· Preservation-. Maintenance-. Sea fasetning. ... · Moon Pool Equipment(Winch/Trolley) ......

Transcript of · Preservation-. Maintenance-. Sea fasetning. ... · Moon Pool Equipment(Winch/Trolley) ......

www.etoms.co.kr

www.etoms.co.kr

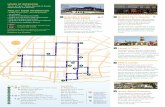

Emergency Exit

Layout

T.302

T.503

T.303

T.303

C3

C2

C1

C4

D/W

Toilet

Kitchen

Repre. Rm

Repre. Rm

C5

T.50

2T.

301

T.201 T.501

Refr.2

Refr.1

Sink Table

Panel

HA

T.305

T.305

T.304

T.304

T.205

T.504

T.202

T.204

T.206

T.203

D2

D1 MeetingRm1

MeetingRm2

Down

복사기

복사기

D/W

02

www.etoms.co.kr

Safety Training

TRAINING

EQUIPMENT TRAINING

NEW EMPLYEES ALL EMPLYEES WORKING PARTS

TOOLCRANEFORK LIFT

03

www.etoms.co.kr

We give many thanks to your management for inviting us to participate the presentation meeting.

We are a total solution company that providing all needs of our client in the shipyard.

Such as Manpower, Material Management, Construction Execution, Quality Control, Commissioning, Punch List Completion, Equipment

Maintenance, Change order, Equipment Store and Transportation, and Offshore Hook Up & Commissioning Specialized Company.

In majority, including of our management and leaders are either former or experienced specialists in deferent fields in DSME and SHI for over

15~30 years, and are ready enough to benefit to your projects. We will be pouring of our utmost for our client in Safety, Quality, Delivery time,

and Cost wise, rather than the benefits to the shipyard.

A. SAFETY FIELD :

· We will be reaching of the ‘Safety Zero Point (Accident free, Injury free)’ by our experiences in various on/offshore.

· We will prevent all potential accident and injury by making of the manual and setting of the ‘Risk Element 30 points’.

· We will prevent all potential accident and injury by tightening up the daily local safety patrol activity.

· Danger predication training, JSA, Tool Box Talk, PTW and execute ‘Areal Safety Person In Charge’ System.

B. QUALITY FIELD : We are planning to be achieved of “zero defect project” by our past quality management experience.

· We are planning to execute quality control by using in actively ‘Pre-qualification system’ focusing proactive quality management system.

· We are planning to minimize quality defects by using in actively ‘Project control system(PCS)’.

· We are planning to secure ‘Quality Basis’ by using in actively DSME Offshore Quality Standard.

· We are planning to minimize ‘Receiving inspection punch’ and ‘FAT Punch’ in advance.

· We are planning to secure best quality by having close relation with ABS, Lloyd, BV Class society.

Greetings

04

www.etoms.co.kr

C. DELIVERY FIELD :

· Drawing review in Engineering relates and manages drawing delivery schedule.

· Control PND in shipyard tightly and in case of delaying of equipments make up emergency plan to do in the future.

· Keep & maintain daily production control & commissioning schedule according to shipyard production schedule.

D. COST FIELD :

· As you know very well nowadays offshore field is overload. This means that it is difficult to find our proper people. And then TOMS will mobilize the manpower from ship

yard people who have much more experienced that present.

· If you don’t mind, we hope to get “lump sum contract” and “long term contract” so that we may lower the cost as total solution company like “No mark up except special service work”

· Remain competitive price by maintaining a family company system with our current family companies. Such as Hi-Air Kservice Korea, E-Tec, Sung-Il SIM, Jung-Woo

Enterprise, Raon Enterprise, ISSAC, JH Co., Ltd. Dong-Bang Ship Machinery, Panapina, Young-Heung Enterprise, Sung-Ha Enterprise, Seoul Inspection Co., DSEC, Ocean

ENG, Prime Tech, Hae-Myung Co., and so on

In addition to, we are going to work harder and harder for maintaining our client’s benefit against the shipyard because two party are being same boat.

Johan Park from TOMS Co., Ltd.

05

www.etoms.co.kr

Top Offshore

Marine ServiceContents

Core Value · · · · · · · · · · · · · · · · ·

Organization Chart · · · · · · · · · ·

Manpower Service Works · · · · · · · · · ·

Commissioning Works

Job Descriptions · · · · · · · · · · · ·

Work Procedure · · · · · · · · · · · ·

Relationship · · · · · · · · · · · · · · · ·

FMS · · · · · · · · · · · · · · · · · · · · · · ·

Experience · · · · · · · · · · · · · · · · ·

Certification · · · · · · · · · · · · · · · ·

Assisting Company · · · · · · · · · ·

Vendor Registration Status · · ·

Factory & Logistic · · · · · · · · · · ·

CEO Profile · · · · · · · · · · · · · · · ·

07

08

09

10

15

16

20

21

22

24

25

26

27

06

www.etoms.co.kr

Think about something pleasant

with TOMS..

PASSION TRUST VALUE

Work with Passion Trust Each OtherCreate

Value Together

SAFETY ON TIME DELIVERY

HIGH QUALITY

CLIENT SATISFACTION

CORE VALUES

07

www.etoms.co.kr

Organization Chart

Company Leader Johan, Park 010-5223-9207

Safety Coordinator Young-Jong, Lee 010-9689-4661

Project Coordinator Mr. Daniel Cho 010-7259-7478

Manpower Service- Structur & Welding- Piping & Machinery- Painting & PFP- HVAC Inspector- Administrator

Material Suply Part-. Spare Parts-. Order Material-. Preservation-. Maintenance-. Sea fasetning

Punch Killing Works-. Job Card Order-. Change Order-. Vendor punches-. OFE punch works

Pre-Commissioning-. Loop Check-. D.Precomm Check-. RFCC confirmation-. Machinery check-. Electric Check

Commissioning-. Menhatan Sky Line-. PCS System Control-. "A" punch close out-. C & E Test-. Black out Test

08

www.etoms.co.kr

MANPOWER SERVICE WORKS

ManpowerService Inquiry

Fixed manpower

- Structure & Welding

- Painting & PFP

- Piping & machinery

- HSE inspectors

- Insulation & HVAC

- Administration part

TOMS

Mobilization

- CVs’ Review

- List up CVs’

- I nterview internal

for Candidates

CLIENT

Submit CVs’ to Client

COMMISSIONING WORKS

CommissioningSchedule

ManhattanSky Line

MechanicalCompletionCertificates

MC Stage

Loop Test,Electric Test,Mechanical

Pre-com Test,Completion

Ready for commissioning

Certificate

Close “A”Punches

Pre-Com Stage

a. Cause & Effects Test

b. Black Out & Sequence Test

a. Operation & Test Procedures

b. Commissioning Test Record

Commissioning

09

www.etoms.co.kr

JobDescriptions

MC & PUNCH CLEARANCE

2010.01.01 – 12.31MC & Pre-Commissioning, Cable pulling, Dressing & Connection work in SHI yard.

2010.01.01 – 02.30Punch works of DR Turbine Gen & Comp.for BP Skarv Project in SHI Yard

2009.11.01 – 12.31Punch works of Flengco Ningbo for BP Skarv Project in TOMS Yard

10

www.etoms.co.kr

PRE-COMMG’ & COMMISSIONING

MC external test, Calibration, Function test, Troubleshooting, Loop test

· Fire & Gas System· All sorts of instrument and Packages

within HVAC System· Fire Water System Open Drain System· Lighting System Pre- MC & Commissioning· LV ESD System MC & Commissioning

· M/C Check & Pipe hydro leak test

· D/G System/ Fire Fighting System/Cooling System

· Bilge System Commissioning

· Hoisting/Pedestal Crane Commissioning

· Provision Crane/Davit Commissioning

· Hydro System : Ring Line Commissioning

· Drilling System(Drawwork & PRS &Top Drive & R/T)

· Commissioning

· Moon Pool Equipment(Winch/Trolley) Commissioning

· Deck Crane Commissioning

· Mud System & Pump Commissioning

· Ballast System Commissioning

11

www.etoms.co.kr

JobDescriptions

MODIFICATION WORKS

PRESERVATION & MAINTENANCE

General Service · Grease Filling in Accordance with Procedure · Equipment Package Cleaning · Remove a Rust & Rust Prevent Work · Self Check in Accordance with Preservation Action Card

DOO SUNG RIG in 2008 on offshore

Dust Collector Install & Bulk system modification Shall Shaker Remodeling Mud Dryer Install with Conveyor

PROTECTION(BEFORE WORKING)

INSTALLATION(DURING WORKING)

PROTECTION(AFTER WORKING) PROTECTION

CONDITIONFOR MECHANICAL PACKAGE

PRESERVATION ACTION CARD

12

www.etoms.co.kr

FLANGE MANAGEMENT

Management Procedure· Pre-Engineering· Work Preparation· Construction & Inspection· Documentation

CLIENT

1. Verify the FM data from TOMS Engineering

2. Commence the Pre-engineerign as per Priority Order of Piping Works or Schedules.

3. Create Joint Data Sheet and Disrtibute to FM Work Groups.

TOMS

Production

/ CM

1. TP list with Line List Review ans Verification

2. Provide Subsystem Base or Area Base Piping Work Completion Schedule (Priority Order)

TOMS

Quality

1. TP List with Line List Review and Verification2. Co-ordination & Support for Pre-engineering

TOMSPiping

Engineering

1. Provide TP with Line List (Excel format) with Relevant Organization

1.1 QM 1.2 Client 1.3 FPSO/Rig/Drillship Production 1.4 CM2. Provide Piping Test Pack to

CLIENT 2.1 Hard Copy 2.2 PDF Format (If Applicable)

Input the Piping Data into FM

System Creat Work Package

Provide Work Schedule

Co-ordination & Support

Provide Piping Data and Test Pack

Nobody wants to see leak!!

13

www.etoms.co.kr

JobDescriptions

PROCUREMENT SERVICE

BOX

BOX

NITROZEN RACK PLATFORM MOVING PLATFORM

BOTTLE RACK

CONTAINER

OIL TANK

OFFSHORE BASKET TANK

BOTTLE RACK

VERTICAL LADDER HAND RAIL DERRICK RACK

· Customised materials can be made· Offshore containers, baskets and tanks are certified by DNV 2.7-1 / EN 12079

14

www.etoms.co.kr

WORK PROCEDURE

· FLANGES(FF, RF, RJF, LTG, STG), FITTINGS(ELBOW, REDUCER, TEE, COUPLING, UNION, CAP, CROSS, STUB-END), VALVES(GATE, BALL, GLOBE, BUTTERFLY, DIAPHRAGM, CHECK, TRUNNION) PIPES, STEEL PLATES

· Customised materials can be made

FLANGES

VALVES

FITTINGS

PIPES

COMMUNICATION

REQUESTINQUIRY

OFFERQUOTATION

SUPPLY

easy going

15

www.etoms.co.kr

Report

Royalty/Order Keep/Criteria

Prevent

RelationshipRELATIONSHIP WITH BOTH PARTIES

Contract Auditing Tool Production

CLIENT TOMS DSME

Specification

Drawings

HSE Plan

Quality Plan

HSE, JSA, PTW, TBT

QA/QC / OJT

Project Control Sys

Daily Conference

Hull Side

Top Side

Accommodation

Hel-Deck

16

www.etoms.co.kr

JobDescriptions

STRUCTURE & PAINTING FIELD

PIPING & MECHANICS FIELD

· WE can mobilize them who have 10 - 30 years experience of offshore

division in DSME and SHI.

· Mr. D.S Ahn has many experience of structure & painting field in DSME &

SHI as supervisor.

· Mr. J.H. Lim has many experience of structure & painting field in DSME &

SHI as supervisor.

· Mr. S.I. Lim has many experience of structure & painting field in DSME &

SHI as supervisor.

· Mobilize supervisors who have 10 - 30 years experience of offshore division

in DSME and SHI.

(Please refer to the attached TOMS Keymembers herinwith)

· TOMS has worked Flange Management System of Gorgon for Chevron in

HHI as Supervisors.

· Design & drawing to review ; mandatory requirements, interfaces

· Specification to review for building up quality procedures/standard &

ITP

· Establishment of quality management system for project

· Preparation of WPS ; WPQT & WPQR

· Welder qualification, NDE Plan ; to define vital points

· Paint schedule to review & monitor, Material tracibility

· ITP for structual steel work & painting

· Demension control procedure ; to define vital point to hold

· Detailed assembly process ; to define holding point for attention for

safety & material tracing purposes

· Heavy lifts handling procedure and In-line quality control

· Drawing review & Preparation how to build & construct the said project

· Make-up FMS inspection package & preparation of Inspection

procedures from Hydratight

· Preparation of wleder’s PQ & NDE Map review

· Material tracabilities, PMS and documentation control

· WPS Preparation & approval works

· FAT and test results folow up

· Hydro test and leak test preparation

· Offshore DSQS review and application of it onboard

· Maintenance & preservation procedure for equipments

· FAT & Receiving inspection punch killing & control

1. Supervisors & Inspectors 1. Supervisors & Inspectors

2. Work activities

2. Work activities

17

www.etoms.co.kr

ELECTRIC &INSTRUMENT FIELD

PIPING & MECHANICS FIELD QUALITY CONTROL

· Mobilize supervisors who have 10 - 30 years experience

of offshore division in DSME and SHI. (Please refer to the

attached TOMS Keymembers herinwith)

· Joined the contruction works of COE & AD project for

ExxonMobil in DSME as Supervisors.

· Mobilize supervisors who have 10 - 30 years experience

of offshore division in DSME and SHI.

(Please refer to the attached TOMS Keymembers herinwith)

· TOMS has worked Flange Management System of

Gorgon for Chevron in HHI as Supervisors.

· Drawing review & Preparation how to build & construct

the said project.

· Cable pulling schedule, connection diagram, single line

diagram, Equpment layout review

· Loop diagram(P& ID), Loop folder, Logic diagram review

· Mechanical completion list(Project control system)

· Cable bending radius check(6-10D) and Cable tray

overfilling check

· Power & control cable segregation check

· Maintenance & preservation procedure for equipments

· FAT & Receiving inspection punch killing & control with

PCS

· High voltage “Hi-po test” procedures review & confirm

· Cause & effects test procedure review & confirm

· Drawing review & Preparation how to build & construct

the said project

· Make-up FMS inspection package & preparation of

Inspection procedures from Hydratight

· Preparation of wleder’s PQ & NDE Map review

· Material tracabilities, PMS and documentation control

· WPS Preparation & approval works

· FAT and test results folow up

· Hydro test and leak test preparation

· Offshore DSQS review and application of it onboard

· Maintenance & preservation procedure for equipments

· FAT & Receiving inspection punch killing & control

1. Supervisors & Inspectors 1. Supervisors & Inspectors

2. Work activities 2. Work activities

· Mobilize supervisors who have 10 - 30 years experience

of offshore division in DSME and SHI. (Please refer to the

attached TOMS Keymembers hereinwith)

· Joined the contruction works of COE & AD project for

ExxonMobil in DSME as Supervisors.

· Shipyard’s quality plan review & confrim

· Welding process sequence(WPS) check

· Welder list control & NDE Map Check

· Hydro tech procedure & Leak test check

· FAT and test results folow up

· All test results and documentation control

· Daily inspection & weekly inspection control

· PCS(Project control system) Control

· FAT & Receiving inspection punch killing & control

1. Supervisors & Inspectors

2. Work activities

18

www.etoms.co.kr

HSE FIELD HVAC FIELDFLANGE MANAGEMENT SYSTEM(FMS) FIELD

· Mobilize supervisors who have 5 - 10 years experience

of offshore division in shipyards.

(Please refer to the attached High Air Service Korea

Co., keymembers hereinwith)

· Joined the contruction works of COE & AD project for

ExxonMobil in DSME as Supervisors.

· Please refr to the attached MOU between TOMS and

Hi-Air Service Korea hreinwith.

· Mobilize supervisors who have 10 - 30 years experience of offshore in HHI,

DSME and SHI. (Please refer to the attached FMS Keymembers herinwith)

· TOMS has worked Flange Management System of Gorgon for

Chevron in HHI as Supervisors.

· Vendor drawing review & confirm

· HVAC work package review & confirm

· MC check sheet confirm

· Balancing test procedure review & confirm

· Volume test procedure review & check

· Temperature shut down test procedure reviw & confirm

· Cause & effects test procedure review & confirm

· Check that the installed lines are in accordance with the latest ISO

& P & ID drawings.

· All welding inspection, stress reliese and NDT are to be completed

and recorded it on sheet.

· Check that all materials on flange joints are installed properly as per

drawing & specification.

· Check all pipe supports are installed in place as per design.

· Check that all pipe work flushing & hyrostatic test shall be

completed and recorded on sheet.

· Check that all pipe works shabe installed & reinstalled in

accordance with the current P & ID.

· Check all dimension of gap, sag and distance as per drawing & specification.

· Face of flanges & gaskets shall be controlled & cleaned and not

damaged during installation face.

· Hydrailic & hand torque tools shall be calibrated by the concerned

institues as per auditing term.

· Check that bolts length of flange joints shall be correct.

· Bolt tensioning to be torqued according to the value of procedure.

· All data shall be recorded on FMS certificate as attached hereinwith

1. Supervisors & Inspectors

2. Work activities

1. Supervisors & Inspectors

2. Work activities

· Mobilize supervisors who have 10 - 30 years experience

of offshore division in shipyards. (Please refer to the

attached TOMS Keymembers hereinwith)

· Joined the contruction works of COE & AD project for

ExxonMobil in DSME as Supervisors.

· Shipyard’s HSE Plan review & confrim

· HSE basic items training procedure(4 hrs) review & confirm

· Confined space safety training procedures review & confirm

· Harness safety training procedure review & confirm.

· PTW(Permit to work) safety procedure review & confirm

· JSA safety procedure & TBTalk safety procedure review &

confirm

· Block lifting up safety procedure review & confirm

· Argon gas welding safety procedure review & confirm

· Scafollding safety working procedure review & confirm

1. Supervisors & Inspectors

2. Work activities

19

www.etoms.co.kr

FMS(Flange

Management System)

FMS(Flange Management System)

FLANGE CERTIFICATE for NO.

Bolt Torque Tightening Record-Flange Test Pack No:

Isomatric No.Bolted

Joint No.Piping Class

Flange Size (inch)

Bolt ∮ (Q’ty)

Bolt Length (mm)

Flange Type

Torque Value(Nm)

Verified by Worked by Date

ISO Dwg NO. Line No.

Executed by Construction QC Client QACompanySignature

Print NameDate

DO Action Stage Confirming StagePreparation Stage

Check Drawing Check Support as per Drawing Check Bolts Tightening

FMS Plan & Procedures Check In-Line (Gap/Sag/Distance) Record All Data on FMS Cert.

Lecture Plan for DSME Tech Check Flange & Gasket Material Apply Flushing and Hyd. Test

Check NDE & Welding Check Face Cleaning/Damage Apply N2 & He Leak Test

20

www.etoms.co.kr

ExperienceExxon Mobil Feb. 2012 - PresentSakhalin-1 Project (COE, Arkutun-Dagi)

Human Resource Service

Petroserv Feb. 2012 - Jan. 2013SSV CATARINA Drilling Rig Project

Procurement & Installation Service

QGOG Mar. 2012 - Oct. 2012Amaralina and Laguna Star Drillship Project

Procurement & Installation Service

Swire Pacific May. 2012 - Oct. 2012Pacific Orca Project

Procurement Service

Chevron Jan. 2012 - PresentGorgon Project

Human Resource Service

OOG Sep. 2011 - Apr. 2012ODN I, II Project

Procurement Sevice

ETESCO Jul. 2011 - Nov. 2011ETESCO VIII Drillship Project

Procurement Service

BP Jun. 2009 - Feb. 2011Skarv Project

Human Resource & Procurement Service

Odfjell Mar. 2009 - Feb. 2010 GVA 7500 Project

Human Resource & Procurement Service

Seadrill Jul. 2008 - Nov. 2008East Aquarius Project

Human Resource Service

21

www.etoms.co.kr

Certifications

HI-Air Korea MOU The Contract with Exxon Mobil

22

www.etoms.co.kr

Recommendation Letter The Contract with BP

The Contract with HYDRATIGHT Safety Award from BP

23

www.etoms.co.kr

AssistingCompany

No. Company Name Major Work Address Tel

1 Hae-Myoung Enterprise Piping 1198-2, Jangpyeon-Dong, Geoje-Si, Gyeongnam +82-(0)10-8506-8183

2 Mi Rae Electric 45-5, Jangpyeong-Dong, Geoje-Si, Gyeongnam +82-(0)10-3269-1148

3 Geum Yeong ENG Electric 30-1, Hwangseong-Dong, Nam-Gu, Ulsan +82-(0)52-227-7817

4 Jeong Woo Steel Outfitting 530, Jangpyeon-Dong, Geoje-Si, Gyeongnam +82-(0)55-630-3758

5 CT Korea Painting 1862, Sinyong-Ri, Georyu-Myeon,, Goseong-Gun, Gyeongnam +82-(0)55-638-4775

6 E-TEC Heat Tracing2F, Dreamfactory Bldg, 134-2, Jangpyeong-Dong, Geoje-Si, Gyeongnam

+82-(0)55-632-8422

7 Dae IL Insulation 890, Aju-Dong, Geoje-Si, Gyeongnam +82-(0)10-9655-1838

8 Tae Jeong Scaffolding 530, Jangpyeon-Dong, Geoje-Si, Gyeongnam +82-(0)55-630-4007

9 Dae Gwang TEC Hull Structure 655, Gangju-Ri, Beopsu-Myeon, Haman-Gun, Gyeongnam +82-(0)55-582-5816

10 Ocean Engineering Engineering5F, Ja Young Bldg., 967-26, Gohyeon-Dong, Geoje-Si, Gyeongnam

+82-(0)55-363-8015

11 Prime TECH Engineering 991-24, Gohyeon-Ri, Sinhyeon-Eup, Geoje-Si, Gyeongsnam +82-(0)55-635-2821

12 DB Holdings Hyd Test 2F, 1101-21, Jukto-Ri, Yeoncho-Myeon, Geoje-Si, Gyeongnam +82-(0)55-633-6574

13 Sung IL SIM Piping 1027, Yuhyoun-Ri, Gunbuk-Myeon, Haman-Gun, Gyeongnam +82-(0)55-583-0307

14 Hi-Air Korea HVAC 1432-1, Damahn-Ri, Jinrae-Myeon, Kimhae-Si, Gyeongnam +82-(0)10-6436-5007

15 Raon Enterprise Steel Outfitting #928, Cheongok-Ri, Juchon-Myeon, Gimhae Si, Gyeongnam +82-(0)10-3561-5023

16 Panapina Forwarding 459-3, Jangpyeong-Dong, Geoje-Si, Gyeongnam +82-(0)51-603-3215

17 Sin Ho Business Procurement 722-14, Hakjang-Dong, Sasang-Gu, Busan +82-(0)10-8010-3522

18 Withus Commissioning #15, Jangpyeon-Dong, Geoje-Si, Gyeongnam +82-(0)10-7468-0117

24

www.etoms.co.kr

VendorRegistration

Status

Eni Saipem

Maersk Drilling

Rowan Companies

Hydra Tight Exxon Mobil QGOG OOG

Pacific Drilling

Halliburton

Registration Date and Code : Aug. 2011 / S01630045

Registration Date and Code : Aug. 2012 / 43706

Registration Date and Code : Jan. 2013 / 2014572

Registration Date : Mar. 2012

Registration Date : Sep. 2011

OURCLIENT

Petroserv Ocean Rig ETESCO ENSCO MI SWACO

25

www.etoms.co.kr

Factory& Logistic FACTORY #1

FACTORY #2

LOGISTIC

• Total Area : 1,500㎡ • Facility : 450㎡

• Total Area : 26,520㎡ • Facility : 1,890㎡

• Total Area : 37,775㎡ • Facility : 19,599㎡

26

www.etoms.co.kr

CEOProfile

TOMS CO., LTD TOMSName : Johan Park (Young-youn Park)

Phone : +82 (0)10-5223-9207

E-mail : [email protected]

Name : Gil-Ho Choi (Philip Choi)

Phone : +82 (0)10-4920-0175

E-mail : [email protected]

After graduating Korea Merchant Marine University, joined STX Pan Ocean shipping company for 6

years as a marine engineer and worked at DSME for 25 years as supervisor, engineer and manager.

Subsequently, applied supervising of piping system for BP Skarv project as supervisor from Jun.

2009 to Feb. 2011.

Have been in charge of commissioning, punch clearance, modification and outfitting work of Drill ships,

Rigs, FPSO and Platforms in the part of mechanical part during last 11 years. Experience with the

entire life cycle of a product, starting from specification analysis and conception, to design, prototyping,

development and feature implementation, to testing, verification, deployment and user support.

Jan. 2012 - Present : Has prepared Flange Management of Gorgon Project for Chevron as project manager.

Jun. 2009 - Feb. 2011 : Worked for BP SKARV project in SHI as Supervisor

Oct. 2008 - Jun. 2009 : Worked for several kind of vendors in SHI & Jacob yard as supervisor

Mar. 2008 - Dec. 2008 : Worked for Sung-jin GO Tech Co. as supervisor

Oct. 2002 - Feb 2008 : Worked for Offshore division in DSME as Junior Director

1) Trial team leader of Drillship project for “Transocean”

2) Trial team leader of Drilling rig project for “Sea Drill”

3) Trial team leader of FPSO project “AGBAMI” for “Chevron”

4) Trial team leader of LPG Tanker project for commercial company

5) Trial team leader of Fixed platform “Sable” project for “Exxon mobile”

6) Trial team leader of Fixed platform “BB” project for “Chevron”

7) Trial team leader of Fixed platform “Kizomba B” project for “Exxon Mobile”

8) Trial team leader of FPSO project “DALIA” for “TOTAL”

9) Trial team leader of Drilling rig “Atlantis” project for “BP America”

10) Quality Manager of Drilling rig “Thunder Horse” project for “BP America”

Oct. 2001 - Oct. 2002 : Worked for Special Ship Division in DSME as General Manager

Jan. 1996 - Sep. 2001 : Worked for Special Ship Division in DSME as Deputy Manager

Aug. 1988 - Sep. 1992 : Joined the supervising team of 209 Class Submarine project for Korean Navy in HDW Germany

Oct. 1984 - May. 1988 : Worked for Commercial Ship Division in DSME for 4 years

Feb. 1979 - Sep. 1984 : Worked as Marine Engineer for 6 years in STX Pan Ocean Shipping

Mar. 2011 - Present : Worked for ETESCO, EXXON MOBIL, QGOG, OOG and PETROSERV as TOMS CEO.

Aug. 2009 - Feb.2011 : Worked for OCEAN RIG, VANTAGE and BP SKARV project in SHI as Managing Director

1) ROV(A-Frame Assembly, Cursor Rail Fabrication) 2) All carry over works3) Punch list clearance 4) Drilling system commissioning5) Deck machinery commissioning

Dec. 2008 - Aug. 2009 : Worked for Transocean Drillship project in DSME as TOMS CEO

Sep. 2007 - Dec. 2008 : Worked for Doosung Rig(Performance Improvement Work) as SAMJIN Co. Commissioning Team Leader

1) Convention and modification for winterization and annual maintenance2) Commissioning for production equipment 3) Under deck platform installation4) Derrick air tubing modification 5) Mud convey system (shaker module)6) Pipe installation work 7) Deck expansion installation

Feb. 2006 - Aug. 2007 : Worked for Agbami & Dalia FPSO project in DSME as SAMJIN Co. Commissioning Team Leader

Jan. 2005 - Jan. 2006 : Worked for Amethyst 1, 2 in DSME as SAMJIN Co. Commissioning Team Member

Jan. 2003 - Oct. 2004 : Worked for BP Thunder Horse PDQ project as SAMJIN Co. Commissioning Team Member

Mar. 2002 - Dec. 2002 : Worked for Exxon Mobil Kizomba-BTLP project in DSME as SAMJIN Co. Commissioning Team Member

1) Drilling system mechanical completion and testing2) Marine utility system pre-comg’ and commissioning(Bilge system, Deck machinery)3) Receiving inspection 4) Equipment alignment inspection5) Punch clearance

Summary Summary

Experience Experience

27