030 home tests.pdf

-

Upload

hasan-mehedi-pial -

Category

Documents

-

view

219 -

download

0

Transcript of 030 home tests.pdf

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :1/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

SUBJECT

This instruction describes the methodology of home tests on finish product.

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :2/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

CONTENTS

1. PREREQUISITE 2. MATERIAL

3. TESTING

3.1 - Square meters 3.2 - Colour fastness 3.3 - Appearance after washing 3.4 - Dimensional stability 3.5 - Twisting 3.6 - Nickel detection 3.7 - Accessories tensile strength

4. HOME TEST CONCLUSION 5. WASHTAG

Page 3

3 - 4 4 5

5 - 7 7

7 - 8 9

10

10 - 11

11

11

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :3/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

1. PREREQUISITE

For each production, home testing must be done on every colour of production samples. If possible, take articles in the smallest size produced or those with a defect. Remark: If the wash care symbols don’t permit to use washing machine, the sample must be sent to an agreed laboratory to make a dry clean test.

2. MATERIAL

Precise circular cutter, allowing 100cm² to be cut. Scales precise to 0.01g allowing weight up to 600g. KIABI marking gauge Pistol and plastic ties Scissors Washing machine type A1 (drum with horizontal axis & front loading) example: « SIEMENS » reference WH51080 Tumble dryer example: « SIEMENS » reference WT58030 Powder detergent: type IEC Extra load: polyester or cotton Greyscale for colour change: reference A02 in half grades Greyscale for colour staining: reference A03 in half grades Light box with lamps:

- Daylight D65-6500°K, - Ultraviolet UV-365Nm, - Standard filament F-2700°K - Commercial lighting 1000 lux

Multifibre samples ISO / DIS 105 F10 made up of: wool, acrylic, nylon, cotton and acetate. Fabric swatch in 100% cotton reference ISO 105 F09. Normalised crockmeter Measurement tape Graduated ruler from Kiabi marking gauge

Voir

DQUA_023

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :4/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

Iron Head way calibre Nickel detection kit: Model 284 from James H. HEAL Cotton swabs Knife or scraper or a file Dynamometer (minimum of 30Kgf) Kit of grips for EN71.1 (snaps, button, ….)

3. TESTING Washing Fix with plastic links the multifibre sample onto each article to be washed. Weigh and add an extra load to obtain a total lead of at least 2kg. Weigh 50g of detergent for each washing cycle. Choose the washing cycle relative to the care label. if hand wash, select the appropriate washing machine program. Drying Choose the drying method relative to the care label. Flat drying Lay out the material on a smooth and horizontal surface, eliminate any folds by hand without stretching non deforming the fabric and leave it to dry in the fresh air. Machine drying Choose the drying cycle relative the care code and include the same extra load.

Voir

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :5/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

3.1 - Square meters SOP Must be done before washing. Position the fabric or the article completely flat without deforming it on the surface of the cutter. Exercise a pressure on the cutter and turn the handle clockwise several times. Weight evaluation

Place the cut out fabric on to the scales.

Write the weight on the washtag.

3.2 - Colour fastness

To washing SOP for shading Cut one rectangle of 5 x 10cm for evaluation of colour shading.

Place side by side the washed material sample and the unwashed rectangle sample, in the light box on the same plane and in the same sense. Place parallel and on the same plane the grey scale relative to colour shading. Evaluation of the shading These evaluations are done using daylight D65 of the light box.

Evaluate the difference between the two samples by comparing them with the different variation levels on the grey scale.

The staining index is the one which presents an equivalent contrast on the grey scale.

Repeat this evaluation operation two or three times and when possible, validate your judgement by a third person.

Mark the result on the washtag.

Voir

DQUA_031

DQUA_031

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :6/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

SOP of the staining The stain rating is done on three materials from the multifibre fabric (cf. Point 7 Laboratory tests). Place side by side the two multifibre samples (washed and unwashed) in the light box on the same plane and in the same sense.

Place parallel and on the same plane the greyscale relative to colour staining. Evaluation of the staining Evaluate the difference between the two multifibre samples by comparing them with the different variation levels on the grey scale.

The staining index is the one which presents an equivalent contrast on the grey scale.

Repeat this evaluation operation two or three times and when possible, validate your judgement by a third person.

Staple the multifibre sample and mark the result on the washtag. To rubbing

SOP

The test is done using the crockmeter to give ten rubs in the warp direction and ten rubs in the weft direction, on independent reference sample fabric swatches.

The sample is rubbed with a reference sample fabric. Four tests are done :

- one using a dry sample fabric in warp, - one using a dry sample fabric in weft, - one using a wet sample fabric in warp, - one using a wet sample fabric in weft.

For a printed fabric, the test must be repeated as above to include all the colours.

Place side by side the samples used for the test and a virgin sample fabric in the light box in the same plane and in the same sense.

Place parallel and on the same plane the grey scale relative to colour staining. Staple the four samples used on the test report with the 'weft' and 'warp' direction and the state 'wet' or 'dry' printed clearly; then indicate the results on the washtag.

Voir

IQUA_020

DQUA_031

DQUA_031

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :7/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

Evaluation This evaluation is done using daylight D65 of the light box. Evaluate the difference between the samples used for the test and the virgin sample by comparing them with different variation levels on the greyscale; then write the result on the washtag

3.3 - Appearance after washing Check the resistance and functioning of the accessories marking any observations on the washtag.

Check the quality of prints marking any observations on the washtag. WARNING: Colour staining for products manufactured with several colours with one or more light colours (ex: red and white).

3.4 - Dimensional stability

SOP before washing It must take into account if necessary the front opening of the article. The operation follows these rules:

Mark the back and the front(s) (see sketch),

Place the links at more than 2cm from any seam, retaining the largest possible distance,

Fix the plastic links to obtain at least two height measurements and two width measurements (initial measurements).

Voir

DQUA_031

DQUA_031

DQUA_031

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :8/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

Evaluation Measurements are taken after the full washing, drying and if necessary ironing cycles. In the case of very crumpled fabric (ex: viscose), it must be ironed, without misshaping the material, before taking any measurements. Take the measurements using a measurement tape. Apply the following formula to calculate the dimensional change: Final Measurement - Initial Measurement x 100 = Dimensional change in %

Initial Measurement

Example Initial Measurement = 23 Final Measurement = 20

Dimensional change = 20 - 23 x100 = -13%

23 The changes will be negative if the « Final Measurement » is smaller than the « Initial Measurement », and positive in the opposite case. Write the changes in % on the washtag.

Voir

DQUA_031

D

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :9/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

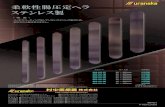

3.5 - Twisting

The method which permits to determine spirality is the following: - Measure the distance “ D ” (to nearest 1mm) from the natural dried fold on the fabric

square to the inner edge of the seam for top items (see diagram). For pants items, measure the distance “ D ” from the natural dried fold and the inside leg seam. On garments these measurements are made at the hem.

- Calculate the percentage spirality i.e: 100 x “ D ” / L

L corresponds to:

- underharm to hem length after washing for top items. - inside leg seam after washing for pants items.

Example : D = 2cm L = 39cm Twisting = 100 x (2 / 39) = 5,13 % Write the changes in % on the washtag, section « others ».

Voir

DQUA_031

L

D L

D

New side seamNatural fold line after washing

Original side seam

Original inside leg seam

New inside leg seamNatural fold line after washing

L

D

L

D L

D

L

D

New side seamNatural fold line after washing

Original side seam

Original inside leg seam

New inside leg seamNatural fold line after washing

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :10/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

3.6 - Nickel detection SOP Take the metallic part to test. With the knife or the file, in case of coating on, scrape the metallic part to do the test directly on the metal. Clean the metal part. One end of the cotton swabis moistened with 2-3 drops of the supplies solution from the detection kit. The swab is then rubbed for about 15 seconds, against the part to be test. Evaluation If the colour of the swab turn to “PINK”, it confirms that nickel has been released from the surface of the accessories. Write the result on the washtag. Keep the used cotton swab in the home test report as specimen. Important safety precautions Store the kit in a dry place. Do not swallow the solution. Avoid contact with the eyes. Skin should be thoroughly washed with water, after accidental contact with test solution.

3.7 - Accessories tensile strength SOP Determine the accessories to be tested.

For Babies 0 to 3 years : all buttons, snaps and accessories must be tested. For children and adult : all functional accessories which are submit to a strong and repetitive tensile must be tested (buttons, snaps, …).

Reminder: For Babies items (0/3yrs included), a laboratory test is compulsory.

Voir

DQUA_031

HOME TESTS Identification IQUA_030

Date d’application 2014 Jul 01

NORMES QUALITE KIABI Indice C

Page :11/11

Approbation

Date : 2014 Jul 01 Signature : E.NAJAR

F01 Propriété de la Société S.A.S KIABI EUROPE reproduction et diffusion interdites.

Prepare the dynamometer with the appropriate grips. Fix the accessories with the grips. Put in tensioning the part to be tested. Reset the dynamometer to zero. Start the test and increase slightly the loads until the appropriate value (see the below chart of the loads), with a constant speed of extension (if electronic dynamometer the speed is 50mm/mn). Once the dynamometer reach the maximum loads, keep the loads during 10 seconds.

Chart of the loads Type of article Size of accessories Maximum loads

Babies 0 to 3 years included ≤ 6mm 50 Newtons

Babies 0 to 3 years included > 6mm 70 Newtons

Children + Adult All 90 Newtons Evaluation If the element still attached to the article and the fastening isn’t damage, then the test is OK. If the element detached during the test , then the test is not OK (REJ). If after visual inspection we consider that the fastening of the element is damage, then the test is not OK (REJ). Write the result on washtag.

4. HOME TEST CONCLUSION If a home test comes failed, the production has to be stopped in waiting to correct the defect detected during home test.

Once the default is corrected, a new home test should be performed. Samples must be pick up in the factory by the Service Provider.

Suppliers must be responsible to provide the correct samples for testing.

In case of disagreement with the supplier, a lab test could be requested to confirm the defect.

5. WASHTAG

Once completed, the washtag is analysed (accept/refuse) and archived in the product file.

Voir

DQUA_031

DQUA_031