

04.

05.

Notes

Hydraulic Horsepower = psi x bbl/min x .02456

1

2

3

4

Maximum RPM

0

07.

08.

09.

Pump #

Fracturing Check List #1 - Rig Up

Tank #

01.

02.

5- 4" hoses on suction req'd, 1

per 5 bpm

3 - 4" hoses on discharge req'd.

03.

Available Fluid

On Site Test Pressure

10.

06.

Pump #

2

3

4

1

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

5/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 5 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Location :

Date :

Item Check

Equipment Needed on Job Site !

01 Workover program !

02 Treatment program !

03 Well logs with collars and perforatons indicated !

04 Steel tank gauge tape !

05 Engineer's handbook and calculator !

06 Service Company reference tables !

07 Containers for samples and felt tip marking pens !

have 100 500 ml or 1000 ml containers on hand !

08 5 gal pail for forced closure flow back rate gauge !

09 Quality control forms !

10 Viscometer and hot water bath !

11 Water test equipment

pH paper !

themometer !

iron test kit !

phosphate test kit !

total dissolved solids tester !

reducing agent tester !

chloride test kit !

The Day Before the Job

01 Sufficient tank capacity for entire job? Volume Required _____ bbl !

02 Tanks clean? !

03 Water potasium chloride and sodium chloride content OK? !

04 Tanks full? !

05 Water Clean? - take dipper sample from each tank !

06 No leaking valves on tanks? !

07 Pre-gel quality control of frac fluid conducted? !

08 Fill out quality control tables 1,2,3,4,5 !

09 Sand bins full? !

10 Correct sand type? !

11 Check sand for f ines !

12 Review sand and fluid schedules with service company supervisor !

13 Additives on location? !

14 Densitometer on location and functioning? !

15 Review rig up check list !

16 Arrange for testing of gelled fluids !

17 Arrange for receipt of tables 1,3,6,7,8,9,10 2 hours before pump time !

18 Establish maximum treating pressure _____ psi !

19 Calculate expected surface treating pressure _____ psi !

Fracturing Check List #2 - Supervision

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

6/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 6 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Location :

Date :

Item Check

01 Review sand and fluid schedules with service company supervisor !

02 Review Rig Up check list and Day Before the Job check list !

03 Receive and discuss Quality Control Tables 1,2,3,4,5,6,7,8,9,10 !

04 Volumes will be recorded as clean _______ or dirty (includes sand) _______? !

dirty volume bbl = clean volume bbl + (lb. sand x .00109) !

05 Finalize pumping schedule on Table 8. !

06 Gauge all tanks after mixing gel and rolling tanks. Use Table 4 !

07 Tank numbers organized in the order that they will be drained? !

08 Review with service company supervisor and treater consequences !

of losing suction on blender

09 Gauge sand volume in bins. Use Table 5 !

10 Fill in Table 8 !

11 Fill in Table 6 !

12 Fill in Table 9 !

13 Fill in Table 1 for each tank of gelled fluid !

14 List which additives will be added on the fly:

a. BF-7L !

b. XLW-56 !

c. GBW-12 !

d. !

15 All tanks premixed with necessary additives? !

16 For crosslinked gel, sample each tank and add crosslinker to check for cross linking !

17 Fire fighting equipment on location !

18 Pump during daylight hours only. !

19 Check Casing PSV properly installed and valves properly positioned !

20 Hold pre job safety meeting in a quiet location where everone can hear. !

Designate safe gathering area. !

Take head count of all personnel on site. !

Wear hearing and eye protection, hard hats, safety shoes. !

Post Job Review and Summary

Plan Actual Plan Actual Plan Actual

01 Fluid Volume, bbl

02 Sand, lb

03 Additives used:

a. X-Cide 102 (gal)

b. KCl (lbs)

c. GW-27 (lbs)

d. BF-3 (lbs)

e. NE-18 (gal)

f. BF-7L (gal)

g. XLW-56 (gal)

h. GBW-12 (gal)

i.

j.

Step Rate Test Mini Frac Main Frac

Fracturing Check List #3 - Just Before the Job

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

7/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 7 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Tank

NumberType Fluid

Fluid

Temp.

(deg F)

pHChlorides

(ppm)Clean?

Iron

(ppm)Sulfate TDS (ppm)

Reducing

Agent

(+ or -)

Acceptable Levels

pH 6 - 8 Chlorides < 20,000 Bacteria nil

Temp 60 - 90 Iron < 20 ppm TDS < 50,000

Clean Yes Reducing Agent Negative

Tank

NumberpH

Chlorides

(ppm)Viscosity

Base Gel ( Linear Gel ) Analysis - Table 2

Step Rate Test

Main Fract

Type F luid Fluid Temp. (deg F)

Base Fluid Water Analysis - Table 1

Step Rate Test

Mini Fract

Crosslink Time (min)

Main Fract

Mini Fract

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

8/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 8 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Percent

On

Percent

On

Percent

On

Percent

On

Percent

On

Percent

On

Percent

On

* The amount that can be pumped out of tanks will vary. You normally will leave 30 - 50 Bbls

0Total

Frac Tank Tracking Chart - Table 4

Step Rate Test and Mini Frac

Tank No.

Main Frac

Total

Gauged Volume in Tank

(Bbls)

Pumpable Volume* in

Tank (Bbls)

Volume on Location After Treatment

(Bbls)

Tank No.Gauged Volume in Tank

(Bbls)

Pumpable Volume* in

Tank (Bbls)

Volume on Location After Treatment

(Bbls)

Step Rate Test

Mini Fract

35

Compartment No.

Proppant Type

Sieves Size

8

16

20

25

30

14

Proppant Sieve Analysis - Table 3

140

Pan

60

80

100

120

40

10

12

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

9/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 9 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Total Volume: Buffer On site (BF-7L) : bbls

Cross-linker On Site (XLW-56) : bbls Breaker On Site (GBW-12) : bbls

Cross-linker Addition Rate : Breaker Addition Rate :

XLW - 56

(gals)

GBW - 12

(gals)BF - 7L (gals)

XLW - 56

(gals)

GBW - 12

(gals)BF - 7L (gals)

Mini Frac

Main Frac

Stg #

Total Cross -

linker Used :Mini Main

Total Breaker

Used :Mini Main

Buffer Used :

Volume Remaining

StageStage Volume

(gals)

Compartment No.

01

02

Volume Used

Total Proppant Used :

Type ProppantGauged Quantity In

Compartment (lbs)

0

Proppant Remaining After

Treatment (lbs)

Proppant Tracking Chart - Table 5

Cross-linker and Breaker Tracking Chart - Table 6

0

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

10/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 10 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Type of Fracturing Fluid : Type of Proppant :

Amount of Fracturing Mini Main Amount of Proppant Mini Main

Fluid on Location

Beginning of Job : Beginning of Job :

End of Job : End of Job :

Type of Prepad & Flush Pre-Job Time: Mini Main

Safety Meeting

Amount of Prepad and Flush on Location Remarks : Mini Main

Beginning of Job :

End of Job :

Products Added on the Fly: Products Batch Mixed:

Job Recap: Mini Main Job Recap Mini Main

Average Rate, BPM ISIP psi

Average Pressure,psi Frac Gradient, psi/ft

Maximum Rate, psi Total Proppant pumped, lbs

Maximum Pressure, psi Total Fluid to Recover, bbls

Remarks:

Mini

Main

Job Started :

Job Completed :

Treatment Information

Job Summary - Table 7

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

11/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 11 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Cross-

linked

Fluid

Volumes

Sand

Volumes

Mini

Main

Stg #

Salts Added: type: Amount / 1000gal

Base Gel: type: Amount / 1000gal

Cross - linker : type: Amount / 1000gal

Bactericide : type: Amount / 1000gal

Surfactant : type: Amount / 1000gal

Buffer : type: Amount / 1000gal

Breaker : type: Amount / 1000gal

Fluid Loss : type: Amount / 1000gal

Salts Added: Type Amount / 1000gal

Base Gel: Type Amount / 1000gal

Cross - linker : Type Amount / 1000gal

Bactericide : Type Amount / 1000gal

Surfactant : Type Amount / 1000gal

Buffer : Type Amount / 1000gal

Breaker : Type Amount / 1000gal

Fluid Loss : Type Amount / 1000gal

Type

Salts

Base Gel

Biocide

Surfactant

Buffer 1

Buffer 2

Amount Pre-job

Fluid Type :

Base Fluid :

Amount Post-job

Proposed Pumping Schedule - Table 8

Frac Fluid Components - Table 9

During Treatment Checks

Stage Type FluidClean Stage

Volume

Dirty Stage

Volume

Proppant

Concentrati

on (ppg)

Proppant

Stage

Volume

lbs

Proppant

Remaining

(lbs)

Fluid Type :

Base Fluid :

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

12/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 12 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Frac Via Tubing Casing Annulus Lower Upper

! ! ! Casing Volume to perf:

Lower Upper

Total Flush Volume:

Casing Size & Weight : Lower Upper

Size: inch Weight: ppf Perforations:

Lower Upper Lower Upper Lower Upper

SITP SICP ISIP

Tested Frac Lines To : psi Pressured Tubing-Casing Annulus To: psi

Time Fluid TypeClean Volume

(bbl)

Dirty Volume

(bbl)Rate (BPM)

Casing Pres.

(psi)

Sand Conc.

(ppg)

Fracture Treatment Summary Sheet - Table 10

Remarks

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

13/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 13 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Test No. : Test No. : Test No. :

Fluid Type : Fluid Type : Fluid Type :

Temperature : Temperature : Temperature :

Bob Size : Bob Size : Bob Size :

RPM : RPM : RPM :

Time

(mins)Dial Reading App. Vis.

Time

(mins)Dial Reading App. Vis.

Time

(mins)

Dial

ReadingApp. Vis.

Test No. : Test No. : Test No. :

Fluid Type : Fluid Type : Fluid Type :

Temperature : Temperature : Temperature :

Bob Size : Bob Size : Bob Size :

RPM : RPM : RPM :

Time

(mins)Dial Reading App. Vis.

Time

(mins)Dial Reading App. Vis.

Time

(mins)

Dial

ReadingApp. Vis.

Breaker Loading Tests - Table 11

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

14/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 14 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Frac Equipment Data

Size Brand

Recommend

Min. Wall

Thickness

Lowest Wall

Thickness

Avg. Wall

Thickness

Operating

PressureTest Pressure Test Date

BJ Equipment

Surface Equipment

Treatment line:

Straight joint - 12 ft 3" SPM 0.220 0.264 0.297 15,000 22,500 2001

Straight joint - 10 ft 3" SPM 0.220 0.304 0.514 15,000 22,500 2001

Straight joint - 8 ft 3" SPM 0.220 0.320 0.332 15,000 22,500 2001

Straight joint - 6 ft 3" SPM 0.220 0.372 0.387 15,000 22,500 2001

Pup joint 3" SPM 0.220 0.326 0.428 15,000 22,500 2001

Pressure relief valves: 3" x 3" BJ 15,000 22,500 2001

3" x 2" SPM 15,000 22,500 2001

Manifolds:

Check valves: 3" SPM 0.330 0.922 1.052 15,000 22,500 2001

Y lateral 3" SPM 0.360 0.655 1.280 15,000 22,500 2001

Double wing chiksan - 3 way 3" SPM 0.330 0.562 0.626 15,000 22,500 2001Single wing chiksan - 3 way 3" SPM 0.330 0.544 0.644 15,000 22,500 2001

Single wing chiksan - 2 way 3" SPM 0.330 0.499 0.649 15,000 22,500 2001

Hummer valve (fullbore) 3" SPM 15,000 22,500

Hummer valve (fullbore) 2" SPM 15,000 22,500

Densitometers 3" TEXAS 15,000 22,500

Master valve (plug type): 3" SPM 15,000 22,500

Downhole Tools:Packers:

CST 4-1/2" Wheaterford 10,000

CST 7" Wheaterford 10,000

RBP

PSTG2 4-1/2" Wheaterford 10,000

PSTG2 7" Wheaterford 10,000

JOB Equipment

Size BrandOperating

PressureTest Pressure

Surface Equipment

Wireline/ Slick line equipment:Stuffing box 3" Otis 10,000 15,000

Lubricators: 3" Otis 5,000 10,000

2-1/2" Otis 5,000 10,000

Slick Line BOP: 3" Otis 5,000 10,000

Master valve:

Gate valve 3" 5M: 3" Baker 5,000 10,000

Adapter Flanges, 3-1/16" x 11" x 3M: R-31/ R-45 3,000

Union Couplings, EU: 3-1/2" 6,980 6,980

Pipe Nipple (J-55, 9.5 ppf, EU): 3-1/2" 6,980 6,980

Tubulars:

Frac tubing, 9.3 ppf, J55, EUE: 3-1/2" 6,980 6,980

Casing:

K55, API standard 4-1/2" - 11.6# 5,350 5,350

K55, API standard 4-1/2" - 13.5# 9,020 9,020

K55, API standard 4-3/4" - 16.0# N/A N/A

K55, API standard 6-5/8" - 20# 4,180 4,180

K55, API standard 7" - 20# 4,360 4,360

K55, API standard 7" - 23# 4,980 4,980

Packer:

CST 7" - 17 - 23# 10,000

HD 4-1/2" 9 - 13# 7,000

6-5/8" 17 - 23# 10,0007" - 17 - 23# 10,000

RBP: 4-1/2" 9 - 13# 7,000

6-5/8" 17 - 23# 10,000

7" - 17 - 23# 10,000

Equipment

-

8/19/2019 05-5 SOP - Hydraulic Fracturing.pdf

15/15

TEKNIK PRODUKSI NO : TP.05.05

JUDUL : STANDARD OPERATING

PROCEDURESUB JUDUL : Perawatan Sumur dan Kerja-Ulang

Khusus Pengasaman, Fracturing dan

Perforasi

Halaman : 15 / 15

Revisi/Thn : 2 / Juli 2003

Manajemen Produksi Hulu

Frac Layout

Remarks:

1 1 1 1 1 1 1 8 1 : Tank

2 : Blender Engine & Panel

3 : Liquid Addit ive System

4 : Mixing Tube

5 : Sand Auger

6 : Sand Silo

7 : Pump

8 : Ground Pit9 : Check Valve

2 3 4 5 6 10 : Frac Van

2" Bleed off Line 11 : Main Treating Line

12 : Master Valve

13 : Relief Valve

14 : Radioactive Densitometer

15 : Pressure Transducer

7 7 16 : Flexible Hose

9 9 17 : Bleed Off Valve

7 7

9 9

15

14

13

12 10

15

11

Well

16

16

16

16

16

17